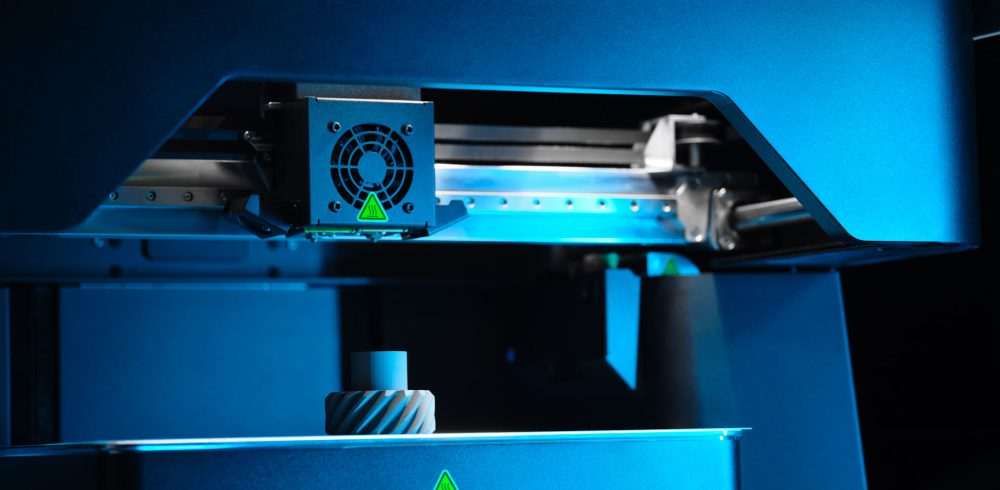

Markforged Holding Corporation (NYSE: MKFG), the company strengthening manufacturing resiliency by enabling industrial production at the point of need, this week announced the FX10 Metal Kit, a print engine that brings metal printing capability to the FX10. With this kit, the FX10 becomes the world’s first industrial 3D printer that can print both metal filaments and composites with continuous fibre reinforcement.

“Customers no longer have to choose between a metal and a composite printer. Years of R&D investment and field experience have come together to provide an all-in-one solution for 3D printing to provide immediate return on investment once installed on a factory floor,” said Shai Terem, CEO of Markforged. “The FX10 supercharges other equipment on the factory floor to be better utilized and run more efficiently, increasing productivity and reducing potential line down events.”

The FX10, released in November 2023 as a composite only printer, was designed to be the most versatile tool on the factory floor and has received tremendous feedback from early customers. With its modular architecture, upgrades like the Metal Kit enable customers of the FX10 to gain additional value from the machine after purchase.

Markforged also announced a new 316L stainless steel metal filament to be used with the FX10 Metal Kit. Users will also be able to print in 17-4PH with additional support for other Markforged metal filaments in the future.

“We designed the FX10 to be a modular platform, so that we are able to release new innovations and upgrades without customers having to purchase a new printer every year,” said Terem. “Along with new software capabilities we release regularly, the FX10 Metal Kit is poised to provide continuously growing value on factory floors for years to come.”

The FX10 Metal Kit consists of a swappable print engine that includes a metal-specific print head, material feed tubes, routing back, and dual pre-extruders. An FX10 can be swapped between metal and composite as many times as needed, and the swap takes about 15 minutes.

Similar to the 5th Generation Continuous Fiber Reinforcement (CFR) print system in the FX10 that prints nearly twice as fast as previous composite printers, the 2nd Generation Metal FFF engine, built on years of Markforged’s experience printing metal, prints significantly faster than previous Markforged metal systems. FX10 combines faster print speed with a print volume twice as large compared to Markforged’s prior industrial metal printers.

Metal prints are built from the metal filament and a ceramic release filament. The ceramic release is extruded as an interface between the part and supports for ease of separation and removal. Once metal prints are complete, they must be washed and sintered in Markforged’s Wash-1 and Sinter-2 solutions. Eiger, Markforged’s slicer and print management software automates the process, including scaling parts to account for shrinkage during sinter.

The Digital Forge is the additive manufacturing platform that enables every aspect of the FX10 and is purpose-built to integrate into existing manufacturing ecosystems. With the Digital Forge, users can share parts across their organization, and monitor fleet performance from a central location.

Markforged will showcase the FX10 Metal Kit at the International Manufacturing Technology Show in Chicago, Illinois from September 9-14 at booth 432305 where it will be printing in both continuous fibre reinforced composites and metal.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News