Suitable lubrication can not only increase the lifespan of any motor, but it can also help you to avoid getting burned. Mark Burnett, VP of the Lubricants and Fuel Additives Innovation Platform at NCH Europe, takes the time to explain you why lubrication is so important.

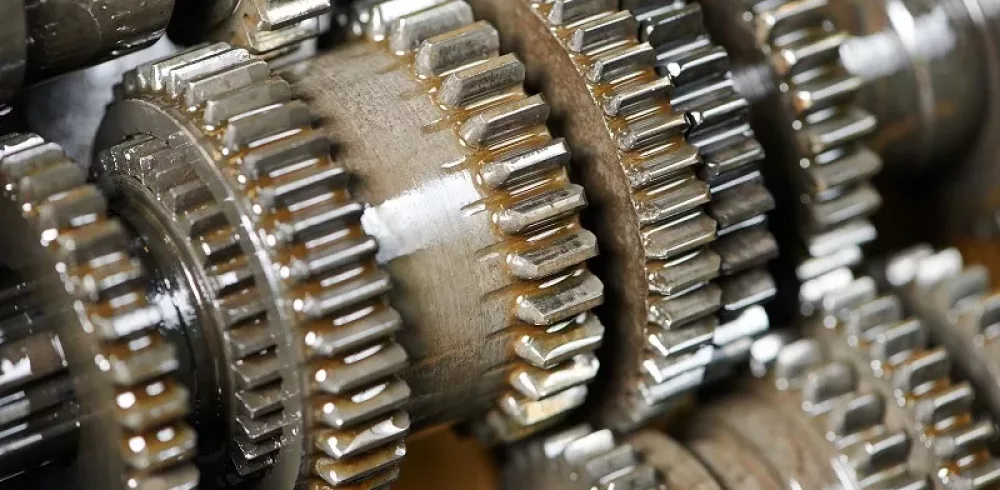

NCH Europe says that 70% of mechanical wear that cause foaming, oxidation and build-up of acidic compounds and sludge occurs because of dry starts. These problems combined with friction will slow down the motor, reduce efficiency in the production line, and affect accuracy. For these reasons, it is important to find an oil or grease, or a combination of the two, lubricant that can annihilate the problems.

Working with high temperatures means there is a need for a lubricant that will not wilt at the first sign of heat. Heat can shorten the life of seals, accelerate oil decomposition, generate the separation of greases, collapse oil films and increase abrasion and scuffing conditions, and encourage microbial contamination. Using oils and greases that contain appropriate additives, such as NCHâs K Nate grease and Top Blend oil, can save you a lot of heartache.

Exposure to water is one of the biggest enemies of lubrication and can reduce its efficiency. The emulsion of the oil or grease in water can lead to oxidation or, even worse, to the destruction of the base stock and the formation of acids. To battle this problem, NCH has developed K Nate grease which is naturally water resistant.

The oil or grease itself can become a problem when you are in a hurry and the lubrication moves away from where it is needed. Looking for something that contains tackifiers and additives is worth it when you know it will stay in place.

Lubrication means you are taking care of your machinery so that it can be at its best for a long time. NCHâs Top Blend for example, contains additives that increase the lifespan of the machinery while giving you less work to do. Make sure you investigate the market and find the right lubrication for you.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News