At this year’s Electric and Hybrid Vehicle Technology Expo and Battery Show, ESI Automotive will showcase how new technologies, such as silver sintering can help automotive OEMs achieve up to six times greater thermal conductivity of a die bond in the inverter of an electric vehicle. The event takes place from November 30 – December 2 at the Messe Stuttgart, Germany.

ESI Automotive, a major innovation provider, works closely with global automotive OEMs. The company will demonstrate how this sixfold conductivity increase is enabled by ALPHA® Argomax® silver sintering technology at Booth 4-336.

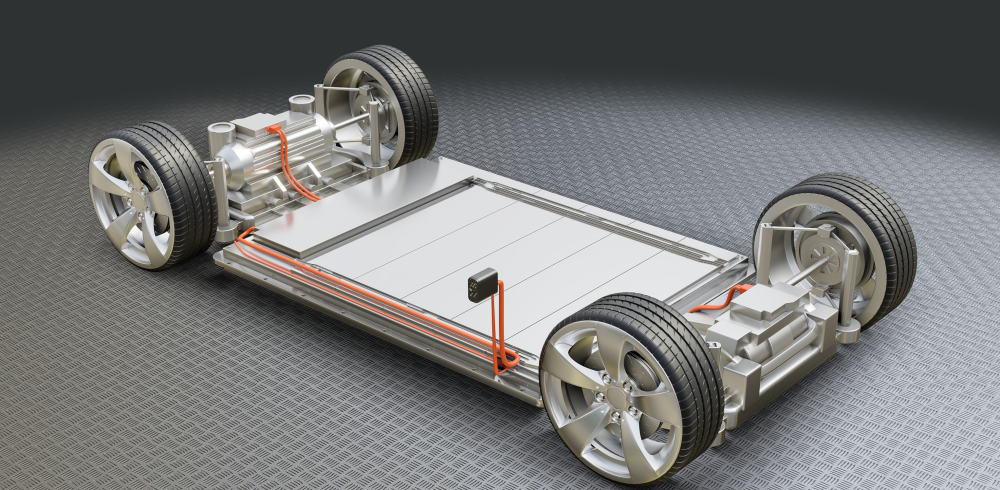

“Through the breadth of ESI Automotive, we are working with OEMs to view their designs and components at a systems level. This enables us to help them enjoy gains in range, power and reliability, through innovative technologies like silver sintering die attach for inverters and thermal management solutions for battery packs,” explained Chris Klok, director of vehicle electrification at ESI Automotive.

“Thermal conductivity is one area where this can make a real difference and is critical for EV, since electric vehicles are more efficient if thermal conductivity in the electric powertrain is improved. ESI Automotive research has shown that silver sintering alone can produce a bulk silver bond with a melting point of 962°C and extremely high thermal conductivity, in the range of 200-300 W/m.K, compared to 26-55 W/m.K for solders.”

Element Solutions Inc acquired the HK Wentworth Group and its Electrolube brand earlier this year. The Electrolube brand adds value to ESI Automotive’s rich portfolio, thanks to its cutting-edge thermal management solutions. Electrolube will be featured on the booth, addressing thermal management solutions with a spotlight on GF600 gap filler.

Working with ESI Automotive, OEMs can now access the broadest range of materials such as silver sintering materials, gap fillers, phase change materials, thermal pastes, thermally conductive encapsulation resins, and surface coatings among others. Across this extensive portfolio of technologies, ESI Automotive is helping vehicle OEMs reduce the risk of field failures through the development of an enhanced and more reliable final product to take to the market.

“As global regulations driven by climate change are pushing OEMs down the EV route and all major manufacturers are embracing vehicle electrification options, it is necessary to view traditional production lines from a systems level and identify where improvements can be made. In-creasing vehicle range, power and reliability remains a key challenge that OEMs are working hard to overcome. At this year’s European Electric and Hybrid Vehicle Technology Expo and Battery Show, we’re looking forward to revealing how our acquisition of the Electrolube brand earlier this year puts us in an even stronger position to partner with OEMs and achieve these goals,” Chris Klok added.