Sofitec, a company specialized in aerostructures manufacturing and assembly, is accomplishing the launch of a new area of complex sheet metal processes for the aeronautical industry.

With an investment of 20 million euros, the company began last year the expansion of its facilities, as part of which it has recently acquired two new equipment that will increase its technological capabilities and diversify its products and processes catalogue.

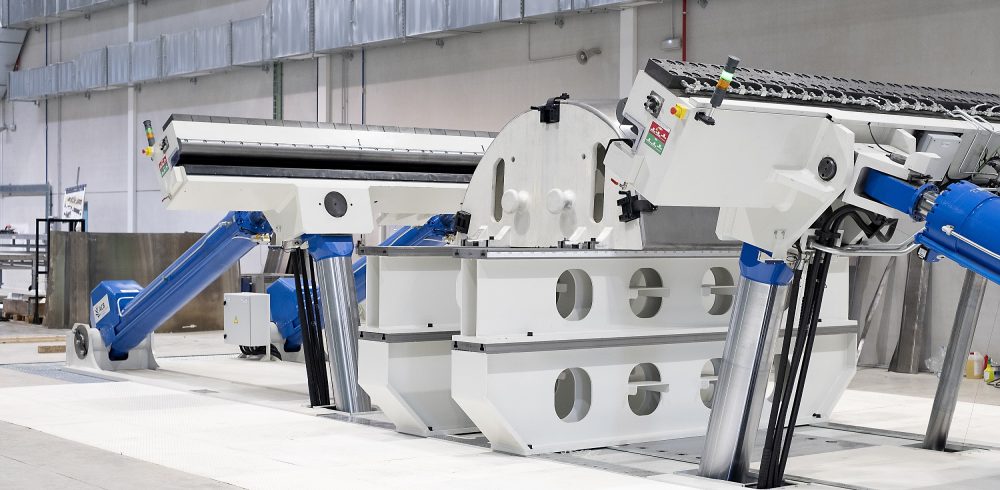

Concretely, Sofitec has incorporated into its technological fleet a stretch forming machine specially indicated for cold plastic deformation processes. This type of metalworking improves the properties of the treated material by exceeding its inherent elastic limit, making the final shape of the piece stronger (after even machining operations) and reducing the possibility of defects in its interior curvature. Also, the new equipment will allow the application of simple, complex curvatures and non-uniform geometries, thanks to its stretching force of up to 600 tons.

The company has also acquired, as part of this technological expansion, a 5-axis trimming machine of high performance and precision, with which it improves its capacity for the machining of large dimension elements, thanks to its mobile bridge system and aerial guidance.

It is expected that the new facilities under construction, annexed to the current ones, will be fully operational in the last quarter of 2019. With an area of 11,600 sqm -which will be added to the existing 38,000- will allow the company to increase its available capacity by 80%, in addition to raise its turnover.

Along with the mentioned areas, the expansion also includes the launch of an automatic baths line for anodizing of metallic materials, cleaning, and penetrant dye inspection; and a robotic painting line.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News