From September 10 to 14, 2024, the metalworking industry will once again descend on the Messe Stuttgart exhibition centre as the AMB opens its doors. WFL will be live on site once again with a stand and two MILLTURNs, the M20-G MILLTURN / 1500mm and the M50 MILLTURN / 3000mm.

The M20-G MILLTURN appeals to customer segments that are looking for a compact and powerful complete machining centre. With the addition of two further centre distance versions, with 2000 mm or 3000 mm, the new M20 MILLTURN will soon also be available for longer shaft parts. Special features include the high stability of the machine as well as the holistic motor spindle concept for demanding machining technologies.

Visitors to the trade fair in Stuttgart will be able to watch a technologically challenging chuck part for the aviation industry being machined live. The workpiece has a length of 150 mm and a diameter of 300 mm.

On the M50 MILLTURN / 3000mm, WFL will provide a live demonstration of the machining of a power generation shaft, as well as turbine blades and fir tree and generator shaft profiles. The demonstration workpiece has a diameter of 600 mm and a length of 2355 mm.

A focus on machining chuck parts

At the AMB in Stuttgart, visitors can also check out an exhibit on the Quick Change System. This automatic system is an innovative WFL solution for horizontal complete machining of chuck parts. It is based on a high-precision, fully variable clamping system. Clamping tools, such as pallets, power chucks, clamping mandrels and, if required, face drivers, can be changed over fully automatically between the machine, clamping device and interim storage, to suit requirements. With this solution, the process for clamping and aligning the workpiece on the clamping pallet takes place on a vertical external clamping table or a set-up station. The set-up station comes in the form of a stable short taper mount with high repeat accuracy and is equipped with an identical interface to that on the headstock. The clamping tools including the workpiece can be changed over automatically. Alternatively, when using power chucks, the workpieces can be changed directly in the chuck with the aid of a robot and the workpieces can be transferred to the counter spindle so that complete 6-side machining can be carried out. The advantages of quick and, above all, precise exchange of equipment, including the workpiece, in the machine will be demonstrated using the M80 MILLTURN as an example.

Mobile robot automation with the mobileCELL

The demonstration of a mobile robot installed on an automated guided vehicle (AGV) is set to be one of the highlights at the WFL stand. It will show how it picks up chuck parts and tools from the warehouse and deposits them on the AGV. The mobile robot will then travel to the machine and, using a camera, scan the QR code to determine its exact position. The workpiece and tool are loaded and then removed again. For tools, there is an HSK-63 gripper and a Baruffaldi tool turret with EPPINGER QUICKLOCK tool holder system for automatic tool changes on the tool turret.

Mobile robots do not need cables or human input. Another key advantage of these robots is that they avoid obstacles, meaning that they can also be used in halls where the set-up is constantly changing and where machines and people are moving around. Sensors help to ensure that mobile robots move safely and efficiently between locations and interact safely and efficiently with people, forklifts and other material handling equipment.

Using intelligent software in combination with the relevant automation solutions not only enables workpieces to be loaded and unloaded but also means that machining centres can be supplied fully automatically with tools and clamping devices. As an innovative automation partner to WFL, FRAI is presenting its mobile robot system “mobileCELL”, which responds to this trend, at the event. This concept has scope for various expansion stages, making it as future-proof as possible. See what these robots can do for yourself at AMB in Stuttgart!

