As industries around the world strive to balance motor performance with environmental responsibility, IE efficiency ratings have emerged as a critical benchmark for engineers. Electric motors account for more than half of global electricity consumption, making the shift to higher-efficiency motors not just beneficial — but essential. With the anticipated IE6 efficiency rating set to change the industrial landscape, businesses stand to gain significantly in both cost savings and sustainability.

Marek Lukaszczyk, marketing manager for WEG Europe and the Middle East, shares insights into the latest IE6 motor technology and its potential for the process industries.

Understanding motor efficiency ratings

The International Electrotechnical Commission (IEC) has long served as the global standard-setting body for electric motor efficiency. Through its IEC 60034-30 standard, the IEC defines energy efficiency categories for motors, each corresponding to a specific level of energy loss. The higher the rating, the lower the energy losses and the greater the efficiency.

At the lower end of the scale, IE1 motors are considered standard efficiency. As you move up, IE2 and IE3 represent improved and premium efficiency levels, reducing energy losses by roughly 20 per cent with each step. IE4 motors, categorised as super-premium efficiency, cut losses even further, while IE5 motors, classified as ultra-premium efficiency, reduce losses by an additional 20 per cent. These incremental improvements have made electric motors central to global energy efficiency initiatives.

Given that electric motors account for a large share of global energy consumption, they have become a primary target for regulatory improvements. The EU’s Regulation 2019/1782 on electric motors and variable speed drives introduced stricter standards in both 2021 and 2023, requiring new motors to meet IE2, IE3 or IE4 efficiency levels depending on their specifications. In fact, the EU became the first region to mandate IE4 efficiency for certain motor categories, setting a precedent for sustainability worldwide.

The rise of IE6: pushing boundaries further

But the journey towards even greater efficiency doesn’t stop there. The anticipated IE6 classification promises to push energy efficiency even further, targeting a 20 per cent reduction in energy losses compared to IE5 motors. While this new standard has yet to be officially codified or mandated by regulation, motors that meet the expected IE6 benchmarks are already available.

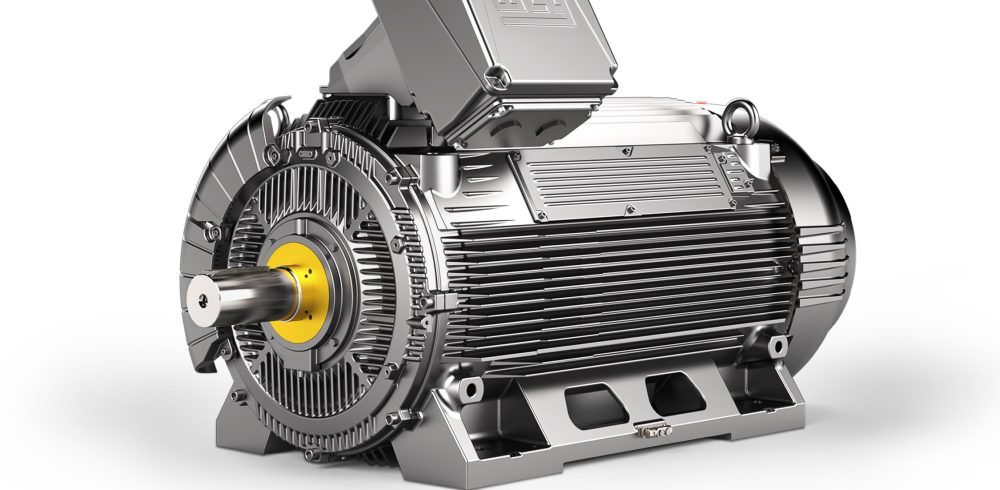

A prime example of this leap forward is WEG’s W23 Sync+ Ultra motor, which has already been adopted across various industries since its launch in May 2024. Offering the highest efficiency level on the market — meeting the anticipated IE6 standard — the W23 Sync+ Ultra represents a significant step forward in motor technology.

Unlocking potential in energy-intensive industries

As motor efficiency continues to improve, its impact on energy-intensive industries becomes increasingly evident. Sectors such as chemical manufacturing, oil and gas and food processing are particularly well-positioned to benefit from the cost-saving advantages of IE6 motor technology.

In these industries, where energy consumption accounts for up to 97 per cent of a motor’s lifecycle costs, switching to more efficient motors can result in significant savings. Motors are crucial for continuous operations like pumping, compressing and conveying, and higher-efficiency models reduce both operational costs and the environmental footprint.

Moreover, more efficient motors can help extend equipment lifespan by generating less heat, which is essential in industries with harsh operating conditions. For example, the W23 Sync+ line operates across a wide speed range while maintaining torque, eliminating the need for additional cooling systems or ventilation. This reduction in thermal stress helps to minimise maintenance needs and prevent costly downtime.

In addition to operational and maintenance benefits, the environmental advantages of IE6 motors are undeniable. By reducing electricity demand, they contribute to a significant reduction in CO2 emissions. Transitioning to IE6-rated motors not only supports regulatory compliance but also helps companies achieve their sustainability goals, particularly as many industries now integrate Environmental, Social and Governance (ESG) objectives into their core strategies.

The future: IE6 and beyond

At WEG, years of dedicated research and development have resulted in motor designs that not only meet but exceed the anticipated IE6 standards. The W23 Sync+ Ultra motor stands as a testament to this achievement, offering a 20 per cent reduction in energy losses compared to IE5 motors.

The motor integrates permanent magnet and magnetic reluctance technology, eliminating induced currents and drastically reducing overall motor losses. It offers a broad power range, from 0.75 to 1250 kW, and is available in frame sizes from 80 to 450 H/G. Capable of operating at speeds up to 3600 RPM, the motor is engineered to endure tough conditions with IP55 protection and F-class insulation, guaranteeing dependable and high-efficiency performance even in the most demanding environments.

This milestone paves the way for even greater advances in motor efficiency. More recently, WEG achieved a groundbreaking development with a 500 Kw W23 Sync+ ULTRA motor meeting the future predicted IE9 efficiency classification. This motor demonstrated an impressive 98.8 per cent efficiency at 500kW — a result validated by rigorous dynamometer testing.

Powered by cutting-edge permanent magnet technology and proprietary innovations, this IE9 motor delivers extraordinary performance. Compared to an IE4 motor, the IE9 motor can cut CO2 emissions by 294 tons over its lifespan.

Such advancements not only align with global sustainability efforts but also reaffirm WEG’s role as a leader in driving the industrial sector toward a greener, more energy-efficient future.

As industries strive to enhance motor performance while meeting sustainability goals, IE ratings have become a critical factor for engineers, plant managers and board level executives alike. With motor technologies already meeting the IE6 standard, the opportunity is clear: adopting this next-level efficiency is not just a choice, but a crucial step towards driving cost savings and environmental responsibility in the future.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News