Masca ID Gives a ‘Damm’ About Traceability in Beverage Industry

Multinational brewer uses high speed CO2 lasers to apply vital information to beer bottle necks & labels and to mark cardboard cases for multipacks

Macsa id (https://www.macsa.com/en-uk/) – a leading manufacturer of advanced coding and marking equipment for the global food and beverage industry – has reinforced its long-standing relationship with Spanish brewing company, Damm with the installation of several additional CO2 laser coding systems at its state-of-the-art facility in El Prat de Llobregat in Barcelona.

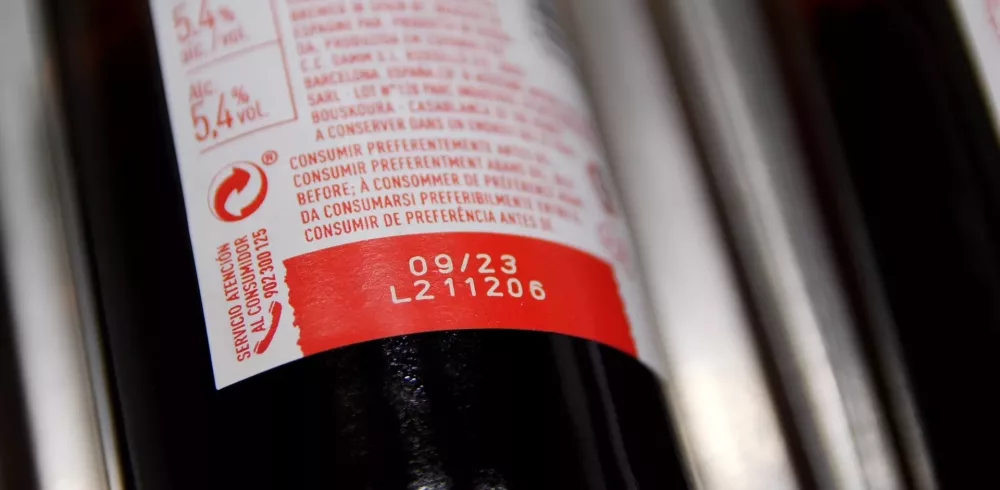

Supplied as part of a new packaging line, two Macsa id KIP 1110 110W ultra high speed (UHS) wash down laser machines are applying batch codes and expiry dates onto the labels and collars of returnable glass bottles, while a SPA2 C 30Watt model is marking cardboard transit cases for multipacks.

Damm manufactures, packages and distributes beer, water and soft drinks. The multinational business also has a number of subsidiaries that provide catering, capillary and distribution of beverages, food and other products for the hospitality industry. Damm is actively present in more than 130 countries and has over 5000 collaborators and partners.

One of Macsa id’s established customers, Damm already had 13 of the company’s CO2 lasers in operation at the El Prat de Llobregat factory, with power ranging from 30 to 110 Watts.

As a result, and in a move to further strengthen its production processes and operating efficiencies, Damm once again chose Macsa id coding and marking equipment to mark glass bottle necks, labels and cardboard multipack cases on the plant’s 15th packaging line.

With capacity up to 60,000 bottles per hour, the Macsa id KIP 1110 lasers are integrated into Damm’s labelling systems and carousels, allowing the marking position to be adjusted according to the container format.

Macsa id’s KIP 1110 laser models are used across a range of packaging applications including for marking paper and cardboard, glass, ceramics, coated materials, PET and PVC. The DUO dual processing technology allows high speed, superior quality marking of variable data. A selection of software options is also supported that allows it to be operated both remotely and directly.

The machine’s protective cover is designed to facilitate operation in dusty or humid environments. The enclosure has been redesigned with a flat front surface allowing simple integration of vision systems and other devices.

The Macsa id SPA2 C 30W laser system has been installed for coding onto cardboard cases for Damm’s multipacks of bottles and can of beer. The laser removes the surface layer of cardboard for high contrast and excellent text legibility.

Lluis Moras, Macsa id’s technical manager comments: “The CO2 laser marking equipment chosen by Damm offers the security of perfect integration into the company’s production processes.

“At Damm, they trust their coding and traceability operations to Macsa id, both because of the quality of our products, and our technical service and support.”

Boasting a modular design, Macsa id’s flexible SPA2 lasers can be easily integrated with any production line or application. Exceptionally easy to install, program and operate, a wizard supports installation and online help videos, technical guides and tips can be accessed via a new 10-inch handheld touchscreen controller designed to make programming quicker and to eliminate operator errors. The lasers can also be controlled direct from a PC via an ethernet link or PLC with Profinet or OPC-UA.

The SPA2 connector box offers a wide range of communication ports, enabling the system to be integrated with all elements of the production line. These new lasers support Macsa’s Optima software for real time control and compatibility with desktop printers, label printer applicators and label applicators.

Macsa id’s SPA2 laser coders are available with a comprehensive range of software, accessories and services. The environmentally-friendly units are fume, waste and consumable free plus use less power and energy.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News