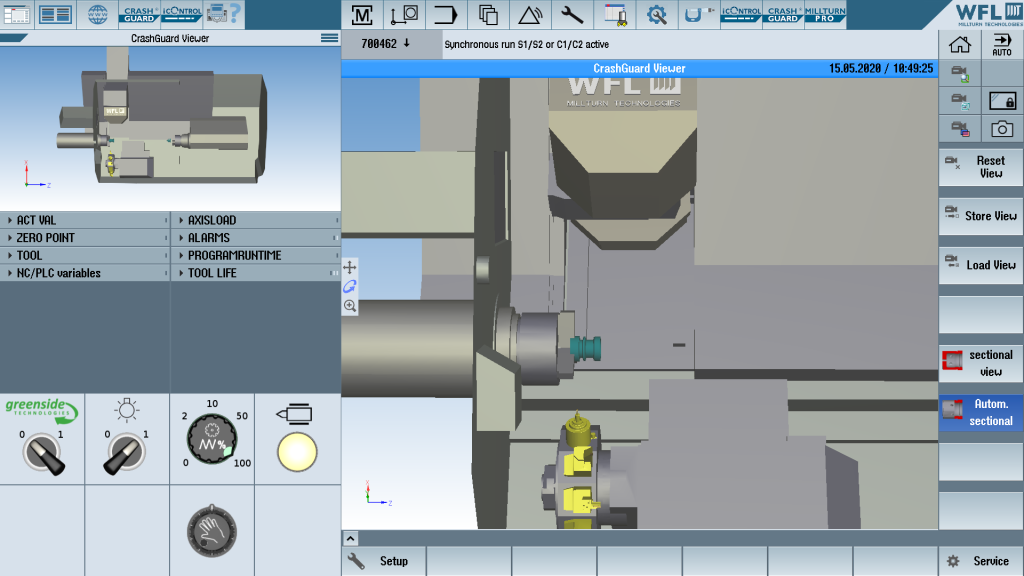

Collision prevention with CrashGuard Studio

WFL is continuously optimising the machining processes on its machines. However, there are always interruptions where the operator needs to intervene to carry out checks and measurements, for example. It is important to keep these interruptions to a minimum to optimise the availability and productivity of the machine. WFL is using its decades of experience to offer well-engineered software solutions relating to the manufacturing process with a MILLTURN. One of these tools is the CrashGuard Studio, which will also be showcased at the AMB in Stuttgart.

The realistic 3D simulation software CrashGuard Studio is the ideal tool for testing and optimising CNC programs after creation or modification. These tests can be carried out at an external work station or directly on the machine control system. Optimising the entire machining process and ensuring faults are corrected early significantly reduces the risk of collisions and generation of scrap, while also doing away with unproductive run-in and run-out times.

This opens up new performance potential, creating a considerable competitive advantage. CrashGuard Studio is the perfect addition to any CAD/CAM software, as well as to the WFL collision prevention software CrashGuard. The data for workpieces, tools and clamping devices can be transferred as required.

The interactive graphics of the Millturn PRO programming editor enable NC programs to be created efficiently and easily, making CrashGuard Studio a universal programming system for complex workpieces (without freeform surfaces). Programming can be carried out at an external programming station or directly on the machine’s operator control panel. The programmed machining operations can be reviewed continuously and step by step in CrashGuard Studio.

The technology cycles from WFL cover an extremely broad range of standard and special technologies for all conceivable applications. These program modules, which only require the input of parameters, make it possible to carry out efficient programming directly on the machine control or on a PC. A program can therefore be created for both complex and simple workpieces in only a short period of time.

WFL offers the appropriate technological solution for every type of gear cutting task – from filigree internal gears with high accuracy requirements to large external gears that require strong roughing performance.

Operational data acquisition with myWFL

The myWFL product range consists of the operational data acquisition software myWFL Cockpit, the multifunctional energy optimisation tool myWFL Energy, the myWFL Condition Monitoring System and the myWFL Health Check. Machine and program states over time, productivity and technical availability will all be displayed, either on the machine control system, PC or mobile device via a web browser. This means that the user can always be well-informed about their machine productivity.

myWFL Reporting is a new feature. With this software, users can automatically create reports and events for trigger types programmed manually or in a time-controlled or programme-controlled way. The myWFL E-Mail Messenger is currently under development.

Come and see our latest innovations on our stand – Stand 6A11 in Hall 6.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News