Sustainability is the challenge for manufacturers and engineers across UK industries as it impacts production processes, material choice, supply chain, product features and end of life plans. We spoke with AME-3D’s Managing Director, Rich Proctor, to explore the benefits of prototyping and how this can meet a company’s sustainability goals.

Product development process

During the product development cycle there are the following phases: research, design, prototyping, initial production, full scale production, maintenance, and phase out. During development, the cost of changing the design is much more efficient than once a product has hit volume. From both a financial and environmental standpoint, the key is to develop products that serve their purpose and function.

The first consideration in product development needs to be an understanding of the necessity of the product. Does the idea solve a problem?

The second consideration is whether the product achieves the solution as efficiently as possible? This is also where sustainability goals fit in. Is the design elegant, simple and easy to use? Or is it clumsy, overengineered and full of unnecessary features that use resources and energy?

Spending time in research informs the first consideration, then design and prototyping shape the response to the second and enable you to plan the journey using sustainable manufacturing.

Sustainable Manufacturing

Sustainable manufacturing is a broad topic but here are some areas that can have an impact in the product development process.

Material selection

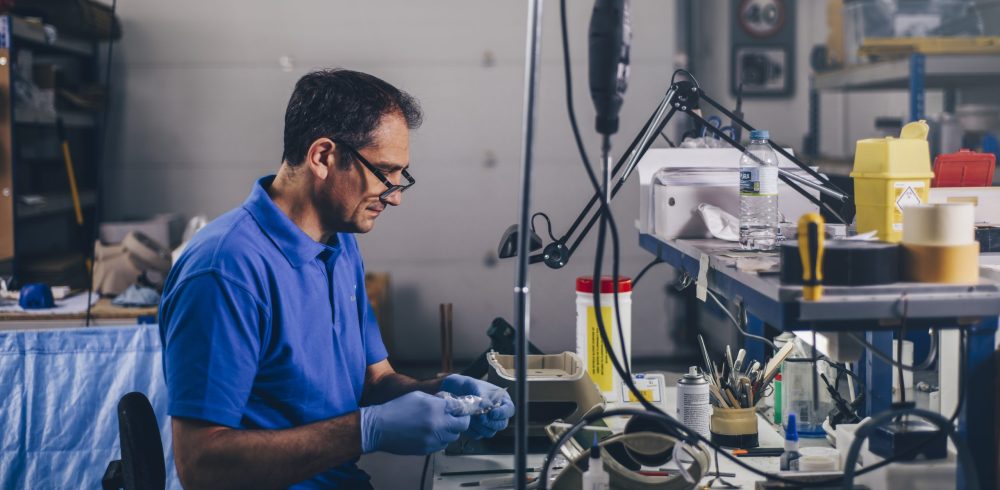

In the design and prototyping phases, exploring the different material options is key. Exploring these alongside trialling and physical testing will highlight what’s available to you. Selecting a more sustainable material for an application may mean that some of the design needs refining. This is why prototyping is so important.

Manufacturing solution

Your manufacturing method needs consideration. Injection moulding for plastics and machining or fabricating for metals have been the go-to methods for many years. Now, there are other options, increasing in popularity. Additive manufacturing and 3D printing a viable production solution for many if considered carefully and designed with this in mind.

Additive manufacturing processes open additional benefits like material reduction and light weighting. Parts can be designed to require less material. With additive manufacturing you only use the material you need rather than machining it away. Additionally, when parts are lighter, they take less energy to handle and ship.

Modular design

Another benefit of additive manufacturing is the ability to only produce what’s required, when required. This modular design lends itself to extending the life of the product. Spare sparts that are easy to replace and disassemble and individual parts suitable for recycling can be designed and refined. This makes the product more appealing to consumers and results in less waste.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News