In industries that work with potentially dangerous gases and substances, the importance of risk-mitigating strategies is critical. High quality HVAC systems can provide peace of mind to those working on shop floors in close proximity to volatile substances, such as hydrogen. Here, Mark Gallifant, Elta Fans Applied Technology’s Business Development Manager, explains how collaboration and teamwork helped solve a critical problem at Helical Technology.

Solving a potentially explosive problem

World leader in the design and manufacture of acoustic and EGR exhaust valves, Helical Technology, has established itself as a market leader for the provision of solutions for problems in the most challenging of conditions.

One such challenge came about in February 2023. Mostafa Koochak, Senior Test Engineer at Helical Technology, was tasked with designing a new test cell at the company’s Warton testing facility. The test cell was intended for testing large diesel engines that go into HGVs, ranging from 12L to 20L in size.

As part of the testing process, hydrogen is supplied to the engines. Being a highly explosive gas and potentially volatile substance, any hydrogen leaks or escapes from the engine must immediately be extracted from the test cell to avoid sudden ignition and explosion to avoid potentially disastrous outcomes.

Blending the past with the future

With extraction of any potential hydrogen leaks a crucial factor, Mostafa set about scoping out the specification of a fan that would sit in a fume hood above the test cell. Helical Technology had previously used Elta Fans in similar projects unbeknown to Mostafa when he initially embarked on this new proposal.

On inspecting a label found within an existing exhaust unit as part of his research, Mostafa found an Elta Fan from 2010. Mostafa then contacted Elta Fans’ Applied Technology sales team to see if they could support in specifying a fan for the new test cell.

Leading the ventilation industry for over four decades and operating across three continents, Elta Fans works with the support of sister companies in Elta Group to deliver a global understanding of the HVAC industry. The specialist division of Elta Fans operates across applications including smoke, hazardous area, gas turbine & more.

From the label of the previous fan used in an older Helical exhaust unit from Elta Fans, the sales team were able to retrospectively advise Mostafa on the specification of the fan before passing him on to Mark Gallifant, Elta Fans Applied Technology’s Business Development Manager, to help specify the new unit for the fume hood. As part of the process, Mark also advised Mostafa with various other elements of the project including the running of calculations and simulations for the air flow pattern in the test cell.

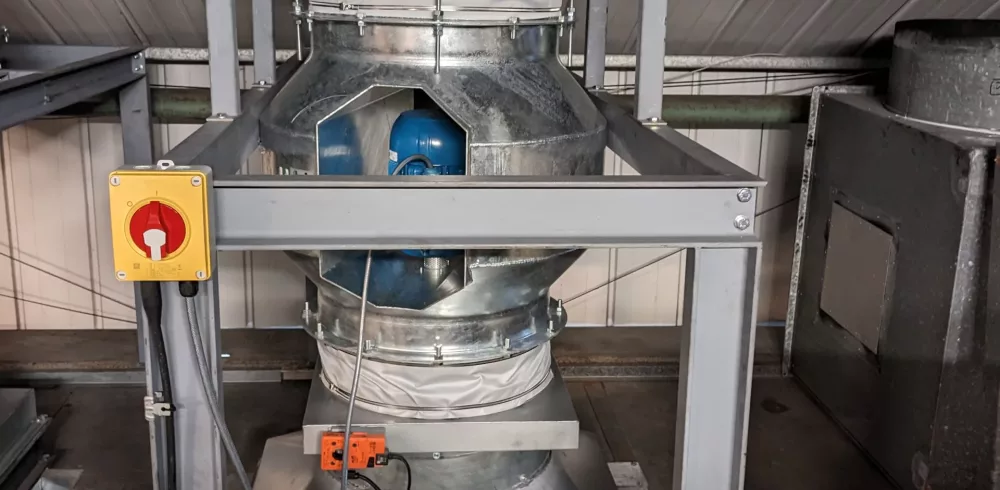

The resulting product of this partnership between Elta Fans and Helical was a bifurcated axial fan designed to sit in the fume hood, continuously running on a ‘low power mode’ during testing to extract fumes as part of a risk-mitigation strategy. If hydrogen is detected, the test cell control system will increase the fan speed to extract the leakage immediately.

The bifurcated axial fan supplied by Elta Fans has a nominal diameter of 560mm and hub size of 150mm with an axial, aluminium impeller. Running at a fan speed of 2,880 r/min and with a motor power of 4.00kW, the fan is capable of moving 3.21 m3/s of air – meeting the necessary airflow performance as detailed by Mostafa.

The fan is now live and in operation at Helical Technology’s test facility, following installation in September 2023, providing constant protection to the test cell and people in the building.

Bespoke, intuitive and responsive

On the success of the collaboration, Mostafa said: “Mark has been unbelievably helpful from the start of the project, going above and beyond in technical discussions to provide accurate calculations and simulations for air flow patterns.

“The sales team at Elta Fans were also incredibly supportive, especially in the early stages of the project. From the label I found on the previously installed fan, they were able to specify retrospective solutions from the get-go. The resulting product is a technically accurate fan used in the fume hood as a crucial risk mitigation strategy.

“It’s clear to me why previous teams at Helical Technology turned to Elta Fans when searching for solutions to challenging and often critical problems. The level of care and attention that I have received in this partnership is unmatched and I look forward to working with the team again.”

For the team at Elta Fans, the project is another addition to an already extensive portfolio of proven results and happy customers. Mark Gallifant commented: “It’s testament to the Elta Fans design process that a fan from over a decade ago is still providing inspiration at Helical Technology for current and future design challenges.

“I’m extremely proud of the Elta Fans team and what we’ve been able to achieve in this project on such a short timeline. From the initial launch of the project in February to delivery of the fan in September, the success and collaboration of the Elta Fans team within the space of six months is astounding and a result of dedicated specialists working together to solve a problem.”

For more information about Elta Fans, please visit https://eltafans.com

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News