Polypaper: The Eco-Sustainable Coating That Makes Paper Waterproof and Resistant

• Nanoprom Chemicals has found a way to prevent paper straws and cardboard packaging from getting soaked and deteriorating when in contact with a liquid or due to rain.

• The solution is 100% sustainable and allows complete recycling of materials

We all agree that it is necessary to change our lifestyle to protect the environment. But let’s be honest: the paper or durum wheat straws that are used today instead of plastic ones, after just ten minutes of being immersed in the glass, absorb part of our drink and become soaked or even melt. They are necessary, but they represent a sort of compromise that makes no one happy. But, above all, there is no quality control during the production process and no one knows what the real binder is that is released into our drinks.

However, the Nanoprom Chemicals Benefit Company, a company that operates in the surface treatment sector based in Sassuolo (MO), has found a way not to ruin our right to an aperitif and not to be tempted by the commitment we have to make in the dealing with the Planet.

The solution, as simple as it is ingenious, is called Polypaper and is nothing more than a coating made with cold vitrification processes of the straw without altering its structure. As the CEO of Nanoprom Chemical Gian Luca Falleti explains: «Our product, tested in the food sector, has a high hydrophobic power, makes the paper resistant to liquids without interfering with its recyclability, because the Polypaper coating is mainly composed of silica, an inert and biocompatible mineral substance.” Furthermore, a straw treated with Polypaper is totally tasteless. Indeed, it even gives the sensation of drinking from the neck of a glass bottle, unlike the traditional one which often releases an unpleasant aftertaste.

It’s not all. “Environmentally friendly” paper straws often contain traces of PFAS (perfluorinated and polyfluorinated alkyl substances) which, in addition to being polluting, are also harmful to health, because they interfere with the endocrine system causing

imbalances in the immune system, fertility , of development in the evolutionary age. According to a team of researchers from the University of Antwerp – the first in the world to have carried out an analysis of this kind – of 39 brands of straws, 27 contained traces of PFAS, for a total of 18 different chemical substances. The Polypaper protective treatment avoids this danger, since it makes the straws water-repellent and therefore more resistant to contact with drinks.

From the straw to the packaging

The example of the paper straw may seem like a small matter but it is not. First of all because two billion straws are produced every day, making it a truly important business. And then, because Polypaper can be used in numerous other sectors.

For example, that of packaging. We are surrounded by goods of all kinds protected by cardboard packaging. Food, furniture, appliances, technology products, medicines, toys: the list can be endless. In the last decade, cellulose-based packaging has gone from 4.33 million to 4.92 million tonnes (source Comieco-Conai), with an increase of approximately 600 thousand tonnes. At the same time, manufacturers have gradually reduced the average weight of cardboard to offer the market packaging solutions that are increasingly lighter and more eco-sustainable, but also less resistant to bad weather.

The boxes, despite being ecological, have a flaw: in contact with water they fall apart with the risk that what they contain will be ruined. And this is where, once again, Polypaper comes into play which, thanks to its water-repellent properties and by virtue of the low surface tension it creates on the covering, ensures that the drop of water is not absorbed but slides away, maintaining the waterproofed box.

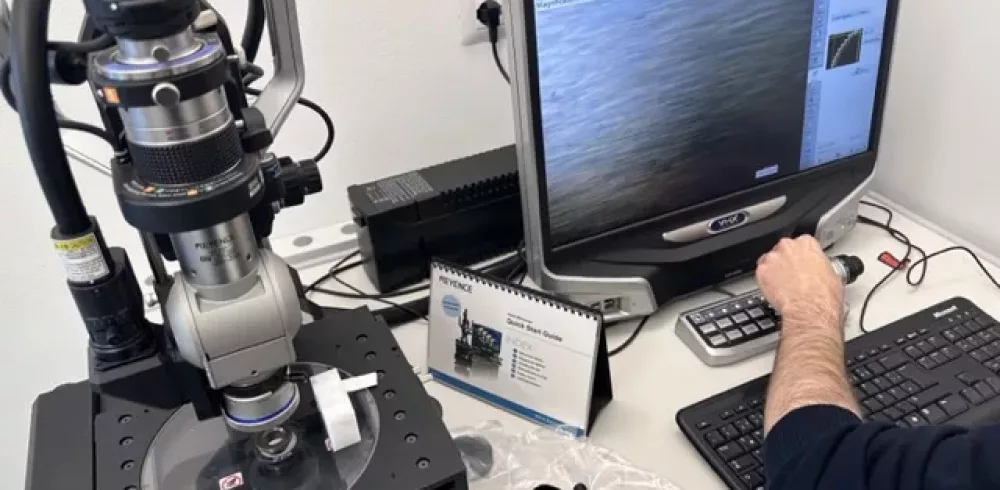

Through empirical experiments it was noticed that by leaving some cardboard packaging exposed to the elements for five months, the untreated ones were clearly damaged while the others, “vitrified” with Polypaper, remained substantially intact.

Finally, studies certified by accredited laboratories in the ceramic world have demonstrated the effectiveness of this solution both from a chemical point of view – because Polypaper by Nanoprom Chemicals does not release dangerous substances – and from that of sustainability, since the treated cardboard is totally recyclable. And the Company, strengthened by these positive results, is studying the feasibility of building an automated packaging plant in the ceramic sector which, when fully operational, will generate a reduction of approximately 8 million square meters of plastic per year. The headquarters of the factory will be in the territory of Sassuolo, a town considered the capital of ceramic tiles.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News