SWISSto12, a leading provider of advanced Radiofrequency (RF) products and telecommunication satellites, has significantly enhanced its production capacity with the purchase of four MetalFabG2 metal 3D printers from Additive Industries.

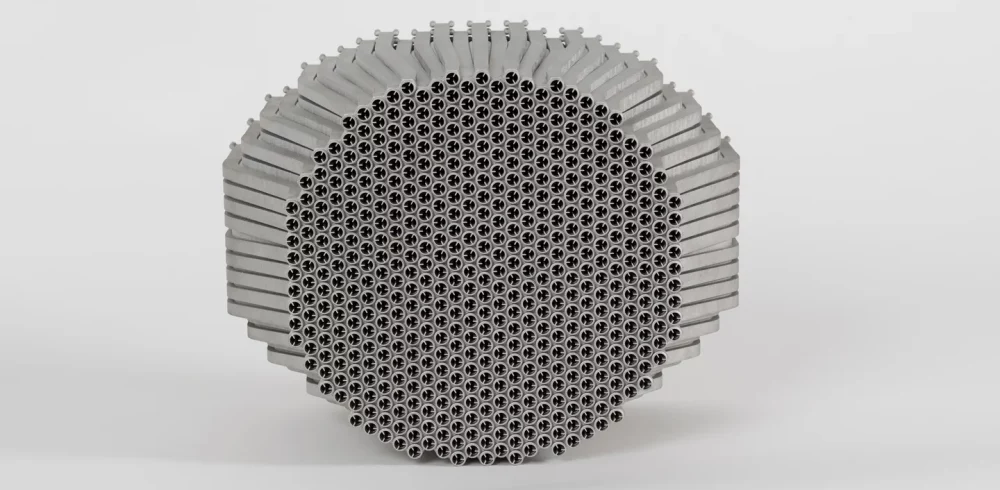

Founded in 2011 as a spin-off from the Swiss Federal Institute of Technology in Lausanne (EPFL), SWISSto12 gained international recognition for its innovative use of precision manufacturing and 3D printing in developing next generation RF products. The company has developed the world’s largest IP portfolio for the use of 3D printing in RF product applications, relying on optimized and complex geometries that make full use of the design freedom of additive manufacturing. Thanks to the novel use of this technology by SWISSto12, integrated RF systems no longer need to be assembled with hundreds of components. By using fewer interconnects and further optimizing their designs these products deliver significant mass savings, enhanced RF performance, smaller form factor and lower production costs. This approach also offers a significant level of affordable customization and reduced lead times. SWISSto12 has qualified this technology to the highest aerospace standards and has successfully deployed over 1000 functional products in space with zero failures.

The MetalFabG2s, are equipped four full-field lasers for maximum productivity. As each and every laser can access and melt material all over the 420mm x 420mm build plate, it enables users to achieve precise geometrical tolerances and the highest laser utilization during every layer of a build process. The large build size of 420mm x 420mm also enables SWISSto12 to push the limits of RF satellite payload performance and create next-generation systems with mechanical and thermal features integrated in large monolithic products, maximizing the value of a reduced part count and mass savings. Out of the four systems procured by SWISSto12, three will be dual-core versions of the MetalFabG2 which incorporate advanced automation features for build set-up, build changeover, build starts, laser calibration, integrated powder handling solutions and advanced scanning strategies. The combination of size, precision and productivity makes the MetalFabG2 a compelling production asset for demanding applications like RF components.

Mark Massey, CEO of Additive Industries, expressed enthusiasm about the collaboration: “We are delighted to announce SWISSto12’s investment in our MetalFabG2s. It is a testament to the trust they place in our technology to meet the exacting demands of their industry. Our metal 3D printers, equipped with four full-field lasers, provide unparalleled precision and automation, making them an ideal choice for SWISSto12’s cutting-edge RF products.”

Emile de Rijk, CEO of SWISSto12, highlighted the significance of the investment: “Our collaboration with Additive Industries marks a milestone in our pursuit of excellence in RF technology and production scale-up. The quality and capabilities of the MetalFabG2s align seamlessly with our commitment to innovation and quality. This investment enables us to service the growing requirements and production volumes for our aerospace customers.”

For more information about the MetalFabG2, see here.

About Additive Industries

Additive Industries is a pioneer in industrial metal 3D printers offering cutting-edge technology that enable customers to adopt, industrialize and accelerate their manufacturing processes. As a company, it helps to solve the challenges of the most forward-thinking industry leaders in highly demanding sectors, including aerospace, automotive, high tech, and energy. The flagship MetalFab printer range includes the MetalFab 300 Flex, designed for early-stage adopters of metal AM technology and the MetalFabG2, a large platform 3D metal powder bed fusion printer optimized for production. Every product can incorporate automated and modular features for build set-up, build changeover, build starts, laser calibration, integrated powder handling solutions and advanced scanning strategies. Headquartered in Eindhoven (The Netherlands), Additive Industries has service and support centers in the USA and Singapore.

About SWISSto12

SWISSto12 is a leading manufacturer of advanced satellite payloads and Radio-Frequency systems, including the HummingSat: a small yet powerful geostationary telecommunications satellite developed in collaboration with the European Space Agency (ESA) through its public-private-partnership program. Its customers include Satellite operators such as Inmarsat and Intelsat, and blue-chip industry leaders such as Thales, Lockheed Martin, and Northrop Grumman.

SWISSto12’s RF products and satellites benefit from the company’s unique and patented 3D-printing technologies and associated Radio-Frequency product designs that deliver lightweight, compact, highly performing, and competitive RF functionality. Besides its space portfolio, the company is also active in telecommunications and aeronautic applications. SWISSto12 owns the largest IP portfolio worldwide around the use of 3D printing for RF product applications.

SWISSto12 has developed commercially with success and is amongst the fastest growing aerospace companies in Europe, with recognition by ViaSatellite as one of the “2024 hottest companies in satellite” as well as a nomination by the World Economic Forum as a “2024 Technology Pioneer”.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News