Linear guides are crucial for smooth, low-friction movement in packaging, food processing and transportation industries. That’s why components manufacturer, norelem, has developed four specialised product ranges of linear roller guides to meet diverse industry needs, ensuring reliability, low maintenance and adaptable functionality.

In line with its commitment to innovation, norelem’s linear guide rails are designed to fulfil diverse assembly requirements and application demands. These rails are complemented by norelem’s roller guide carriages, seamlessly integrated to accentuate their quality and adaptability. With a wide selection of models, norelem guarantees each roller guide carriage is customised for optimal precision and efficiency.

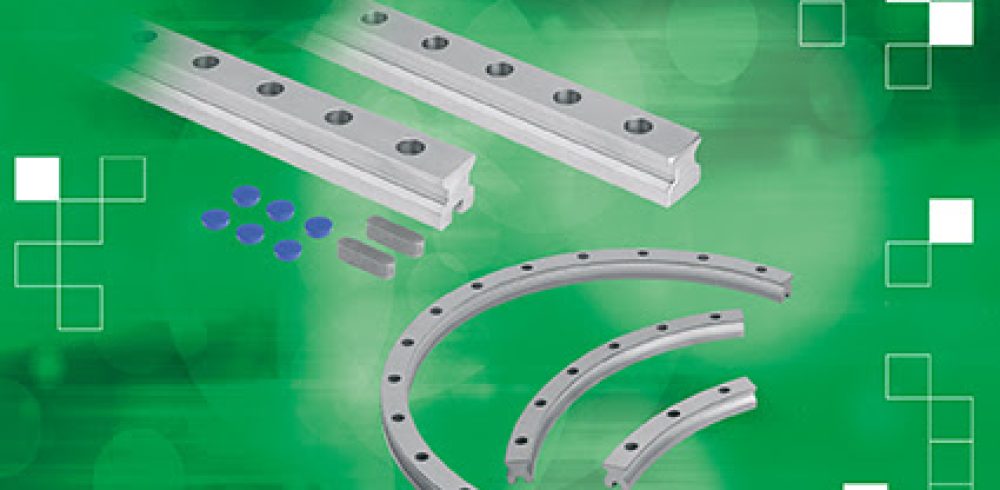

The range includes straight linear guide rails (21355) which emphasise simplicity and reliability in linear motion. These are available in standard lengths of 500, 1,000 and 2,000 mm, and are extendable up to 4,000 mm upon request, offering versatile top-mounting options and compatibility with roller guide carriages, for smooth motion and robust load-bearing capacity. Ideal for transportation applications such as interior doors on ships and trains, ensuring quiet and dependable operation while enhancing efficiency and comfort.

Alternatively, curved linear guide rails (21356) are designed for scenarios where straight-line movement isn’t feasible. These offer flexibility to navigate pre-defined curves and optimise space in constrained environments. The components support complex motion profiles essential for precision applications like CNC machining and 3D printing, ensuring accuracy and repeatability along curved paths.

Complementing the linear guide rails are norelem’s roller carriages. The roller carriage for straight linear guide rails (21350) compensates for deviations of approximately 0.05 mm, which is ideal for maintaining hygiene and safety standards. Meanwhile, the roller carriage for linear guide rails (21351) extends versatility with a tolerance range of about 0.5 mm, perfect for the packaging industry as it is suitable for both straight and curved rail journeys, enabling efficient and accurate product transportation.

These carriages excel in performance, boasting a maximum acceleration of 50 m/s² and a traverse speed of up to 5 m/s. With a one-sided preload mechanism, these components adapt to rail contours, ensuring consistent sliding resistance, reducing wear over time and simplifying installation. These components also eliminate the need to adjust rollers to match rail width using an eccentric pin, guaranteeing smooth, slip-free movement while streamlining the process.

Marcus Schneck, CEO of norelem, commented: “Our expanded range of linear roller guides is engineered to meet the rigorous demands of modern industry applications. Whether in packaging, food processing or transport, these guides offer unparalleled precision, reliability and ease of use, showcasing our commitment to providing solutions that enhance operational efficiency and longevity.”

norelem’s linear roller guides stand out for their unwavering commitment to seamless movement and optimal performance, catering to diverse industries and ensuring businesses can rely on consistent excellence in their linear motion solutions.

To discover the new range of norelem linear roller guides and find the perfect solution for your application, visit the norelem website.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News