Additive manufacturing is being used in an innovative way at a hospital trust in Bristol, UK, allowing clinicians to deliver a streamlined treatment for babies suffering from flat head syndrome. The project has involved the 3D printing of highly bespoke polymer helmets that help to reshape young skulls over time.

Flat head syndrome, also known as plagiocephaly or brachycephaly, is caused by pressure on a baby’s skull, which often comes from sleeping in the same position. This means the head sometimes flattens in one spot. According to the UK National Childbirth Trust, as many as one in five babies get some sort of flat head syndrome at some point, and most get better without any treatment. However, in more severe cases, correctional action can be required.

How North Bristol NHS Trust Hospital and Stratasys are shaping the future of medical 3D printing

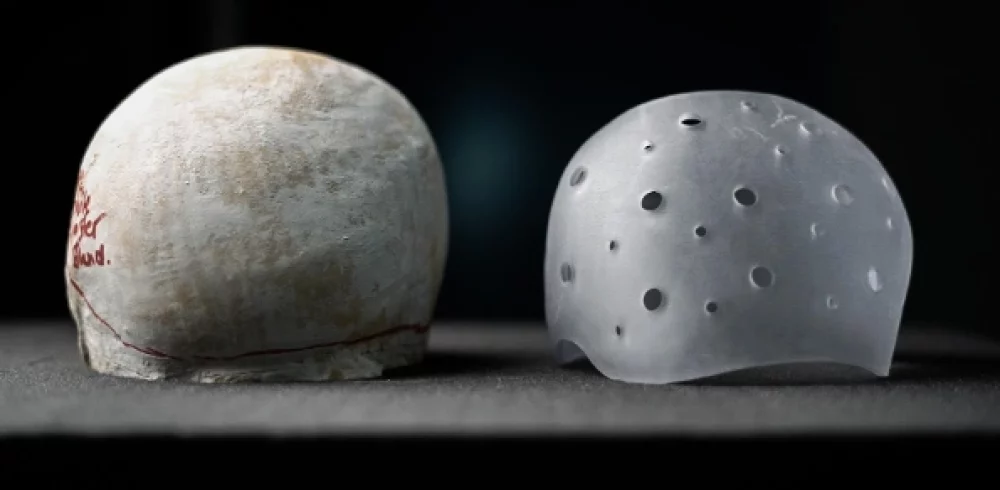

At Bristol Helmet Service in North Bristol NHS Trust, reconstructive scientists are deploying additive manufacturing technology to print highly customised helmets that relieve the pressure during head-resting to help reshape a baby’s skull as it grows. The helmets are created from digital scans of a baby’s head using a Stratasys J5 printer. The machine builds up layer upon layer of biocompatible Med610 resin with extreme precision, ensuring every helmet produced is the perfect fit.

“Additive manufacturing is the ideal technology for this application,” says Erez Ben Zvi, VP Healthcare, Stratasys. “The J5 offers unmatched accuracy, empowering medical teams to create patient-specific models on demand. It is also compact, with intuitive software, making it the perfect solution for point-of-care facilities such as hospitals and clinics. The machine can also be used to create biomechanically accurate, highly realistic anatomical models – so there are opportunities to expand its use elsewhere.”

The Stratasys J5 was supplied by Tri-Tech 3D, a Stratasys platinum partner that offers a variety of 3D printing technologies, including Fused Deposition Modelling, Polyjet, Stereolithography, and Selective Absorption Fusion. Tri-Tech 3D worked closely with North Bristol NHS Trust to ensure it selected the most suitable printer for its needs. It then helped oversee installation and training so that the reconstructive prosthetics team could get maximum performance from every print.

“North Bristol NHS Trust had a real vision for additive manufacturing technology and built a rock-solid business case,” says David Moore, 3D Print Consultant at Tri-Tech 3D. “From there, we worked together closely to ensure that the J5 met all technical specifications and performance criteria while advising on many other factors such as specific configurations, materials and maintenance.”

Beyond the cradle: The expanding horizons of additive manufacturing in healthcare

North Bristol NHS Trust Bristol Helmet Service is currently the only hospital service in the UK that provides 3D-printed helmets on the NHS, and the Bristol team is leading studies to improve parents’ awareness and supply guidance for other clinical teams considering similar approaches.

“We have recently developed this streamlined digital process, which has now replaced the physical moulding and stone plaster replicas of the babies’ heads that was previously our only option,” says Amy Davey, Lead Reconstructive Scientist, at the Bristol Helmet Service, North Bristol NHS Trust. “This has only been possible through 3D scanning and the J5 printer, which enables a completely digital process, allowing us to design the helmets on-screen, print them in biocompatible resin and very little post-processing to finish.

“It has made the treatment process much quicker for patients and time-efficient for us, enabling us to assess and treat more patients for this condition. We are now developing techniques in other treatment processes to provide streamlined options for other specialities in our trust.”

Sally Bennett, Director of Southmead Hospital Charity, which helped fund the additive manufacturing equipment, adds: “We are thrilled that we have secured funding for the equipment within the centre and are delighted that it will have a large impact on patient experience.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News