Logistics operators can now easily check the fill level of their intermediate bulk containers (IBCs) thanks to a new service launched by leading returnable plastic packaging supplier Schoeller Allibert. Schoeller Allibert is pleased to announce the launch of the Fill Level feature for its logistics tracking platform, SmartLink®.

Fill Level keeps its users informed of how full their IBCs are, enabling them to quickly and conveniently schedule refills to maximise usage, productivity and profit.

The system is designed to streamline fill level monitoring, which typically involves manually checking each container at the cost of time and manpower.

Nick James, Sales Director, at Schoeller Allibert said: “It always pays to know just how full – or empty – your IBCs are. Fill Level does exactly what its name suggests – it provides you with a constant stream of data on the fill levels of your logistics assets. This is a revolutionary improvement for managing a critical status element for liquid and other variable assets and helps to put logistics operators back in the driver’s seat when it comes to managing their business.

“With this new feature, Schoeller Allibert’s top-of-the-line SmartLink® system takes the guesswork out of IBC management. Fill Level tells you what you need to know, when you need to know it, letting you take the appropriate action to keep your business moving.”

SmartLink® lets operators monitor the status and movements of their assets by connecting them to the internet. As well as informing users of an asset’s location, it can monitor its interior temperature – and through the new Fill Level feature can also provide updates on the fill status. Via SmartLink®, Fill Level can also set an alarm if or when assets fall below a certain fill threshold.

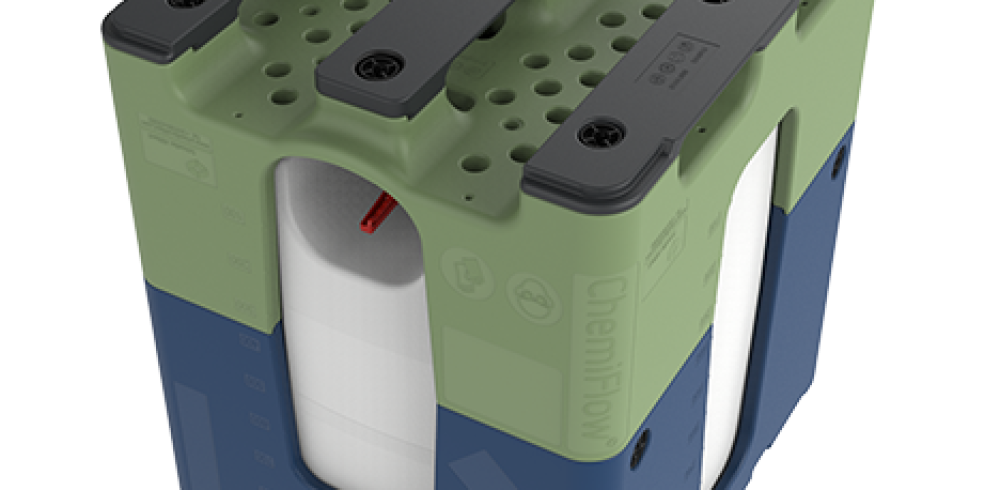

Fill Level is natively integrated into ChemiFlow®, Schoeller Allibert’s family of bulk containers specifically designed for the transport of hazardous materials.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News