The first COTS-based robotic installation in the UK nuclear industry has been successfully completed, proving FANUC’s technology in this challenging field.

FANUC’s ARC Mate 120iC and M-900iB/360 robots have played a starring role in a pioneering waste size reduction project as part of Sellafield’s ongoing decommissioning process. In a first-of-its-kind autonomous application designed and delivered by integrator Cyan Tec, the skip sorting and laser cutting cell has reduced the amount of space needed to store radioactive waste to a third of its original footprint. The cell has also slashed the time it takes to dismantle and repack radioactive skips from months to minutes, whilst eliminating the need for human involvement in this hazardous operation.

Background: a major pond cleanup operation

First Generation Magnox Storage Ponds (FGMSP) – used to store and cool spent fuel from Magnox reactors before reprocessing – are now being decommissioned due to aging infrastructure and contamination. Over time, many of these ponds have become highly radioactive due to accumulated sludge, fuel debris and corrosion. Cleaning and decommissioning these ponds has therefore become a major part of Sellafield’s ongoing nuclear cleanup efforts.

To facilitate the cleaning and repair of these ponds, the skips that are stored in them need to be removed. However, the limited availability of storage space for the skips once they have been extracted presents a challenge. With a track record in building turnkey automation, laser and robotics solutions for the nuclear industry, Cyan Tec was called upon to devise a solution for a localised size reduction process that would minimise the storage footprint of the removed skips.

“The problem they faced was what to do with the skips once they had been removed from the ponds and emptied of their contents. The skips were no longer needed but because they were contaminated, they were required to be stored securely, and there is limited storage for this kind of waste. Our idea was to cut up the skips so they would occupy less space – in this way, three skips could effectively be reduced to one,” explained Tony Jones, Managing Director of Cyan Tec.

Previously, this type of work had always been performed manually, on the mistaken assumption that it was not possible to automate such a task. Operators wearing hazmat suits would use angle grinders to cut storage containers into pieces, but to limit exposure to radiation, they could only work for very short intervals. This meant that it would have taken approximately one month to break down each skip.

Fraught with challenges

However, automating this operation was no easy task, for a number of reasons.

Firstly, the cell needed to fit into a very small and defined area and, once operational, be completely autonomous, requiring no human intervention. This called for an extremely compact and reliable solution.

Secondly, the skips were all slightly different; whilst they were all welded fabrications, their dimensions and their construction varied, and Cyan Tec had no visibility on the range of these dimensional differences. Some of the skips had also suffered physical damage as a result of impact, poor handling or corrosion.

“Variability is always a challenge for an automated system that uses set cutting and handling routines,” noted Tony.

And thirdly, because of the considerations around safety and radioactivity, there were limited opportunities for commissioning and testing the system prior to installation.

A safe, efficient and space-saving solution

Cyan Tec designed and installed a full turnkey laser cutting and handling system to operate autonomously within a nuclear bunker. The system was designed and built at Cyan Tec’s Leicester facility and then installed at Sellafield and tested on non-radioactive skips before being put into action on contaminated skips under the supervision of project partner TKE Nuclear.

