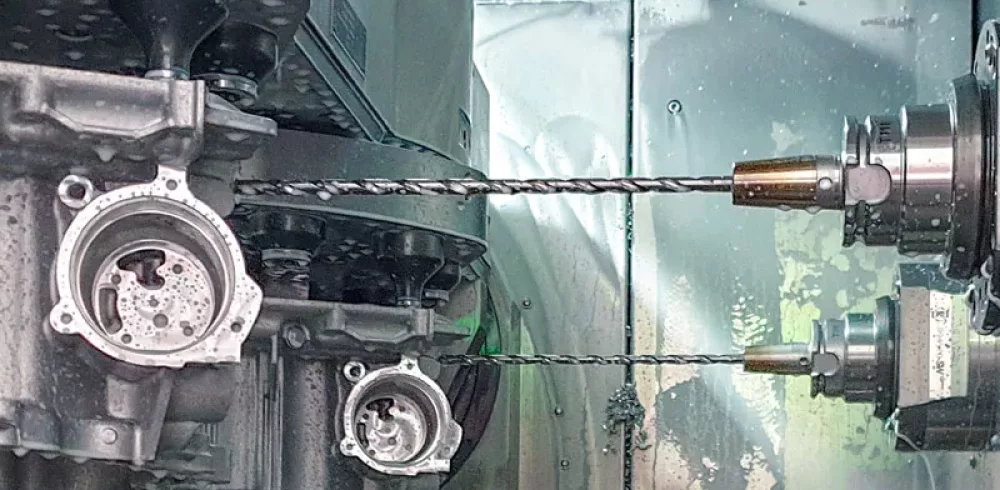

MEGA-Deep-Drill-Steel Tip for depth

With the MEGA-Deep-Drill-Steel, MAPAL showcases the new standard for deep drilling at the EMO, which has been specially designed for machining steel and cast iron.

The solid carbide deep drills are optimally protected with an innovative coating with HiPIMS technology in the cutting edge area. The head coating also ensures frictionless chip removal and is therefore the prerequisite for the reliable production of deep bores. The remaining length of the MEGA-Deep-Drill-Steel remains uncoated. “In our opinion, there is nothing smoother than a polished solid carbide surface”, Michael Villwock, Product Manager for Solid Carbide Tools, reaffirms the approach.

Spherical cutting edges provide a high level of stability and thus ensure a long tool life and high level of productivity. The point angles were selected so that the deep drills always start the cut with the chisel in the pilot bore. The standard range available from stock includes length ratios of 15xD to 40xD and the diameter range from 3 mm to 16 mm, with the long designs up to 9 mm. Adapted pilot drills are available for difficult drilling conditions.

With the MEGA-Deep-Drill-Steel, deep drilling is possible without pecking cycles at very high feed rates. The tools are suitable both for use with internal cooling and for minimum quantity lubrication, which has a positive effect on the tool life in steel machining. Field tests have shown that the new deep drills from MAPAL meet the highest requirements for tool life and performance even with demanding materials. Compared to its predecessors, up to 50 percent higher feed rates can be achieved.

Short profile MAPAL Dr. Kress KG MAPAL – tooling the customer’s success

MAPAL Präzisionswerkzeuge Dr. Kress KG is one of the leading international suppliers of precision tools for the machining of practically all materials. The company founded in 1950 supplies leading customers from the automotive and aerospace industries and from machine and plant engineering. With its innovations the family-owned company sets trends and standards in production and machining technology. MAPAL sees itself as a technology partner, supporting its customers with the development of efficient and resource-conserving machining processes using individual tool concepts. The company is represented with production facilities, sales subsidiaries and representatives in 44 countries worldwide. The MAPAL Group generated sales of EUR 558 million in 2022 and has around 5,000 employees.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News