Telsonic AG, recognised as a world leader in the development and manufacture of Ultrasonic Technology for welding, cutting, cleaning and screening, once again demonstrate their commitment to product development and innovation with the launch of the new Telso®Terminal TT7.

This new system from Telsonic is set to revolutionise ultrasonic metal welding applications in a variety of areas, especially within the fast growing Electromobility Sector where there is an increasing demand for the highest levels of quality and process control in cable assembly, terminal assembly and battery production applications.

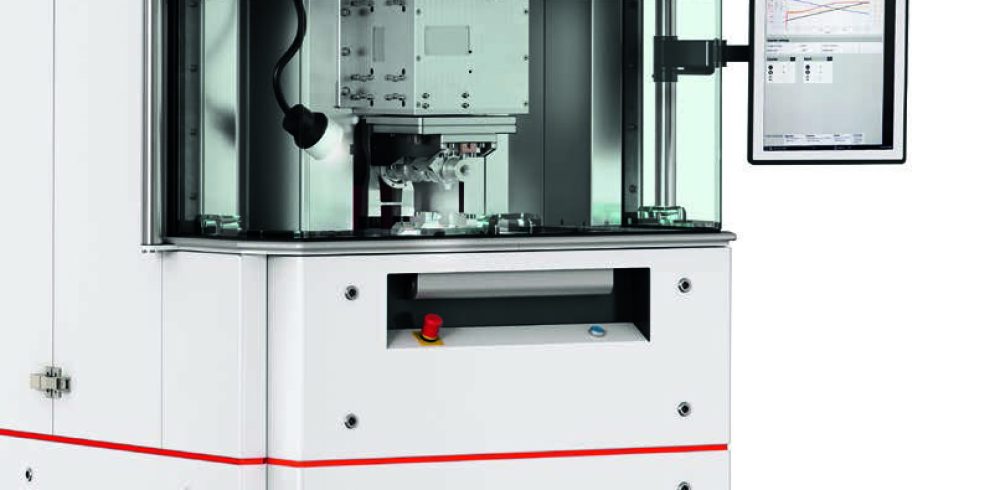

The Telso®Terminal TT7 incorporates the latest version of Telsonic’s proven PowerWheel® welding technology which ensures maximum reliability and optimum process control for welding metal cable cross sections up to 200mm2. Additional benefits include the ability to change tools in under 5 minutes, thanks to the TT7’s new quick-change system. The Telso®Terminal TT7 also features standardised interfaces for digital networking and ease of integration into production systems.

The Telso®Terminal TT7 will make its exhibition debut at Productronica, the World’s leading trade fair for Electronics Development and Production, being held between the 16th and 19th November 2021 in Munich. Telsonic AG can be found on stand B4.319 where representatives will be happy to explain the benefits of the new technology and also discuss specific applications.

The Telsonic Group, headquartered in Bronschhofen (Switzerland), has been providing ultrasonic technology solutions in Europe, America and Asia since 1966. Continuous innovation helps to ensure that, in many applications, the company maintains a lead over competitors, offering added value to users.

With more than 250 highly-qualified staff the owner-managed family company specialises in plastic and metal welding, together with ultrasonic cleaning, screening and cutting. Current trends mean that these skills are in strong demand, e.g. for lightweight construction, electromobility, battery production, the packaging industry, medical technology and 3D printing.