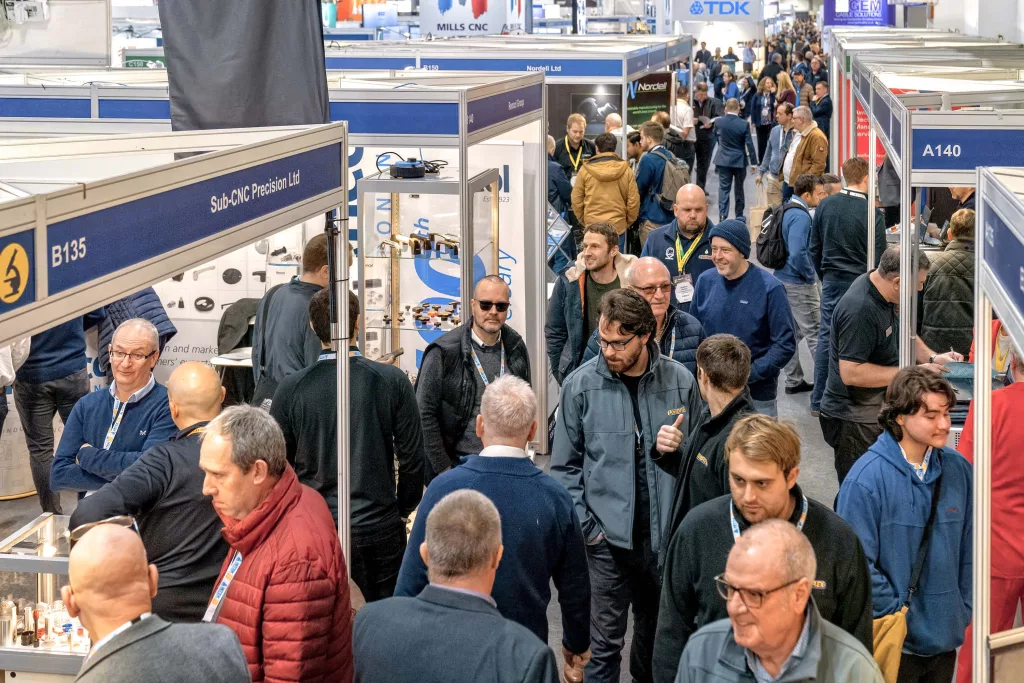

The UK’s most comprehensive and popular annual trade show, Southern Manufacturing & Electronics, will open its doors from 6th to 8th February 2024 at the Farnborough International Exhibition & Conference Centre. Many thousands of engineers will be eager to see all the latest in manufacturing

technology and service provision in the mechanical engineering and electrical/electronic sectors, which are represented in about equal measure.

This year the show is breaking new ground with the highest ever number of stand bookings by overseas companies. It has ensured that once again the event is a sell-out and elevated it further onto the international stage. It is a far cry from the early beginnings in 1997 when it was a small gathering of

regional engineering companies. The formula that has seen the exhibition rise to global success over the decades is the mixture under one roof of distinct yet complementary specialties. It means that people are able to satisfy multiple purchasing requirements in a time-efficient manner.

Although the industries and technologies are diverse, there are no barriers between the areas, allowing cross-over between the different disciplines. Visitors canvassed say it is a facet of the show that is especially useful, as it encourages a wide-ranging itinerary though the exhibition halls, leading to discovery of firms specialising in related technologies that would otherwise probably be missed. Technology Trails guide visitors around the event, grouping firms having expertise in particular areas.

Southern Manufacturing & Electronics is an event that attracts large and often multinational manufacturing companies, but it is also extremely accessible to small and medium size enterprises. The organisers operate a policy of open access, discouraging larger firms from dominating the space to the detriment of smaller vendors.

The mixture gives the show a vibrant atmosphere unlike that of others. Testament to this, and to the effectiveness of the show as a business forum, is the very high rate of return bookings. A large percentage of participants are regular returnees and many have been with the show since the start.

