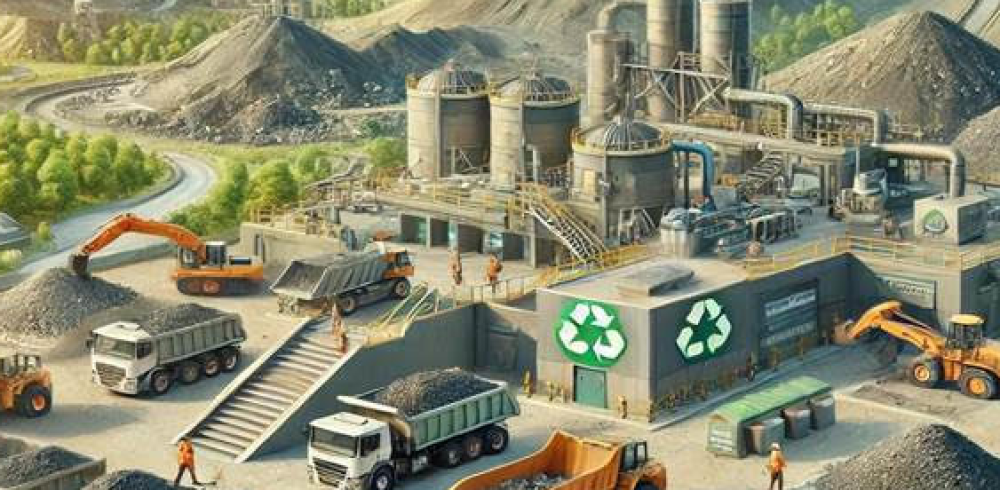

Mining is a cornerstone of the global economy, providing vital raw materials for industries ranging from construction to technology. However, it also has significant environmental impacts, especially in terms of waste production. As the world pushes toward more sustainable practices, mining companies are increasingly recognising that effective waste management is not only a regulatory requirement but also an opportunity to enhance their profitability and contribute to environmental conservation. In this blog, we’ll explore how mining waste management is transforming the industry, driving both environmental sustainability and economic growth.

Understanding Mining Waste: The Environmental Challenge

Mining operations generate various types of waste, including overburden (soil and rock removed to access minerals), tailings (residual waste left after extracting valuable materials), and waste rock (non-valuable rock left after extraction). These waste materials, if not properly managed, can lead to significant environmental damage, such as soil degradation, water contamination, and habitat destruction.

One of the most concerning aspects of mining waste is the long-term impact it can have on local ecosystems. For example, tailings from metal mining may contain hazardous substances like heavy metals, which can seep into nearby water sources and harm aquatic life. Improper disposal of mining waste can also contribute to air pollution, soil erosion, and deforestation.

Historically, mining waste has often been discarded in large, unmanaged dumps or tailing ponds. However, as environmental regulations have tightened and public awareness of the industry’s ecological impact has increased, the mining sector has begun to innovate and improve its waste management practices.

Why Mining Waste Management Matters: Environmental and Economic Benefits

Efficient mining waste management is crucial for reducing the ecological footprint of mining operations and ensuring that valuable resources are not wasted. Effective waste management systems can mitigate environmental risks, lower operational costs, and help companies comply with stringent regulations. Additionally, they present opportunities for economic benefits that go beyond regulatory compliance, including improved efficiency, reduced waste disposal costs, and the potential for valuable resource recovery.

1. Minimizing Environmental Impact

Improved mining waste management brings significant environmental benefits, primarily by reducing negative impacts on the surrounding ecosystem. By adopting responsible waste disposal practices, mining companies can decrease soil contamination, water pollution, and air emissions. Proper management of tailings and other waste materials also prevents toxic chemicals from leaching into the environment, safeguarding local wildlife and nearby communities.

The global mining waste management market is projected to reach a value of US$307.53 billion by 2031, up from US$197.9 billion in 2024. This growth is expected to be driven by a compound annual growth rate (CAGR) of 6.5% between 2024 and 2031, according to a report by Persistence Market Research.

For instance, many mining companies are now using lined tailings storage facilities that prevent waste from leaching into groundwater. Other methods, such as dry stacking, allow tailings to be compacted and stored in a dry, stable form, reducing the risk of contamination. Additionally, progressive rehabilitation practices, including replanting vegetation and restoring ecosystems, can help rehabilitate mining sites once operations have ceased.

2. Resource Recovery and Waste-to-Value Opportunities

Another key aspect of mining waste management is the potential for resource recovery. In many cases, mining waste contains valuable materials that can be extracted and reused, which not only reduces waste but also generates additional revenue for mining companies.

