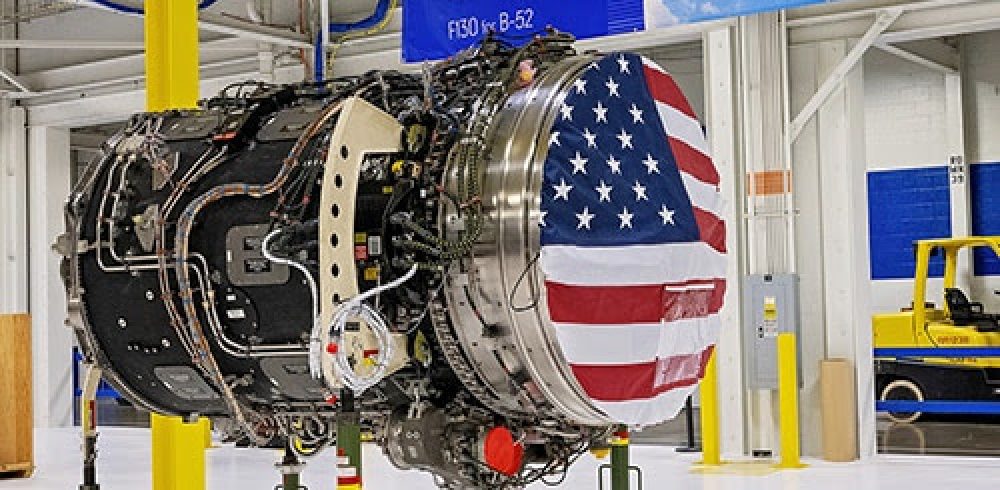

Rolls-Royce (LSE: RR., ADR: RYCEY) today announced testing on the F130 engine has begun in Indianapolis, another step towards delivering for the United States Air Force B-52J Stratofortress. Sea-level testing of the First Engine to Test (FETT) will run the initial software release for the F130 in the newly refurbished Test Cell 114.

In addition, Rolls-Royce is wrapping up successful Rapid Twin Pod Tests this week. Testing at NASA Stennis marked the first time F130 engines were tested in the dual-pod engine configuration of the B-52 aircraft. The tests produced critical performance data, validating Rolls-Royce’s analytical predictions — including performance in crosswind conditions, and further de-risking the integration of the F130 engine onto the B-52J.

Testing at NASA Stennis has played a key role in meeting initial testing goals and delivering at exactly the pace defined by the Air Force. This test data informs the production configuration of the F130 engine Critical Design Review (CDR), on schedule for the fall of 2024.

Candice Bineyard, Director, Early Life Cycle & Naval Programs – Defense, said:

We are thrilled to take the next step forward in the program with F130 sea-level testing in Indianapolis. To date, our testing program has confirmed our predictions and allowed us to stay on track to deliver this fixed price contract for the Air Force. The F130 engine has demonstrated incredible dispatch reliability, which will translate to lower lifecycle costs for the B-52, as well as improved fuel efficiency. As we kick off testing in Test Cell 114, we want to thank our partners at Boeing and the Air Force as we move forward in the program together.”

Test Cell 114 is a state-of-the-art facility with capability to support a range of development testing and production acceptance. Rolls-Royce recently revamped the test cell as part of a $1 billion investment in modernizing its Indianapolis facilities to deliver innovation and advanced manufacturing to the Air Force and other customers with American labor. The F130 engines will be manufactured, assembled and tested in Indianapolis, Rolls-Royce’s largest production facility in the U.S.

The F130 engines will extend the life of the B-52 aircraft for 30 years. The engines are so durable, they are expected to remain on wing for the remainder of the aircraft life. The F130 is derived from the Rolls-Royce BR family of commercial engines, with over 30 million hours of operation and a high reliability rate. It’s a proven, dependable engine that has been in production for 12 years with more than 1,000 engines flying today.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News