As energy costs continue to rise across the UK, manufacturers face increasing pressure to control consumption, intelligently manage procurement, and find efficiencies throughout their operations. The Energy Intensive Industries Relief Scheme, network charge reforms, and fluctuating wholesale gas and electricity markets have combined to make energy one of the most volatile and complex overheads facing British industry today.

For many manufacturers, energy represents an increasing percentage of total operating costs. In a sector where margins are often tight, taking a proactive approach to energy management is no longer optional, but essential for competitiveness and long-term stability.

To gain an edge, a business must understand how energy markets affect procurement and risk, have a clear grasp of the evolving structure of utility invoices, build strong relationships with suppliers, and manage exposure to price volatility through an informed buying strategy. It must also stay compliant with government initiatives such as the Energy Savings Opportunity Scheme (ESOS) and Streamlined Energy and Carbon Reporting (SECR), while identifying hidden costs such as excessive kVA capacities or unfavourable Targeted Charging Review (TCR) bandings. Expecting internal staff to manage all of this without specialist knowledge is unrealistic. That is why more manufacturers are turning to dedicated energy partners who can provide expert guidance, continuous monitoring, and strategic insight to help reduce costs and emissions.

Yet finding a capable partner is not straightforward. Energy brokerage remains an unregulated industry, meaning that the quality of service varies enormously. The difference between a proactive, data-driven broker and an inexperienced or complacent one can be measured in hundreds of thousands of pounds each year, if not more.

Procurement: Buying Smarter, Not Just Cheaper

Effective procurement is the foundation of any successful energy strategy. However, for many businesses, the tender process can be a labyrinth of complex contracts and variable charges. Professional brokers have access to multiple suppliers and wholesale markets, enabling them to conduct competitive tenders and provide transparent comparisons between offers. By analysing a company’s historical consumption and forecasting its future needs, they can model the cost implications of different contract structures with accuracy.

Consider a medium-sized manufacturer consuming around six million kWh of electricity each year. In the current market, initial contract offers could range from £1.3 million to £1.45 million annually, leaving a potential gap of £150,000 for essentially the same amount of energy. A skilled broker can explain these variations, often identifying hidden differences such as pass-through charges or volume tolerance clauses, and recommend the contract that delivers the best long-term value.

Timing is equally crucial. Energy markets fluctuate daily, and locking in a contract at the right moment can have a dramatic impact. Securing an agreement even two weeks earlier than a market peak could save a business tens of thousands of pounds, whilst securing at the wrong time, can see the same costs increase in the wrong direction.

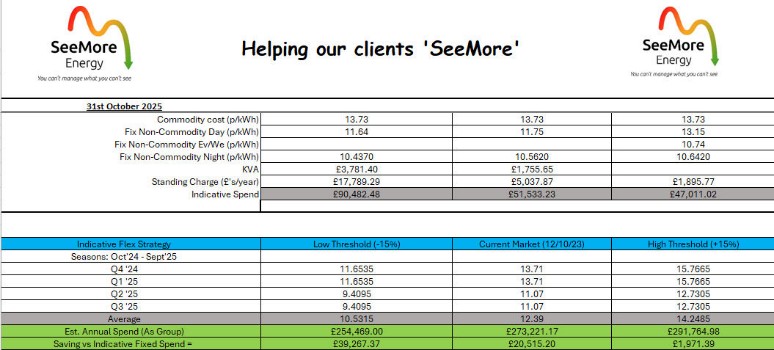

For many manufacturers, flexible procurement contracts are becoming increasingly popular. These allow businesses to purchase energy in tranches throughout the year, allowing the purchaser to take advantage of market fluctuation, DE minimising the risk of a single contract acceptance covering a sustained period of cost for the business, however, this approach requires genuine market intelligence and can be daunting for those who lack experience with energy markets. A capable broker will monitor global and domestic price indicators — from gas storage levels and LNG imports to weather forecasts and geopolitical events — to decide when to buy or wait. Those who capitalised on falling wholesale prices during early 2024 typically managed to lock in commodity costs 15-20% below currently available prices. On an annual energy spend of £1 million, this equates to savings of £150,000 to £200,000.

Invoice Validation: Stopping Errors Before They Cost You

Securing a competitive contract is only half the battle. The next step is ensuring that the charges being applied are correct. Industry studies suggest that as many as one in five UK energy invoices contain an error. This can be due to incorrect rates, estimated reads, or misapplied charges.

An experienced broker will employ invoice validation systems to check every line of every invoice against the agreed contract rates and metering data before payment is made. A broker that uses an invoice validation system can catch these errors before any payment is taken and then manage the query to conclusion, recovering funds where necessary. For a multi-site manufacturer with an annual energy spend of £2.5 million, even a two per cent overcharge amounts to £50,000 per year in erroneous costs.

Historical invoice audits can uncover even more value. Under Ofgem’s back-billing rules, businesses can reclaim overpayments for errors made for inaccurate invoices issued for historical usage beyond the previous twelve months, while VAT errors can be corrected for up to four years.

Accurate invoice validation also improves future forecasting, as the process provides an ongoing stream of reliable consumption data that can be used to refine budget projections and energy models.

Customer Service and Query Management: Freeing Up Man Hours

For manufacturers operating across several sites, with multiple meters and suppliers, managing queries can quickly become a full-time job. Waiting weeks for a supplier to respond to a metering issue or billing error is frustrating and costly. A dedicated energy partner serves as a single point of contact, handling all supplier communications, chasing responses, and providing clear progress updates. Many also provide online dashboards where clients can track the status of all ongoing queries in one place.

This support can save substantial time. A production manager who spends just five hours per week dealing with supplier queries loses around 250 hours of productivity each year. This is time that could be better spent managing operations or driving improvements. By taking on this responsibility, a broker frees up internal teams to focus on what they do best.

