Fast, Easy, Accurate & Affordable Forming Simulation : Are you under pressure to deliver error-free metal formed products first time and at a reduced cost?

Metal formed parts need to meet rigorous quality, safety and performance standards, but the standard approach to develop formed parts can leave manufacturers open to initial results that require time-consuming and costly re-work. To combat this, the use of robust simulation technologies are becoming more commonplace during the product development process, enabling manufacturers to eliminate potential issues before physical parts exist.

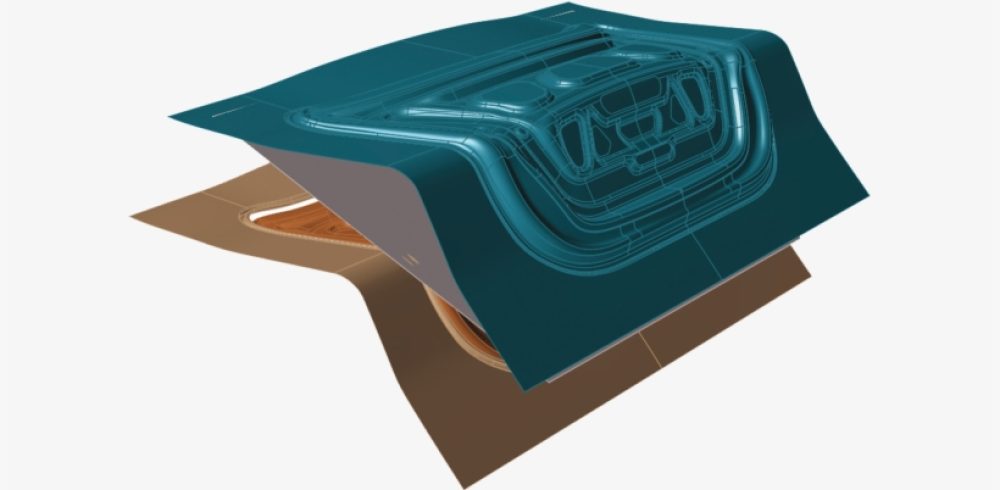

This free to attend live webinar hosted in association with Confederation of British Metalforming (CBM) taking place on 14th October 2020 at 14:00 -15:00 pm BST will demonstrate how you can simulate your metal forming manufacturing process to efficiently predict and eliminate issues early, accelerating the manufacturing process and reducing material costs with Altair Inspire Form. Altair Inspire Form is a sheet metal forming simulation software that enables cold and hot sheet metal forming, tube bending, hydroforming, and composite forming are supported.

In this webinar attendees will learn how to analyse parts in seconds to predict formability early in the product development cycle, how to automate blank nesting proposes an efficient layout of the flattened blank on the sheet coil to maximize material utilization and how to iterate and simulate multi-stage forming, trimming and springback in a modern and intuitive user interface, reducing complexity and making the production of high quality parts more economical.

This webinar is ideal for all those involved in the delivery of efficient and profitable metal formed products; including designers, process engineers, manufacturing specialists and CAE analysts, as well as business leaders who are interested in saving costs in today’s challenging environment.

Register Now: https://hubs.ly/H0xgRTy0

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News