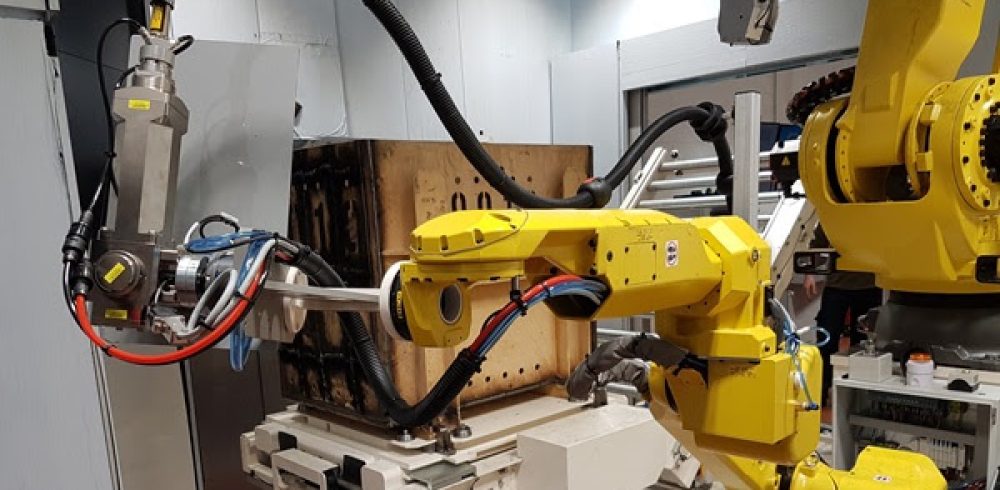

At the heart of the system are two six-axis FANUC robots: a compact ARC Mate 120iC for cutting, and a heavy duty M-900iB/360 for handling the panels. They were selected above all else for their world-renowned reliability, which has been proven in accelerated life tests and comes with an eight-year zero maintenance promise.

“The cell had to be 100% reliable, as there was no opportunity for going in and fixing it if anything went wrong. That was why we chose technology that had already been proven in demanding industries. FANUC’s robots are a great example of this; they have a strong track record of working in demanding automotive plants with very high uptime figures, and demonstrate the highest reliability of any robot manufacturer,” said Tony.

FANUC’s robots also aligned with Cyan Tec’s strategy of using commercially available technology wherever possible, as this was a test case for a COTS (Commercial Off The Shelf) project in an industry where an expensive bespoke approach has traditionally been the norm.

“There has always been this belief that robots used in the nuclear industry need special encoders in order to reliably provide positional feedback in the face of interference. We were ready to install external encoders onto these machines but in the end, we didn’t need to – the FANUC robots proved to be very robust in this environment,” said Tony.

The process explained

On entering the cell, the skip is transferred onto a servo-driven rotating table and presented to the system. The M-900iB picks up a scanning head and builds a 3D image of the skip within the machine’s control system. MeshLab software compares the scanned skip with a reference skip, enabling the control system to adjust the parameters of the ARC Mate 120iC robot (equipped with a laser cutting head) and determine the optimum cutting pattern. The camera also records the exact position of the output skip – important for accurate loading. The ARC Mate 120iC cuts the skip into pieces, leaving the structure intact for as long as possible to minimise the volume of debris in the atmosphere.

Next, the M-900iB robot places the scanning head in the tool changer and picks up an electromagnet instead. It then proceeds to remove each panel individually and pack them into the output skip. As the last panel (the base plate) tends to be coated with debris, it is hoovered before being placed in the skip.

This is the process for low level waste; a gamma camera in the cell checks the level of radiation on each plate prior to loading and if it detects a medium or high level, the robot transfers the panel onto a ‘toast rack’ for disposal via a different method.

The entire cell is operated remotely, from a control room 100 metres away from the bunker.

According to Cyan Tec, the M-900iB’s combination of reach, payload and compact dimensions was vital to the success of this installation.

“We needed a robot that could reach all the way to both skips and was physically strong enough, but we didn’t want a big robot because the entire build had to fit within a guard system for damage limitation in the event of a fault with the laser. With its 360kg payload capacity and 2,655mm reach, the FANUC M-900 provided the large work envelope we needed,” said Tony.

Results: from one month to one hour

The robotic cell was originally designed to size-reduce 50 skips of nuclear waste. It was so successful that it has since been used to process further skips of waste in a fraction of the time and with none of the health & safety implications of a manual operation.

“This system has revolutionised the handling and size reduction of skips and demonstrated that a COTS approach can work in the nuclear industry,” said Tony.

He continued: “It is incredible to think that by automating this task, we have been able to reduce the time it takes to cut down and repack a skip of waste from approximately one month to just 60 minutes. The efficiencies this brings are huge, but what really makes this project stand out is its health & safety impact as it eliminates exposure as a risk factor altogether.

“FANUC’s technology has been pivotal in achieving this outcome and our confidence in the solution we have delivered is rooted in our confidence in FANUC’s reliability and support.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News