In the fast-paced world of industrial technology, staying ahead of the curve is essential. Futureproofing your equipment can help to ensure your operations remain up to date, but how do you achieve this? Here, Ross Turnbull, Director of Business Development and Product Engineering at ASIC design and supply company Swindon Silicon Systems, explains how an ASIC can enable futureproofed design.

Thanks to increased digitalisation and evolving customer demands, the manufacturing industry has undergone significant changes in the last few years. But keeping up with such a rapid pace of change isn’t easy, especially within the industrial setting. Industrial equipment is typically expected to offer a long service lifetime, retaining functionality and efficiency throughout. And high upfront costs of new machinery mean that frequent replacement is not viable. Neither is the disruption that would be caused to production processes by removing or installing new equipment.

So how can you ensure machinery will continue to offer high performance for years to come, particularly when it’s not something that is simple to upgrade or replace?

Exploring industrial sensors

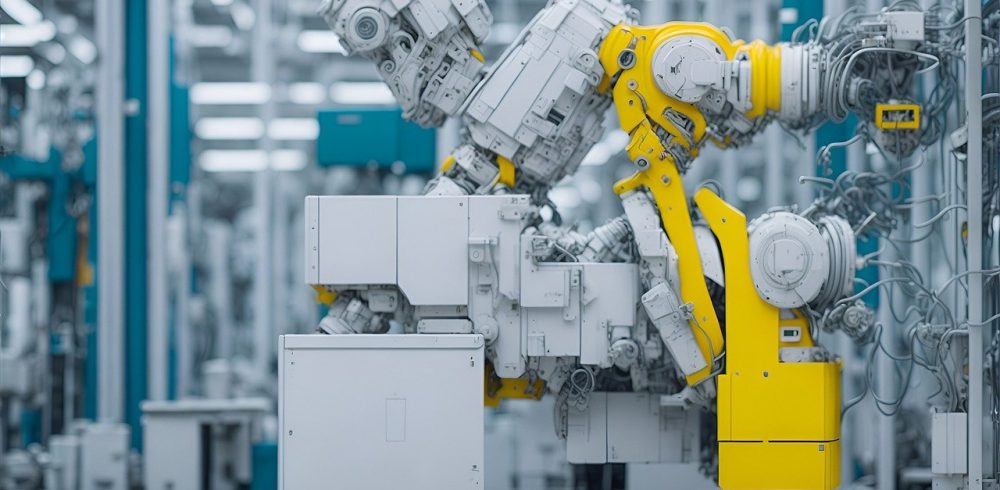

To understand how we can futureproof industrial systems, we’ll need to explore these devices in a bit more detail. Automation technologies, often found in today’s manufacturing plants, will typically rely on a variety of sensors to ensure smooth operation. Assembly robots and pick-and-place machinery, for example, will use position sensors to ensure accurate movement. Quality assurance processes often feature optical sensors to carry out automated visual inspections. These sensors are crucial in providing the necessary sensing and feedback information for machinery to work as intended.

To help improve the quality of these sensors and the data they can collect, we can take a closer look at the sensor interface. This is the bridge between the sensing element and the main device, responsible for converting the input analogue signal into a suitable output signal.

Standard integrated circuits (ICs) may be used as the sensor interface. But for industrial systems with a competitive edge, offering better precision and performance, there’s another solution available.

Enhanced electronics

This takes the form of an Application Specific IC (ASIC). An ASIC is a custom chip designed to fit the specific needs of the application, ensuring superior performance and efficiency over a standard IC.

In the context of industrial systems, ASICs offer several advantages. Enhanced performance means that even as customer demands change and product requirements develop, the sensing capabilities of the device are still more than sufficient to complete the required function. Bespoke construction means they are designed to last for as long as the machinery requires, with no loss of measurement or signal accuracy. Ultra-low power consumption means that this is possible even for battery-operated sensors.

Furthermore, any unnecessary components can be removed for a streamlined design. Not only does this facilitate greater investment in performance when it truly matters, but the reduction of parts also means a more robust sensor. This increased resistance to harsh external conditions — such as strong vibrations — is an essential for operation in heavy-duty industrial environments and helps to guarantee a long lifetime.

The ASIC route also helps to guarantee future IC supply. While standard IC production can be halted at any time at the manufacturer’s discretion, it’s different with an ASIC. Here, the approach is much more proactive in providing a consistent chip supply, alleviating manufacturer concerns.

As the industry continues to undergo rapid development, there’s an ever-growing pressure for manufacturers to keep up. But where it isn’t feasible to continuously be swapping out equipment, there are ways you can enhance your product without a complete overhaul. Here, custom ICs are essential, offering high performance, tailored solutions to provide the market advantage.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News