Laser manufacturers tell it best; the future of laser looks bright for fibre lasers and estimation for the next decade is a replacement of original welding technologies in favour of fibre lasers. Indeed, the diode pumped fibre lasers are cheaper, with lower ongoing cost of maintenance, spare parts and are environmentally friendly.

At Pyramid in May 2019, decision was taken to develop our range of laser welders to include a fibre laser with an oscillating head. This white paper aims to present an overview of the journey to the optimisation of the welding process of aluminium packages in a sensitive industrial application.

What is CW fibre laser with oscillating head?

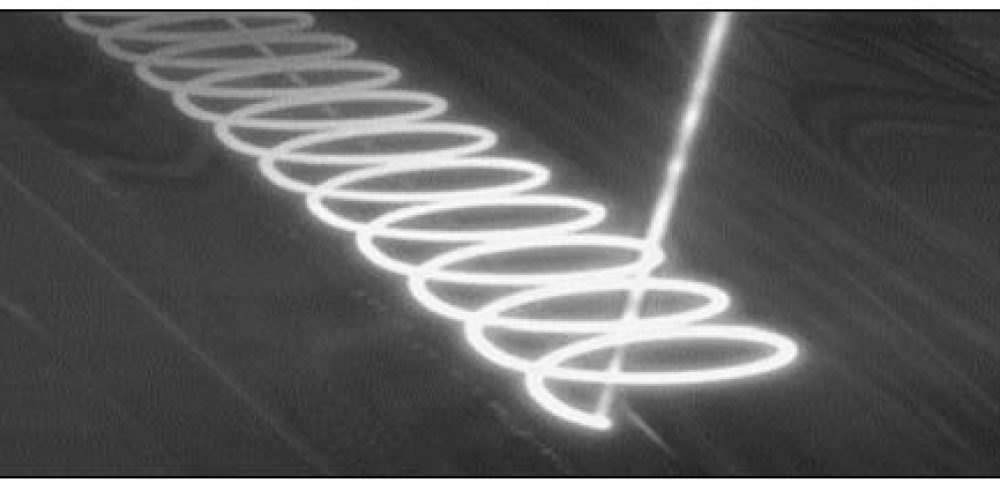

Continuous Wave (CW) laser are lasers that have the ability to deliver a continuous beam of intense light. With the right optics this beam can be focused to a 51μm diameter spot, which is for comparison 10x smaller than an equivalent pulsed Nd: YAG laser (0.7mm). To generate a weld, the beam is oscillated along the weld path by a scanner head, using mirrors that can handle high power lasers of 1.5kW.

These characteristics enable reaching high power density which is enough to melt most metals and in some circumstances vaporize it. This enables to classify 2 type of welds respectively named conduction limited and keyhole welding [1]. Strong interactions exist between the molten pool and the fibre laser beam which can lead to poor welds, when left uncontrolled. The issue we encountered originally existed in deep and narrow key hole welding.

However, this effect was also witnessed in shallower welds as well, in conduction-limited mode. (penetration depth / weld width < 0.5) [2]

Plasma formation in Key hole welding appear when metal is vaporized (see figure 2). It can also generate beam scattering effects, causing poor welds. Pictures and evidence are shown (see below). To solve these problems, we have sought the advice of laser processing experts such as Paul Harrison (SPI Lasers) and William STEEN, co-writer of Laser Material Processing (SPRINGER).

Plasma like “ball” formation and beam scattering

Above the keyhole entry the temperature can rise, because of effects such as thermal lens focusing or reflection focusing of the molten pool [3]. When a gas is heated to a high temperature it can be ionised and turn into a plasma, where metal vapour and dust can be aggregated which generate a “plasma ball” scattering the incoming laser beam in multiple direction (see figure 2) [3].

Importance of shield gas – extract setup

To prevent the above situation, a setup comprising of extractors and/or shielding gas is required. The type of gas used as shield gas is important, neutral and inert gas should be preferred as they interact less with the molten pool. Varying results were seen during our trials of different setups. Eventually one proved to be repeatedly successful, which comprised of a shield gas jet on one side and extracts on the other. (see illustration below)

We used Nitrogen as the shield gas jet in a controlled atmosphere composed of a majority of nitrogen and 5% Helium. Below are 2 identical packages, welded with the exact same parameters. One without extract and shield gas, the other one with.

Note: Here, shroud gas/shield gas/extract play little importance in protecting the optics. Indeed, the focus distance (+200mm) is away from the work area and so protected from splatters and smokes.

Fillet weld – importance of lid positioning

Regarding the type of weld to achieve the importance of the position of the lid varies. Welding of butt joints the gap is around 0.1 ~ 0.2mm (reference to SPI Lab Reports) between the 2 welded pieces the weld quality is not impacted. However, with fillets welds, a lid misalignment will cause the weld to have an unequal weld path. Unlike butt welds which are on a level plan. The flow of molten metal is therefore distributed more evenly. Below is picture and cross-section of 2 opposite edges of a fillet weld on the same package on which the lid has been misaligned.

By observing the sections above, we can tell the weld shape is different. One has been welded more on the housing (left), the one more on the lid (right).

However, the cross sections highlight that a small misalignment of the lid has in fact limited impact on the internal structure of the weld. Minor impact on the width (1.14mm / 1.18mm) and a reasonable impact on the depth of the weld (0.70mm / 0.53mm).

Operating Characteristics

Compared to fixed optics, this technology of laser is highly flexible. Weld depth and width can be controlled independently, making it more forgiving in terms of gap and tolerances for welded devices.

The power, amplitude, frequency and average speed should be the main parameters to consider. In some applications heat distortion is critical (i.e. fibre optic telecommunication devices) therefore the aim is to keep it as low as possible. Our case study on aluminium package (grade 4047-lid to 6061-housing) showed optimum results were achieved with the following setup:

Table – Non exhaustive overview of process parameters and their effect on the weld characteristics

Summary

In conclusion, welding aluminium grade 4047 to 6061 in an industrial environment has been a success using a fibre laser with oscillating head. Further positive tests in the laboratory showed good quality and consistent welds can also be achieved on many different metals using the extended process window offered by this new technology.

The welding potential of the following metals have been either proven in the laboratory and/or already confirmed in an industrial application:

- Aluminium grade 4047; 6061

- Silicone Aluminium

- Stainless steel grade 304; 316

- Titanium alloy Ti-6Al-4V

- Brass 95/5

- Kovar…

References

[1] W. M. STEEN; J. MAZUMDER, 4th Edition, Laser Material Processing, Laser welding, Process Mechanisms – Keyholes and plasma, p.204.

[2] INDUSTRIAL-LASERS.COM, Industrial laser solutions, Recent advances in fibre laser welding. May 1st, 2018. https://www.industrial-lasers.com/welding/article/16485184/recent-advances-in-fiber-laser-welding

[3] Li Qun Li, The Characteristics of the Plasma in Laser Keyhole Welding. (2004) Conference Paper, State Key Laboratory of Advanced Welding Production Technology, Harbin Institute of Technology, Harbin, 150001, China

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News