An experienced energy partner will also know how to escalate issues effectively. They can invoke supplier service-level agreements to ensure timely responses, use their knowledge of escalation channels to obtain quicker resolutions, engage with Distribution Network Operators on metering and network problems, and raise disputes with the Energy Ombudsman if necessary. This not only improves quicker outcomes, but often secures conclusions that may a business may not be able to achieve on its own.

Net Zero, Compliance, and Government Incentives

The UK government’s legally binding target of achieving net zero by 2050 means that every manufacturer must now consider how energy consumption and carbon emissions are measured, reported, and reduced. Compliance schemes such as ESOS and SECR have made carbon reporting an obligation, and failing to comply can lead to penalties as well as reputational damage.

A competent energy partner can help a business prepare ESOS audits, compile accurate carbon data for SECR submissions, and design cost-effective strategies to reduce emissions. Beyond compliance, brokers can identify opportunities to claim relief through schemes like the Energy Intensive Industries (EII) exemption. For eligible sectors this scheme can reduce certain policy-related costs by as much as 85%, translating into annual savings of £60,000 to £150,000 for medium to large manufacturers.

An energy partner should not only be making their clients aware of these schemes but assisting with every step of the application and then verifying that the supplier is accurately applying the discounts.

Solutions and Lowering costs

Many manufacturers overlook the charges associated with their network connection, even though these can represent a significant portion of total costs. kVA capacity and TCR banding are two key areas that are often misunderstood but can offer substantial savings when managed properly.

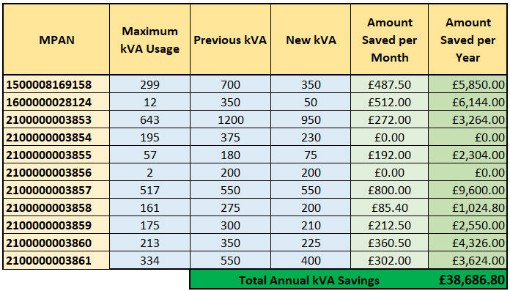

Every electricity meter has an agreed kVA (kilovolt-ampere) capacity, which determines how much power is available to the site. If the capacity is set too high, the business pays for unused capacity. If it’s too low, excess capacity charges are applied when demand exceeds the limit. Monitoring and adjusting these levels regularly can make a real difference. A recent example of this saw a review for a business with ten electricity meters identify that by adjusting their kVA capacities to the correct levels, a saving of almost £40,000 per year could be achieved.

Since Ofgem’s Targeted Charging Review restructured the way network costs are recovered, TCR banding has become another area where close attention pays dividends. Sites misclassified into higher bands can find themselves paying tens of thousands more than necessary. A broker who reviews these settings annually ensures charges are aligned with actual usage, preventing unnecessary overspend.

A good broker does more than negotiate contracts. Many now assist manufacturers in exploring on-site generation, storage, and efficiency projects. These might include solar PV systems, battery storage, electric vehicle charging infrastructure, or advanced energy monitoring platforms.

Installing a 500 kWp solar array on a factory roof can generate around 450,000 kilowatt-hours per year. For many sites this can represent a significant portion of a plant’s consumption. At an average grid electricity cost of 20 pence per kilowatt-hour, this equates to a £90,000 annual saving, with a payback period of between three and six years.

Even smaller improvements can have a major impact. Energy audits frequently identify opportunities which can reduce energy use by ten to twenty per cent with paybacks of less than two years. According to the Carbon Trust, many UK manufacturers could achieve double-digit energy savings through low-cost operational adjustments alone.

Brokers with strong networks can connect clients with reputable technology providers, negotiate preferential pricing, and ensure that project payback calculations are realistic and achievable.

Reporting, Communication, and Ongoing Support

Energy management is not a one-off exercise but a continuous process of measurement, reporting, and improvement. A reliable energy partner will provide monthly performance reports showing consumption trends, cost variations, and progress against agreed efficiency targets. These reports can form the foundation for strategic decision-making and allow greater accuracy when budgeting energy spend.

Modern smart meters and online dashboards now make it possible to view real-time consumption, highlighting unexpected spikes or inefficiencies. Eliminating these can deliver instant returns. Reducing a site’s overnight load by just 20 kilowatts for ten idle hours each night can save £1000s each year. Replicate that across multiple sites and the savings quickly become significant.

Regular communication between the broker and client ensures that energy strategies evolve alongside business growth, production schedules, and investment plans. The best partnerships are collaborative and transparent, focused on long-term results rather than short-term contracts.

The Value of the Right Partner

Energy is no longer just an operating cost. It is a strategic variable that influences productivity, competitiveness, and sustainability. Partnering with SeeMore Energy provides not only procurement expertise but also insight, accountability, and a structured roadmap for achieving lower costs.

Our proactive, data-driven approach, powered by advanced analytics and real-time market insights, ensures that your business secures the most cost-effective contracts, avoids costly billing errors, and optimises network charges like kVA and TCR banding. Compliance improves, carbon reporting becomes simpler, and sustainability credentials can be strengthened for customers and investors alike.

Winning the energy battle requires expertise, visibility, and strategy. By aligning with the right partner, UK manufacturers can turn energy from a volatile expense into a controllable asset that drives both profitability and resilience in an increasingly uncertain marketplace.

Don’t let rising energy costs or market volatility hold your business back. SeeMore Energy offers a free, no-obligation consultation to analyse your current energy strategy and uncover immediate savings opportunities.

To explore how we can help you reduce your energy costs and future-proof your operations, please contact us at Manufacturing@seemoreenergy.co.uk or on 02477 981 051 and one of our expert team will be in touch.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News