In today’s globalised and rapidly evolving business landscape, disruptions to manufacturing are inevitable. However, some are so unpredictable that they can have a catastrophic impact. Natural disasters, geopolitical tensions, trade disputes and global pandemics can all severely impact the stability and reliability of the supply chain, but there are steps that can be taken to help reduce risks. Here, Jerry Sanham, Business Development Director at Filtronic, a designer and manufacturer of RF-to-mmWave components and subsystems, explores how dual sourcing your hybrid manufacturing requirements can help.

Dual sourcing involves procuring goods or services from two or more independent suppliers, providing resilience and minimising the potential risks associated with single-source dependencies by ensuring a consistent supply of essential components and materials. Dual sourcing also offers the potential for faster lead times, scalability and the opportunity to rapidly increase or decrease volumes without incurring extra costs.

The right choice of second-source partners can solve a lot of headaches. When partners collaborate, they share best practices and leverage their collective experience gained from previous contracts in similar applications. By working together on continuous improvement initiatives, both parties can achieve real-time benefits such as cost reduction and maximisation of yields.

For example, a leading European defence OEM made a strategic decision to dual source transmit and receive modules (TRMs) with Filtronic, so that they could avoid the risks associated with single-sourcing and build a more resilient supply chain. Under this specialist manufacturing services agreement, Filtronic manufactured a total of six distinct versions of the TRM design and shipped more than 160,000 of these modules, which were specially tailored for use in active electronically scanned phase array (AESA) radar systems. Since the first order, Filtronic has won multiple contracts with the same client and is now considered an integral supply chain partner.

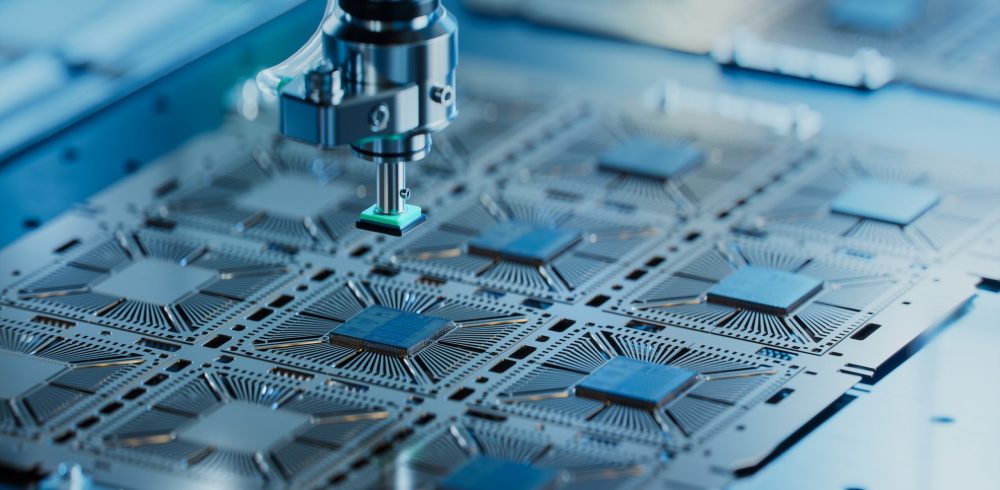

They originally chose Filtronic as they excel in hybrid manufacturing — the manufacturing process of integrating miniaturised electronic circuits that incorporate both individual devices and passive components. Filtronic has a rich history of integrating these components into hybrid electronic circuits at our advanced manufacturing facility in the UK , minimising their size and weight, whilst increasing their power.

Recent investments in Filtronic’s hybrid manufacturing capabilities have further enhanced its hybrid assembly and semiconductor packaging capabilities.

Dual sourcing of hybrid manufacturing enables diversification of your supply chain. By leveraging the advantages of using a market leader in hybrid manufacturing, companies can achieve enhanced resilience, cost-effectiveness, and improved yield and quality.

In an increasingly dynamic and challenging business landscape, the adoption of this strategy enables manufacturers to stay ahead of the competition, satisfy customer demands, and navigate unforeseen disruptions. As the industry continues to evolve, embracing dual sourcing will be crucial for manufacturers to thrive and deliver superior products to their clients.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News