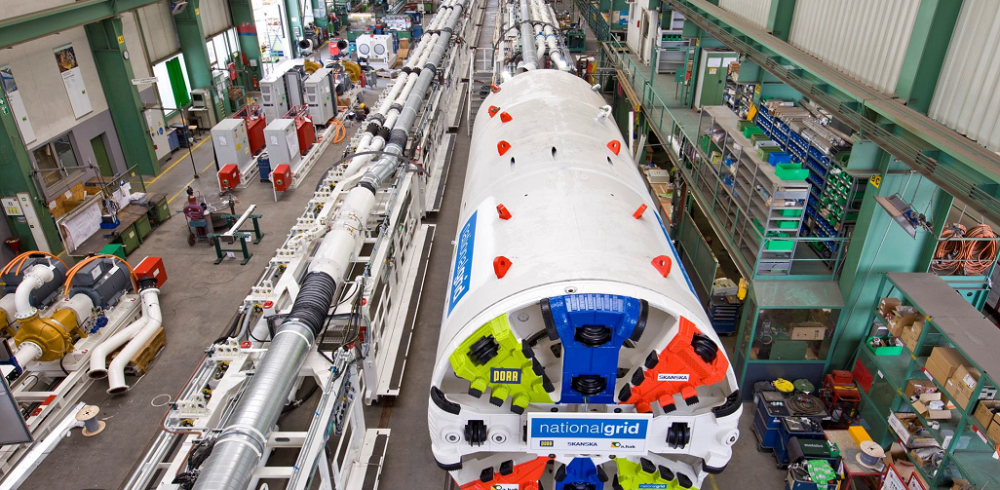

The National Grid has announced that they are gearing up to start their dig underneath the depths of the river Humber. The National Grid, one of the largest investor-owned energy companies in the world have been preparing to start the project, and the 160 meter boring machine that will be utilised for this work will soon be delivered to site.

This huge tunnel boring machine is expected to arrive on the site at Goxhill, which is near to Hull at some point on either the 5th or 6th December. The components for this enormous machine are expected to arrive over the two days, and the machine will be put to work excavating a 5 km tunnel under the River Humber in order to carry a replacement gas pipeline. While the parts for the boring machine are being delivered, motorists are being advised to expect some delays on local roads, as there will be slow moving deliveries made from Immingham Docks.

After the machine has been put together, the five kilometer dig is expected to take a year to complete and will travel under the river and then emerge on the north bank at Paull. This project will create a 3.65-meter diameter tunnel that travels 35 meters below the river bed. Once this tunnel has been completed, a new 42-inch diameter gas pipeline will be installed as a replacement to an existing one. This current pipeline crosses the river and has been laid in a trench just below the riverbed. Because of its position, the pipeline is at risk of being exposed when the tides changed. This Humber Pipeline Replacement project offers a long-term solution to the position of this pipeline.

The National Grid has awarded the contract to build the tunnel to a joint venture that has been submitted by Skanska, PORR Bau GMBH and A. Hak. The contract has a value of £100 million. The boring machine that has been manufactured in order to carry out this work, has been created in Baden-Wurttemberg in Germany, disassembled and shipped to Goxhill, near Hull. The parts will travel via Rotterdam on the road, before being shipped to Immingham Docks and transported, again by road to the Goxhill site.