Polymer Additive Manufacturing of End-use Parts : Evolutionary acceleration of production for the Automotive Industry

Automotive production trends rise and dive at the drop of a hat, swayed by environmental forces ranging from demand to supply chain dynamics. Right now, it’s all about the base trends of electrification, mass customisation, connectivity, propulsion, and efficiency.

Where does polymer additive manufacturing (AM) fit into all of this?

Lightweighting: AM enables production of lighter component parts, in turn enabling a lowering in fuel consumption. Whilst the issue of range is resolved in the development of electric vehicles, this can only be a positive. From optimising topology and overcoming complexity challenges, to generating lattices to improve impact protection whilst removing density, the AM advantage is clear: tooling costs are eliminated; and parts can be simplified (with integration in subassemblies) or enhanced in terms of complexity. Without tooling, production times can be as little as 25% of using more traditional methods of part production.

Personalisation: The ultimate luxury for the luxury car owner – a design delivered to meet the specific delights of the customer. The AM advantage here comes in the form of mass customisation. To personalise every badge or handle on a run of 850 cars through CNC or injection moulding would be wasteful in terms of material, costly in terms of tooling, and time consuming in terms of production. Additive manufacturing enables production of multiple parts where every item on the print bed can be different.

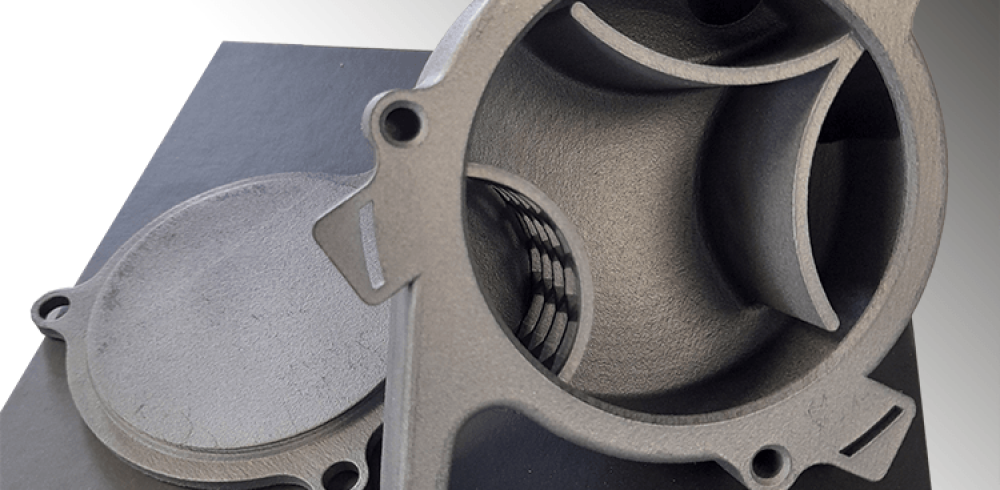

Electrification: The EV revolution is now. And it is not going to stop any time soon. We’ve already mentioned lightweighting and integrating subassemblies to reduce fuel consumption and extend mileage. But it doesn’t stop there. Many of the engineering grade resins and powders designed for AM are heat resistant, chemical resistant and robust enough to enable manufacturers to replace metal with polymers (that lightweighting again) without compromising safety or quality. Furthermore, their thermal properties are ideal for keeping EV Li-ion batteries in optimal conditions for performance. Nylon 12, for example, has an exceptionally low freezing point and a high melting point. It is not inconceivable to produce housing and heat exchange mechanisms quickly and cost efficiently.

There’s a recurrent theme in these additive manufacturing opportunities – that of time saving and cost cutting (tooling is expensive). Ford, an early adopter of polymer additive manufacturing in its Advanced Manufacturing Centre, claimed in 2015 to have ‘saved billions of dollars and millions of hours of work’. 6 years on, and a collaboration with Carbon® to develop engineering resins for its Digital Light Synthesis™ (DLS) technology, has seen billions more in savings.

Here in the UK, the largest fleet of Carbon printers belongs to Paragon Rapid Technologies. With four DLS machines, and two HP Multi Jet Fusion printers, supported by a host of state-of-the-art post processing equipment, Paragon’s AM facility has been providing parts to the UK’s luxury car industry since 2017.

____

To find out how Paragon Rapid Technologies can help with research, design, development and production of ready to use parts, call 01325 333 141 or email: info@paragon-rt.com. www.paragon-rt.com.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News