For example, the mining process often leaves behind precious metals or minerals that are too low in concentration to be economically extracted during the initial operation. However, with the advancement of technology, companies can now extract these residual materials through processes like flotation or chemical leaching. This concept, known as “mine tailings reprocessing,” has become an increasingly profitable venture.

In some cases, even the waste material itself can be converted into a valuable resource. For example, waste rock from mining operations can be used in construction projects as aggregate, reducing the need for virgin materials and saving costs. Similarly, mining companies have begun exploring ways to use waste materials for energy production, such as converting biomass waste into bioenergy.

3. Cost Savings and Profitability

Proper waste management can directly impact a mining company’s bottom line by reducing operational costs. Poor waste handling and disposal can result in hefty fines, lawsuits, and cleanup costs, which can significantly eat into profits. By investing in effective waste management practices, mining companies can avoid these financial burdens and improve their overall profitability.

One of the ways companies are saving money is by reducing the amount of waste sent to landfills or disposal sites. With technologies like waste segregation and recycling systems, mining companies can divert large amounts of waste from traditional disposal routes, leading to significant cost savings. Moreover, implementing more efficient waste management systems can also streamline operations and reduce energy consumption, further driving down costs.

Additionally, mining waste management can lead to significant tax incentives and credits, as many governments around the world offer financial rewards for businesses that demonstrate a commitment to sustainable practices. This can further incentivize mining companies to adopt greener waste management strategies.

Innovative Mining Waste Management Solutions

The mining industry is rapidly embracing innovative technologies and practices to address the challenges of waste management. Here are some cutting-edge solutions that are helping companies reduce their environmental footprint while boosting their financial performance:

1. Tailings Reprocessing and Recycling

As mentioned earlier, many mining operations leave behind valuable minerals and metals in their tailings. With advancements in technology, mining companies can now extract additional value from these materials, reducing waste and improving the economics of mining operations. Tailings reprocessing is becoming a significant part of the mining industry, with companies investing in new technologies to recover metals like gold, silver, and copper from waste materials.

This reprocessing not only generates revenue but also reduces the environmental risks associated with storing large volumes of tailings in tailing ponds. In some cases, it can even help eliminate the need for extensive tailing storage facilities, reducing land use and associated costs.

2. Dry Stacking of Tailings

One of the most promising techniques for managing mining waste is dry stacking, which involves dewatering tailings and stacking them in a dry form. This method is particularly useful for industries like gold and copper mining, where the waste material is more stable when stored in a dry, solid form. Dry stacking eliminates the need for traditional tailing ponds and their associated risks, such as the potential for tailings dam failures and toxic leaks.

The benefits of dry stacking are significant. It reduces the environmental footprint of mining operations by reducing water usage and minimizing the risk of pollution. It also makes it easier to reclaim and rehabilitate mined land once operations have finished.

3. Waste-to-Energy Solutions

Mining companies are increasingly looking to convert waste materials into energy. This process, known as waste-to-energy (WTE), involves using mining waste like biomass or organic material to generate electricity or heat. WTE systems can be integrated into mining operations to provide a sustainable source of power, reducing reliance on fossil fuels.

Moreover, WTE helps reduce the volume of waste sent to landfills and provides a more sustainable energy solution for mining operations, which are often energy-intensive. By adopting WTE technologies, mining companies can reduce their environmental impact while improving their operational efficiency.

4. Bioremediation and Phytoremediation

In cases where mining waste has caused soil or water contamination, bioremediation and phytoremediation offer eco-friendly solutions. These techniques involve using microorganisms or plants to absorb or break down contaminants, making the environment safer and more stable.

Bioremediation uses bacteria or fungi to break down hazardous chemicals in mining waste, converting them into less harmful substances. Phytoremediation, on the other hand, involves planting certain types of plants that can absorb heavy metals and other pollutants from the soil, restoring the ecosystem to its original state.

Conclusion: A Win-Win for the Environment and the Industry

Mining waste management is no longer just about meeting regulations and mitigating environmental impact—it’s a vital part of the industry’s drive toward sustainability and profitability. By adopting innovative waste management practices like resource recovery, dry stacking, and waste-to-energy solutions, mining companies can not only reduce their environmental footprint but also boost their bottom line.

With the right strategies in place, mining can be a more sustainable industry that contributes to environmental conservation while supporting global economies. As public awareness increases and technology advances, mining waste management will continue to evolve, transforming the industry and helping pave the way for a greener, more responsible future.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News