Spares and consumables as the first defence against downtime

In our experience, the main cause for downtime in abrasive blasting, is a gradual decline in performance, not immediate failure, so you are chasing inconsistent profile, rework, visibility issues and stoppages. This frequently feels “sudden” because the warning signs were missed.

The fastest route to higher throughput is not a new blast pot or a bigger compressor. It is treating three areas as planned maintenance:

- The flow path

- The visibility path

- The control and compliance path

All backed by a spares plan built around measurable triggers.

Read about where you lose performance, what to watch, and what to keep on the shelf so your production rate and audit evidence do not depend on urgent orders.

1) The flow path: if air and abrasive flow drift, everything slows down

Nozzles: small wear, big losses

Nozzle wear is one of the most common ways a blast line silently loses capacity. As the bore opens up, air demand rises while nozzle pressure and media velocity fall, so cleaning slows and media use creeps up. The result is longer cycle times, inconsistent finish, and operators compensating with dwell time.

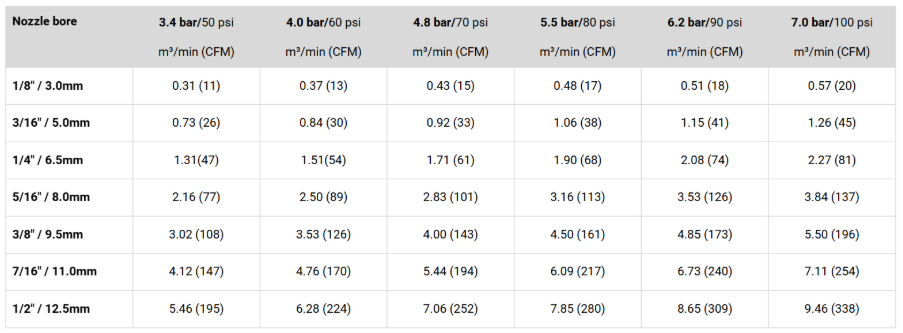

The practical fix is to treat the nozzle as a gauged component, not a “use until it fails” part. Air consumption tables make the relationship between nozzle bore, pressure and cfm clear, so you can check whether the compressor still has headroom at your working pressure.

What to do

- Gauge weekly (or in line with duty cycle) and log the bore.

- If you are edging beyond compressor capacity, do not just turn up pressure, confirm the nozzle-to-compressor match using your air consumption table.

- Replace the nozzle when bore growth pushes you into unstable blasting, pressure drop, or unacceptable cycle-time creep.

Hoses and couplings: choking the system is easy to miss

Even with a good nozzle, undersized hoses, tired couplings, leaks and worn gaskets restrict flow. Symptoms include slower cutting, pressure drop at the nozzle, and inconsistency that is difficult to diagnose on the shop floor.

What to do

- Match hose and coupling IDs to the nozzle and application.

- Replace worn sections and gaskets early, then verify seals and continuity end-to-end, especially where bonded hose systems are used.

A simple fault-to-fix map

- Slower blasting, more media used → likely nozzle wear → gauge bore, replace, re-check air demand.

- Pressure drop at the nozzle → hose ID too small, leaks, tired couplings → fit correctly sized hose and couplings, replace gaskets, re-test.

- Profile drift and rework rising → nozzle wear or pressure instability → replace nozzle, confirm compressor/nozzle pairing and working pressure.

2) The visibility path: productivity often fails at the operator’s face

When production managers talk about downtime, they often mean “the line stopped”. Operators experience a broader truth, fogged lenses, slow lens changes, poor airflow, heat stress and uncomfortable PPE all reduce effective blasting time, even when the line is technically running.

Lens systems: reduce stop-start working

Lens change is a small task that repeats constantly. Systems designed around fast replacement and consistent sealing reduce interruptions and support steadier pace, particularly where dust load and rebound are high.

What to do

- Standardise a lens replacement and keep the packs on the shelf.

- Put seals, gaskets and padding on a refresh schedule.

Comfort is not a “nice to have” on long shifts

If a blast suit or helmet is uncomfortable, people take breaks earlier, move differently, and work more slowly. PPE designed for mobility, temperature regulation and durability supports consistent output, especially on long or demanding jobs.

3) The control and compliance path: evidence is part of the job

In many plants, compliance documentation is treated like admin. In practice, it is operational insurance. If you cannot evidence control, you create audit risk and disruption at the worst possible time.

Breathing air testing: schedule it, record it, retrieve it fast

Breathing air checks should run on a defined cadence, with documentation stored where it can be retrieved quickly.

What to do

- Build a 3-month cadence for breathing air testing and filter element checks.

- Log date, compressor ID, location, results, remedial actions, and sign-off.

- Store certificates so they are easy to find for audits and investigations.

Dust control: manage filter condition with measurement, not guesswork

Dust extraction issues show up as poor visibility, fogging, and ineffective capture. The operational fix is straightforward, but only if extraction components and seals are treated as planned replacements.

Five “replace it now” checks for maintenance teams

- Nozzle gauge fails (bore growth beyond expected)

Replace the nozzle, then re-check air demand and working pressure against your air consumption table. - Lens changes are slow, seals are tired, visibility degrades fast

Replace lens consumables, refresh seals and padding, standardise the replacement approach. - Hose soft spots, cuts, leaks, tired gaskets, or continuity concerns

Replace affected sections and gaskets, then verify end-to-end. - Breathing air filter elements overdue, uncertainty about air quality evidence

Replace cartridges and complete breathing air testing on schedule, retain records. - Dust capture struggling, visibility poor, extraction performance inconsistent

Replace cartridges and seals, inspect the system, restore baseline performance.

What to keep on the shelf: a practical spares plan in three paths

Flow path (speed and profile stability)

- Venturi blast nozzles matched by bore size and application

- Retainers, gaskets and key seals

- Blast hose sections, couplings and clamp sets sized to your standard set-up

Operator path (visibility and pace)

- Helmet lens consumables and window gaskets

- Cape and attachment components as required

- Blast suits and PPE items sized and rotated for actual shift demand

Control and compliance path (evidence and reliability)

- Breathing air filters and replacement cartridges

- Key gauges, regulators and control components used on your set-up

Treat consumables as a reliability system

Stop thinking of consumables as “small parts”. They are the control points for airflow, profile consistency, operator effectiveness and audit readiness. Define what good looks like, measure drift early, then replace on triggers, not failure.

Find out more at www.surfaceprep.com

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News