The aerospace industry’s resurgence, marked by renewed confidence and sales growth among the sector’s titans, heralds an era of opportunity for specialised suppliers that form the backbone of this complex ecosystem. From the commanding heights of Boeing and Airbus down to the precision engineering firms that supply them, the recovery narrative is broad-based and inclusive, offering fertile ground for the entire supply chain.

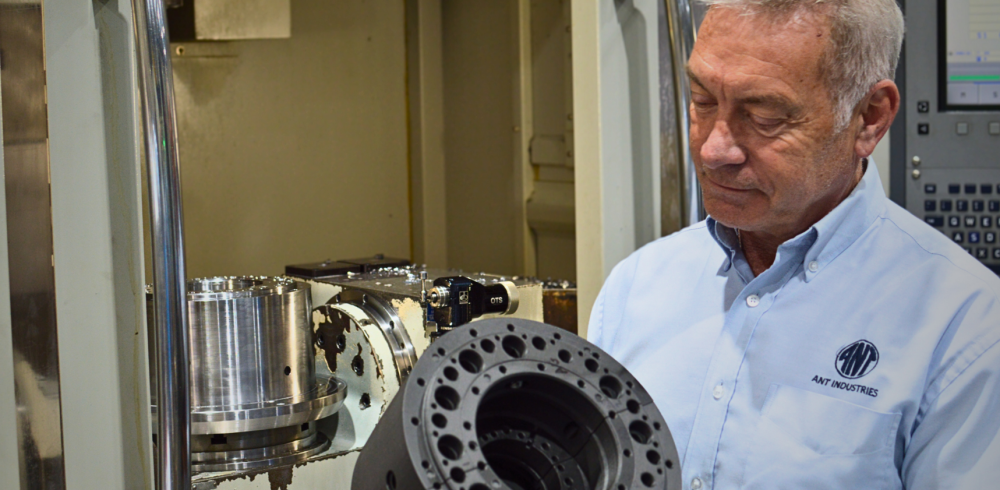

Shaun Rowley, Managing Director of ANT Industries, has every reason to view this resurgence with both optimism and strategic intent. His company, based in Atherstone, Warwickshire, has quietly built a reputation as a critical supplier of aerospace engine parts, and the signs of a broader industry recovery coincide with ANT Industries recording its largest ever order book, this has been achieved through lasting relationships built through stoic leadership, belief and multi-million pound investment in machining capability throughout 2023 and 2024.

As Rowley might assert, the demand uplift from aerospace primes like ITP, Rolls Royce and Siemens is vindication of ANT Industries’ long-term strategy. “For more than 45 years, the company has invested heavily in state-of-the-art precision engineering, enabling it to manufacture an extensive range of components and assemblies for more than 20 aerospace and gas turbine engines. This investment is now paying dividends as the industry’s big players, increasingly turn to reliable and innovative suppliers to meet their exacting demands” states Rowley.

Rowley’s perspective is grounded in the understanding that while companies like Airbus, ITP Aero and Rolls-Royce dominate the headlines with their massive revenues and high-profile aircraft programs, the success of such primes is intricately linked to the performance of suppliers like ANT Industries. “The aerospace supply chain is a finely tuned machine where every part, from the largest fuselage to the smallest engine component, plays a crucial role in ensuring operational success” says Rowley. The fact that Airbus continues to post strong figures, is a testament to the resilience and adaptability of this broader supply chain. “It is why we must continue to be at the forefront of technological change by driving an exciting and continual programme of investment in our capability through the business, such as our investment and application in additive layer manufacturing (ALM)” adds Rowley.

However, this resurgence is not without its challenges. The same supply chain issues that have plagued the industry’s giants—rising costs, late deliveries, and inflationary pressures—also ripple down to firms like ANT Industries. Yet, it is precisely in such a challenging environment that Rowley’s strategic foresight is most evident. By managing sub-tier processes, supply chain logistics, and program management with precision, ANT Industries must mitigate these pressures on behalf of its world class customers and strengthen its position as an indispensable partner to its clients.

Moreover, as the industry slowly returns to its pre-COVID performance levels in revenue terms, the role of mid-sized firms in sustaining this momentum cannot be overstated. The aerospace primes may drive the headlines, but the engines of growth—both literally and figuratively—are being crafted in the manufacturing floors of firms like ANT Industries. Rowley is proud of the firm’s capability being reflected in confidence in orders won; “With the company’s manufacturing facility equipped for turning, milling, grinding, and assembly operations, and a workforce that blends technical prowess with deep industry knowledge, we are well-positioned to capitalise on the growing demand from our prime customers” he continues. “We have continued to invest in state-of-the-art 5-axis CNC machinery and metrology capability to ensure our parts are fit for the fine safety critical parameters demanded by intricate aero-engine components which is being reciprocated with exciting, record breaking orders.”

In the broader context, ANT Industries’ record order book is a signal that the aerospace sector’s recovery is real, tangible, and widespread. As Rowley would likely emphasise, the company’s continued success is built on a foundation of quality, precision, and reliability—attributes that are increasingly sought after as the industry strives to return to full strength.

As aerospace primes navigate their recovery paths, the role of specialised suppliers like ANT Industries becomes ever more critical. Under Rowley’s leadership, ANT Industries is an active enabler, ensuring that as the giants rise, they do so on a foundation of uncompromised precision and quality. The firm’s recent 24 month NADCAP accreditation is demonstrating the firm is managing quality and inspection processes at the highest level. This synergy between primes and suppliers, bolstered by growing confidence and increasing orders, suggests that the aerospace industry’s best days may still lie ahead, with ANT Industries playing a pivotal role in that future. For more information please visit: www.antindustries.com or follow the company across its social media channels.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News