3D Systems’ Extrusion Technology to Produce Patient-specific PEEK Implants Supports Ground-breaking Cranial Surgeries at Leading European Hospitals

- Patient-specific cranial implant produced with 3D Systems’ point-of-care additive manufacturing technologies used in pioneering surgery at University Hospital Basel (Switzerland)

- 3D Systems’ technologies enabled first 3D-printed cranial implant used in surgery at Salzburg University Hospital (Austria)

- Company’s additive manufacturing technologies enabling advances in cranial implants market — anticipated to reach more than $2 billion by 2030

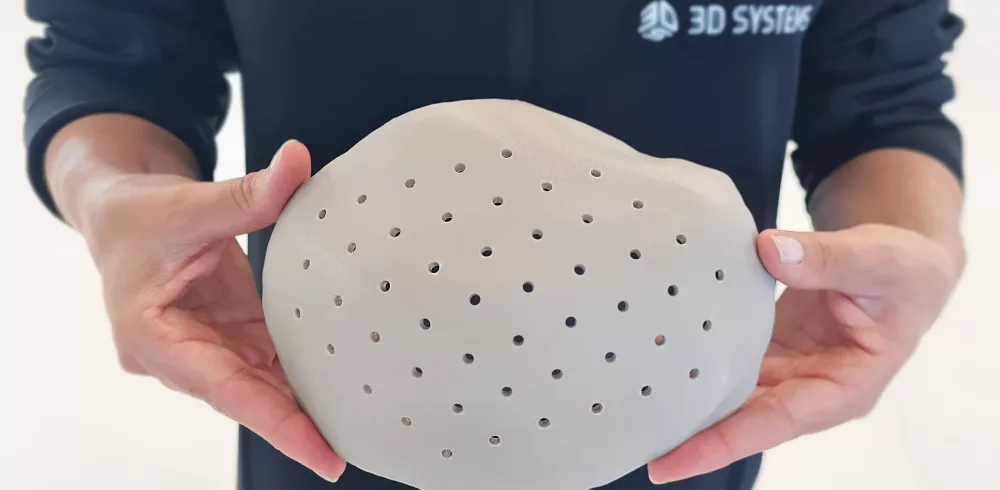

Today, 3D Systems (NYSE:DDD) announced a patient-specific 3D-printed cranial implant produced using its point-of-care technologies was successfully used in a cranioplasty at the University Hospital Basel (Switzerland). Under the leadership of Prof. Florian Thieringer, head of the Medical Additive Manufacturing Research Group (Swiss MAM) at the University Hospital Basel’s Department of Biomedical Engineering (UNIBAS DBE), and the Department of Oral and Maxillofacial Surgery (OMFS), in collaboration with Prof. Raphael Guzman and the Department of Neurosurgery, the team employed 3D Systems’ technologies to produce the first cranial implant at the point of care that complies with the current Medical Devices Regulations (MDR). 3D Systems’ extrusion printing technology is unique as its architecture and design are easy to use to produce durable, biocompatible implants using Polyetheretherketone (PEEK) material. Additionally, the technology enables the production of patient-specific geometries at the hospital itself providing tremendous benefits to both surgeons and patients. The implant created by the team at University Hospital Basel was used to successfully replace a section of disintegrating skull in a 46-year-old male who was experiencing complications from a stroke in 2019.

When the patient first entered Prof. Guzman’s care, he was experiencing visual disturbances, severe headaches, and dizziness, and his forehead was sinking due to a disintegrating skullcap. The University Hospital Basel team under the guidance of Dr. Neha Sharma, Ph.D. first took a computed tomography (CT) scan of the patient’s skull and imported that into software to create a model of the implant customized to his unique anatomy. The implant was then produced in the Hospital’s 3D printing lab using VESTAKEEP® i4 3DF PEEK by Evonik on 3D Systems’ EXT 220 MED extrusion platform. PEEK is a very desirable material for such applications due to its mechanical properties (i.e., lightweight, resistant to thermal and ionizing radiation, and similar to human bone). 3D Systems’ printing technology has been uniquely engineered to enable healthcare applications within sterile environments.

“The successful implantation at the University Hospital of Basel is a pivotal moment for medical 3D printing, demonstrating its potential to revolutionize patient care,” said Prof. Thieringer. “Our collaboration with hospitals across Europe, along with the invaluable expertise provided by POC APP AG around QMS and regulatory guidelines, showcases the power of advanced technology and collaboration in improving healthcare outcomes.”

