GKN Powder Metallurgy (GKN PM), a global leader in powder metallurgy and provider of advanced filtration solutions, announces the introduction of its new Metallic Membrane cartridge filters. Designed to meet the growing demand for fine filtration in the chemical, pharmaceutical and food and beverage industries, this product offers significant improvements in filtration performance, efficiency, and sustainability.

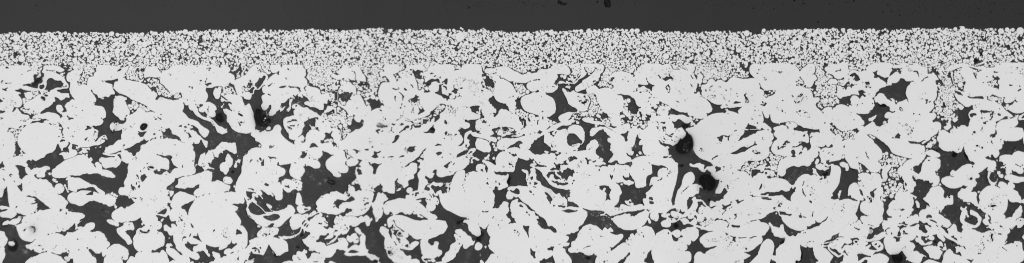

Innovation in the powder metallurgy industry, particularly around metal attribution for specific applications, evolves alongside the shifting demands of the market. Utilizing two decades worth of experience with this technology and initially developed for outside coating by GKN PM, the company now also places the metallic membrane on the inside of the filter element. The inclusion of the metallic membrane on the inside offers improvements including:

- Superior cake release

- Reduced downtimes

- Increased flow rates

This development of the design leads to up to 30% higher productivity compared to conventional filters. In addition, GKN PM’s seamless filters are available up to 72-inch in length which provides superior mechanical strength over other conventional solutions on the market, such as welded designs. Longer elements will be produced by adding a single radial welding seam.

“With the launch of our new metallic membrane cartridge filters, we are aiming to bridge the gap in reliability and sustainability when it comes to filtration systems,” said Dr. Harald Balzer, Head of Product Engineering/Filters. “This solution is designed to deliver better performance, reduce operational costs, all while ensuring our customers receive localized technical support, whether they’re operating in the US, Europe, or elsewhere around the world.”

The filters are primarily used in chemical and pharmaceutical separation processes, particularly in catalytic reactions where valuable catalysts, like palladium and platinum-based materials, need to be recovered. With GKN PM’s regenerable cartridge filters, businesses can retrieve these high value components and reduce waste, ultimately improving the sustainability of operations. By extending the lifespan of the cartridges, the filters also help businesses avoid the ongoing costs associated with disposable filters.

With engineering and support centers located in both North America and Europe, GKN PM is positioned to deliver responsive, regionally tailored service alongside globally consistent product quality. This ensures customers receive expert guidance wherever they are located.

The Metallic Membrane filter is available in different grades from 3µm down to 0.1µm and is accompanied by guidance from GKN PM’s technical support team to ensure customers receive the right fit and the best solution for their specific needs.

GKN PM will be in attendance at the upcoming Downstream trade show in Galveston, Texas on 25th and 26th June where the solution will be showcased.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News