The first metal additive manufacturing machine for dental applications in Australia will be installed by Renishaw, in partnership with an Australian dental laboratory.

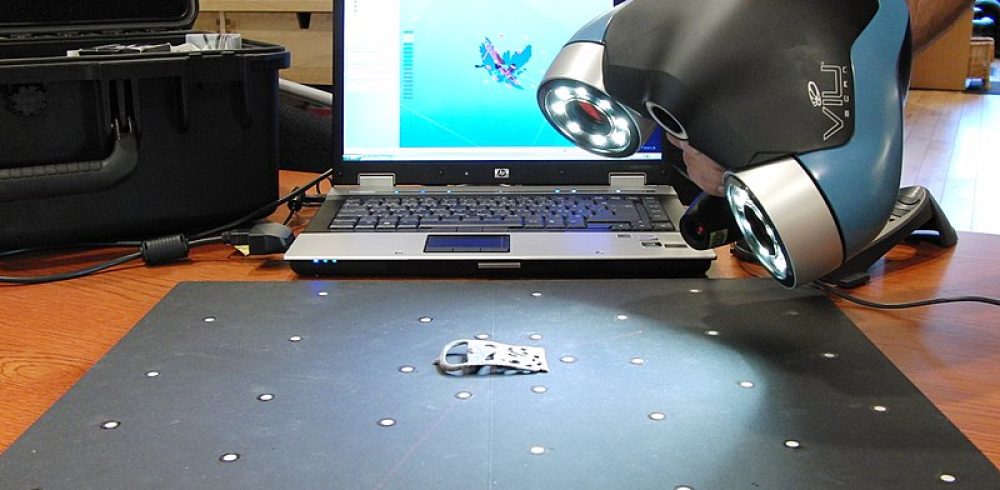

Dental laboratory Proslab introduced a partially digital workflow, as it used 3D scanning and design tools to design dentures, even before working with Renishaw. Once designed in CAD, the dentures were printed in resin and manufactured in cobalt chrome using traditional lost-wax casting, a traditional method which can reduce part accuracy due to uncontrolled heating and cooling, varied cross-sections and incomplete casting or gas porosity.

“Achieving a high level of accuracy with lost-wax casting is difficult. This means frameworks often need to be reworked after being sent to the dentist and fitted to a patient,” said Damian Synefias, CEO of Proslab.

In order to achieve better results, Proslab turned to Renishaw to fully digitalise its manufacturing process by using additive manufacturing (AM) and purchased Renishaw’s AM 400 metal AM system. The machine enables the production of removable partial dentures directly from a CAD file, eliminating the additional casting step. Frameworks are built in 40-micron layers of CE marked cobalt chrome powder and built by laser powder bed fusion (PBF), using an ytterbium fibre laser.

After the purchase Proslab has confirmed that since it started directly printing from a CAD file, it reduced the number of in-house remakes due to error by 100%.