3D Systems’ point-of-care solution was also successfully used by a team at Salzburg University Hospital, Department of Oromaxillofacial Surgery, to produce a patient-specific cranial implant for a 55-year-old male, Mr. Rainer Trummer, who suffered from craniosynostosis (i.e., one of the cranial bones ossified too early during childhood, resulting in a deformation of the skull). These technologies were brought together by the hospital’s in-house clinicians to successfully address the patient’s needs, providing a customized solution that best positioned the team for success. The hospital used Oqton’s D2P® software to create 3D models from the patient’s CT images and Oqton’s Geomagic Freeform® to complete the design of the patient-specific occipital prosthesis. The cranial implant was printed using VESTAKEEP® i4 3DF PEEK by Evonik on 3D Systems’ EXT 220 MED extrusion platform.

The solution has also been successfully deployed at the Department of Neurosurgery, University Hospital Salzburg, for patient-specific implants after decompressive craniectomy, which is regularly performed for aggressive brain swelling. According to Prof. Christoph Griessenauer, chairman of the department for neurosurgery in Salzburg, 40 decompressive craniectomies are performed in Salzburg annually. After the swelling subsides, the bone is replaced with a patient-specific cranioplasty implant. So far four cranioplasty surgeries have been performed within the last month, and multiple more are planned for the future. “We are proud now to use for the first time a patient-specific cranial implant printed at our hospital,” said Griessenauer. One of the departments’ senior attendings, Dr. Pöppe, was spearheading this effort from the clinical side. “This revolutionary procedure showcases the power of medical 3D printing in providing personalized solutions that adhere to regulatory standards. The success of these procedures marks a significant step forward in the integration of 3D printing into routine clinical practice,” said Dr. Pöppe.

“We are proud to be at the forefront of this medical revolution, leveraging our expertise in 3D printing to bring tangible benefits to patients,” said Stefan Leonhardt, director, medical devices, 3D Systems. “Our collaboration with hospitals in Europe demonstrates the potential of 3D printing to transform healthcare, and we are excited to continue advancing this technology to address a broader range of medical needs. 3D Systems remains committed to driving innovation in the field of medical 3D printing, working hand in hand with healthcare professionals to enhance patient care and contribute to a brighter, healthier future.”

It is anticipated that the use of 3D-printed cranial implants will accelerate based on the availability of advanced technologies. According to a report released by Acumen Research and Consulting in February 2023, the cranial implants market size in 2021 was roughly $1.2 billion and is anticipated to approach $2.1 billion by 2030. Cranial implants can address a breadth of applications including trauma, defects, and reconstruction. The continued innovation in materials and manufacturing methodologies such as 3D printing are expected to enable new solutions to catalyze growth in this market.

Forward-Looking Statements

Certain statements made in this release that are not statements of historical or current facts are forward-looking statements within the meaning of the Private Securities Litigation Reform Act of 1995. Forward-looking statements involve known and unknown risks, uncertainties and other factors that may cause the actual results, performance or achievements of the company to be materially different from historical results or from any future results or projections expressed or implied by such forward-looking statements. In many cases, forward-looking statements can be identified by terms such as “believes,” “belief,” “expects,” “may,” “will,” “estimates,” “intends,” “anticipates” or “plans” or the negative of these terms or other comparable terminology. Forward-looking statements are based upon management’s beliefs, assumptions, and current expectations and may include comments as to the company’s beliefs and expectations as to future events and trends affecting its business and are necessarily subject to uncertainties, many of which are outside the control of the company. The factors described under the headings “Forward-Looking Statements” and “Risk Factors” in the company’s periodic filings with the Securities and Exchange Commission, as well as other factors, could cause actual results to differ materially from those reflected or predicted in forward-looking statements. Although management believes that the expectations reflected in the forward-looking statements are reasonable, forward-looking statements are not, and should not be relied upon as a guarantee of future performance or results, nor will they necessarily prove to be accurate indications of the times at which such performance or results will be achieved. The forward-looking statements included are made only as of the date of the statement. 3D Systems undertakes no obligation to update or review any forward-looking statements made by management or on its behalf, whether as a result of future developments, subsequent events or circumstances or otherwise, except as required by law.

About 3D Systems

More than 35 years ago, 3D Systems brought the innovation of 3D printing to the manufacturing industry. Today, as the leading additive manufacturing solutions partner, we bring innovation, performance, and reliability to every interaction – empowering our customers to create products and business models never before possible. Thanks to our unique offering of hardware, software, materials, and services, each application-specific solution is powered by the expertise of our application engineers who collaborate with customers to transform how they deliver their products and services. 3D Systems’ solutions address a variety of advanced applications in healthcare and industrial markets such as medical and dental, aerospace & defense, automotive, and durable goods. More information on the company is available at www.3dsystems.com.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News