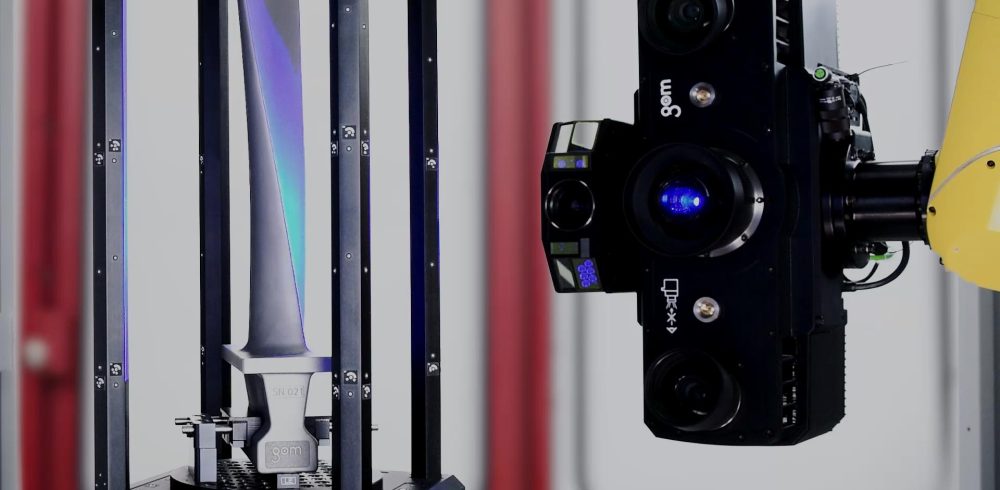

New for 2018 the ATOS 5 and ATOS 5X are the latest high-speed systems of the ATOS family, welcomed by GOM. The robust sensors are fast and precise following the introduction of new features and developments.

The Blue Light Equalizer has been especially developed for the light source in the ATOS 5 to make the systems independent of ambient light conditions. The ATOS 5X takes this a step further with the introduction of a laser light compressor to generate ultra-bright light for the scanning process. More speed and light in the cameras allows for a shorter exposure time, with scan times down to 0.2 seconds per measurement and 100 frames per second, ATOS 5X gives optimal high-speed high precision data capture.

“Enjoying an owner-manager-development unit in control of both software and hardware means that our technology can be released when it is absolutely ready and not just when it suits the shareholders. The speed and overall performance of these latest sensors is allowing us to deliver great data for the most challenging applications,” said Andrew Cuffley, Managing Director at GOM UK.

As a result of this new technology both systems achieve high-precision data for a diverse range of manual and automated applications, from tools and moulds to plastic and metal parts. With the ability to scan small scale items such as aerofoil components up to full car body inspection, the ATOS 5 is flexible and capable over multiple applications.

At the same time, fixture design can be simplified as a larger surface is captured and fewer reference points are required. During the measuring procedure, acquisition times of down to 0.2 seconds are reached.

The trend for automated measuring is supported by installing the ATOS system inside an ATOS Scanbox. This option combines all the functions in one automated measuring machine. By utilising the Virtual Measuring Room software, the measurement environment is represented in a virtual simulation. All robot movements are stimulated and checked for safety before being performed in the actual environment.

Five technology leaps were made before the latest generation of ATOS sensors were developed. Process application and increased process reliability are paramount for the latest and future applications.