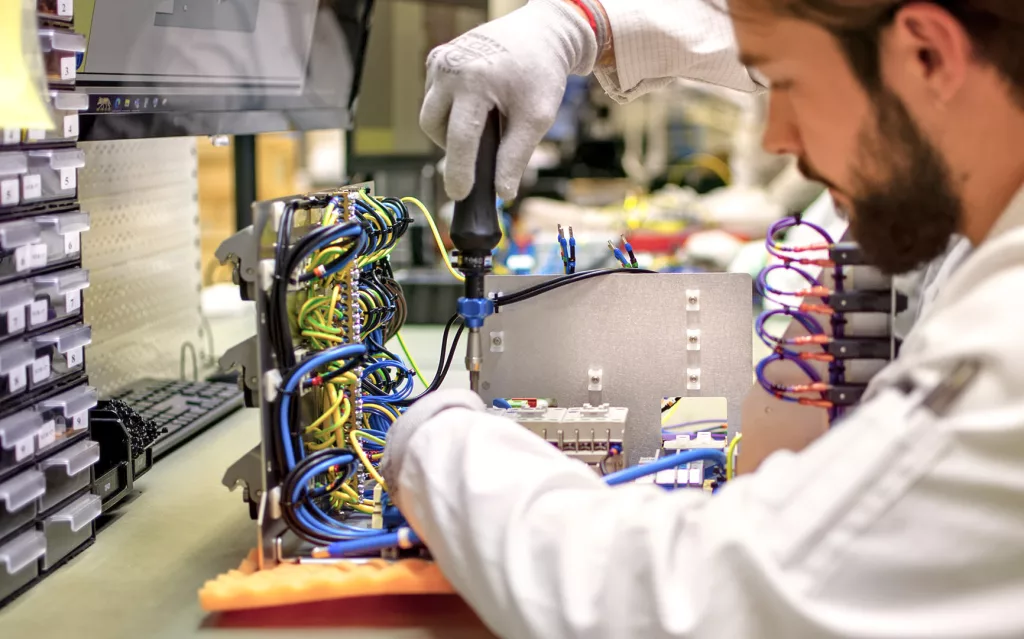

It is the perfect location to see all the latest in machine tools, tooling, workholding, 3D printing, and test, measurement, inspection and metrology equipment. There will be mechanical, electrical, electronic, electromechanical, hydraulic and pneumatic components and assemblies, surface mount

technology, PCBs, box build, connectors, cables, plastic injection and rubber moulding services, sensors, drives, encoders, fasteners, pressings, wireforms, springs, gaskets, and more. Subcontract services aimed at both the mechanical and electronic sectors will also be well represented.

Automation will feature prominently, driven by a skills shortage in Britain and across Europe. Manufacturing industry is also facing a battle to recover from the impacts of Brexit, supply chain disruptions, soaring energy costs and higher taxation. There will accordingly be an accent on technologies capable of mitigating their effects by raising efficiency and lowering costs, such as

robot and cobot machine tool tending, end-to-end digitalisation in Industry 4.0 environments, reshoring of production, and new technologies such as green energy and power-saving machinery.

Other diverse products and services on offer will encompass business and manufacturing software, production and planning aids, oil and coolant supply, workshop equipment, dust and fume extraction, humidity control, workplace storage systems, bespoke case and foam manufacture, plastic packaging,

hand tools, adhesives, waste removal and recycling, training, freight services and financial consultancy.

Running concurrently with the exhibition, over the three days there will be a series of free seminars to give visitors and exhibitors valuable learning opportunities, with a particular focus on the technical, managerial and environmental issues facing manufacturers today. The programme will be particularly strong this time.

For example, a seminar on design for additive manufacturing will be delivered by Stephen Graham, general manager of Nexus Industrial Memory. He will describe a project that is helping a 3D printing bureau to work with a customer’s engineering team to design collaboratively using a 3D whiteboard in Microsoft Teams. The environment combines generative design, build prep and powder bed fusion simulations in a two-way design review where everyone involved resolves issues together as they arise.

Going paperless on the shop floor has the power to connect workers, systems, tools and machines and has been proven to change the landscape of modern manufacturing. However, many companies fail to understand the potential of the digital tools at their disposal. Kalyna Spooner, sales coordinator at VKS, will take an overarching view of the digital factory and describe how to utilise to the best of its potential all that modern technology has to offer and what benefits to expect in a digital factory.

Ian Mercer from Merceric will explain how to manage hybrid working, a key outcome of the pandemic. It has resulted in the need for a paradigm shift in management, greater than any other in the last two centuries, and he says new management skills are needed to address the problems that have arisen.

In a second lecture, he will focus on change management based on Kotter’s eight-step model, which provides a framework for planning and implementing change initiatives. He will cover the amusingly-named ‘stages of grief’ that employees go through, helping managers to understand the seemingly

irrational responses of staff towards change and how to respond in a productive way.

Another seminar with an amusing approach but a serious underlying message will be the concept of ‘superheroes’ in any work environment – not just factories. Tim Scurlock, director of Applied Lean Consulting, will explore the legacy working procedures in businesses and propose measures to promote better methods to improve quality, increase throughput and shorten lead-times

using lean tools. Efficient companies run smoothly without key personnel having to go into panic mode every time a crisis occurs. If the success of a business relies on the urgent actions of a few people, that is a constraint and lean thinking can remove it.

Southern Manufacturing & Electronics 2024 will co-locate as usual with AutoAero, a specialist theme throughout the event devoted to automotive and aerospace engineering. The site is well connected by road and public transport links, car parking is free and there is a regular, complimentary bus service that runs between Farnborough’s railway stations and the show. Tickets, which are also free of charge, are available from www.industrysouth.co.uk

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News