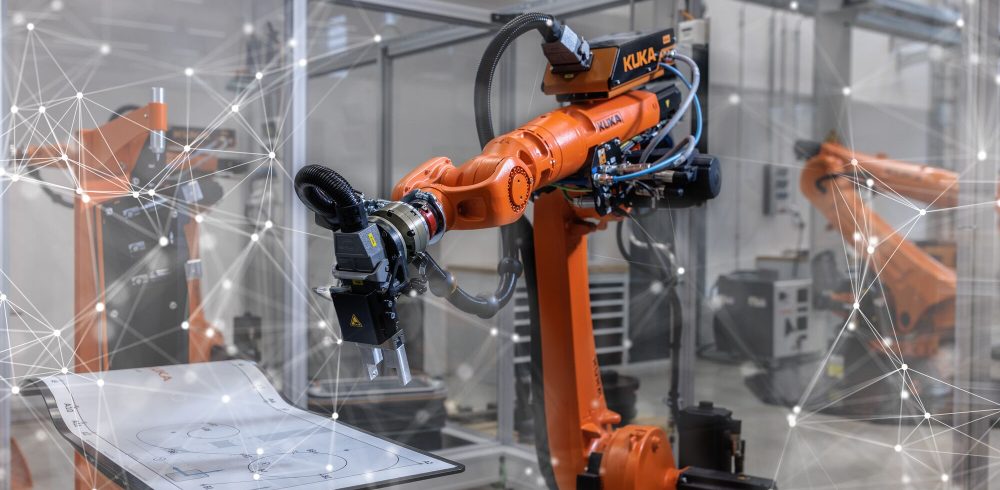

We sit down with KUKA UK’s Marketing & Strategy Director, Neil Mead, to discuss how manufacturers are using the latest robotic solutions to tackle labour shortages, improve efficiency, and reduce costs in a competitive industry.

Labour shortages are forcing the manufacturing sector to look at automation differently. According to Neil Mead, Marketing & Strategy Director at KUKA UK, this is particularly evident in food manufacturing, packaging, and the fast-moving consumer goods (FMCG) sectors, where firms are increasingly turning to robots to fill the gap. It is even affecting skilled trades; with skilled welders becoming harder to find in the job market, automated welding is becoming a necessity rather than a luxury.

However, the landscape is changing. “Today, robots are seen as more accessible than previously,” says Neil. There are more low-cost automation solutions available, and the price of the technology is falling compared to the output of the machine. Interestingly, Neil notes a cultural shift, too: a younger generation of managers, engineers, and decision-makers are proving far more receptive to automation technology. This openness has allowed KUKA to collaborate on solutions in diverse areas, ranging from essential medical research to entertainment and filmmaking.

The value of partnerships For a project to succeed, finding the right system integrator is crucial. KUKA relies on a network of fully trained and certified system partner integrators who hold in-depth knowledge of KUKA products.

By bringing together the necessary hardware—from industrial robots with various payloads to Autonomous Mobile Robots (AMRs)—and utilising their programming and application engineering knowledge, these partners deliver turnkey solutions. It means the end user gets a system that works immediately, backed up by KUKA’s global engineering team.

Minimising disruption A major worry for manufacturers is the downtime required to install new tech. Neil explains that KUKA helps avoid this through careful planning and “offsite integration.” Using digital simulation tools and conducting Factory Acceptance Testing (FAT) offsite means the robot system is built, programmed, and tested before it even arrives at the customer’s facility. It can then be installed and set up quickly, minimising disruption to the manufacturing process.

Don’t run before you can walk When discussing flexible automation and ‘cobots’, Neil points out that the first hurdle is often a misconception about cost. “The investment needed to automate a process is relatively low, considering the positive impact it can have on productivity, with a reasonably short payback,” he explains.

However, KUKA often sees manufacturers wanting to automate their most complex operations first. Neil advises the opposite: prove the technology by automating simpler, end-of-line tasks like packing and palletising first. “In this way, we can gain the trust of the customer in the equipment,” he says. Once those wins are secured, the business can move on to tackle the more complex applications.

Energy is a major cost Sustainability is no longer just a buzzword; it is a bottom-line issue. Neil highlights that energy consumption accounts for up to 40 per cent of the total cost of ownership of a robotic product.

KUKA is tackling this by optimising weight, hardware, and software. Slimmer robot mechanics require less material and energy to move, while new controllers with energy-efficient components can consume up to 60 per cent less energy compared to earlier models. Features like ‘ECO mode’ and intelligent path planning further reduce consumption. Crucially, simulation tools allow customers to see the projected energy consumption of a system during the planning phase, ensuring they choose a sustainable concept from day one.

The future Looking forward, Neil sees ‘digital twinning’ and smart services as the key drivers for the workplace. Tools like KUKA Sim allow engineers to save time and money by developing a product in a virtual environment before commissioning.

This is supported by the my.KUKA digital portal, which gives customers 24/7 access to product data, availability, and software management. “All these services save time,” Neil concludes, “and can boost a manufacturer’s bottom line when costs are climbing.”

To find out more about KUKA’s robot range and software solutions for making automation easier, please visit www.kuka.com.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News