Ecoclean – Energy efficiency and climate protection are key issues in the automotive industry. This does not only concern products but also their manufacture. To exploit the existing potential in the cleaning of engine components, a premium car manufacturer replaced the electric water heating system in its Austrian works with a heat pump. This has resulted in electricity savings of approx. 70 percent per year in this process step.

The energetic optimization of production lines and machinery for the manufacturing of core engine components like crankshafts and crankcases, cylinder heads and housings for the latest generation of electric drives has been on the agenda of BMW Group’s Steyr site for several years. This also includes the cleaning machines for these components. ‘To reduce energy consumption we have started with Ecoclean to equip the pumps of cleaning machines with variable frequency drives in 2016’ explains Gerhard Fuchs, person in charge of the processes and energy officer in the Steyr works. In the search for further ways to save energy, consumption measurements showed that the electrical heating systems of the cleaning machines running in three shift operation caused a high electricity consumption. Considerations on how energy could be saved in hot water generation resulted in the use of a heat pump. ‘I wanted to implement a pilot project to determine the energy savings potential we could achieve by replacing the previous electric heating system by a heat pump. Due to the excellent cooperation we have had with Ecoclean, I asked the company whether they would join us as general contractor. After they agreed, we chose a transfer cleaning machine of the manufacturer’, says Gerhard Fuchs.

Potential analysis by a neutral engineering office

To calculate the energy savings achievable by integrating a heat pump, a potential analysis was made first. The basis for it were the production, process and system data and previous energy consumption figures, as well as the modification concept prepared by Ecoclean. For reasons of neutrality we hired an independent engineering office for the analysis. They calculated savings of approximately 70 percent of the previous energy consumption.

Annual energy savings of 169 MWh

The solution is exactly tailored to the situation at BMW Steyr: On the roof of the transfer system there is a tank holding 2,000 litres of clean water that is supplied to the cleaning process at 56 °C. The required electrical heating system had a power drawal of 39 kW. Cooling of the vacuum pumps and control cabinet was effected by a cold water circuit. Cooling water is provided at a supply temperature of 16 °C and returns at a temperature of 22 °C. This ‘warm water’ serves as energy source. It is supplied to the heat pump (power drawal 11.2 kW) where it is heated to 65 °C. The heat transfer to the hot water supply of the cleaning machine is effected by a plate heat exchanger. A new circulating pump (power drawal 1.2 kW) delivers the heated process water to the hot water tank of the cleaning machine while a second new circulating pump (also with 1.2 kW power drawal) returns the water that has been cooled to 16 °C to the cold water circuit. This well-thought out solution reduces the energy consumption from 39 kW to 13.6 kW. With a defined production time of 5,760 hours per year this adds up to more than 146 MWh. Furthermore, another 23 MWh are saved in cold water generation since the cooling water now only needs to be cooled down from a much lower return temperature to the required supply temperature.

Quick modification without interruption of production

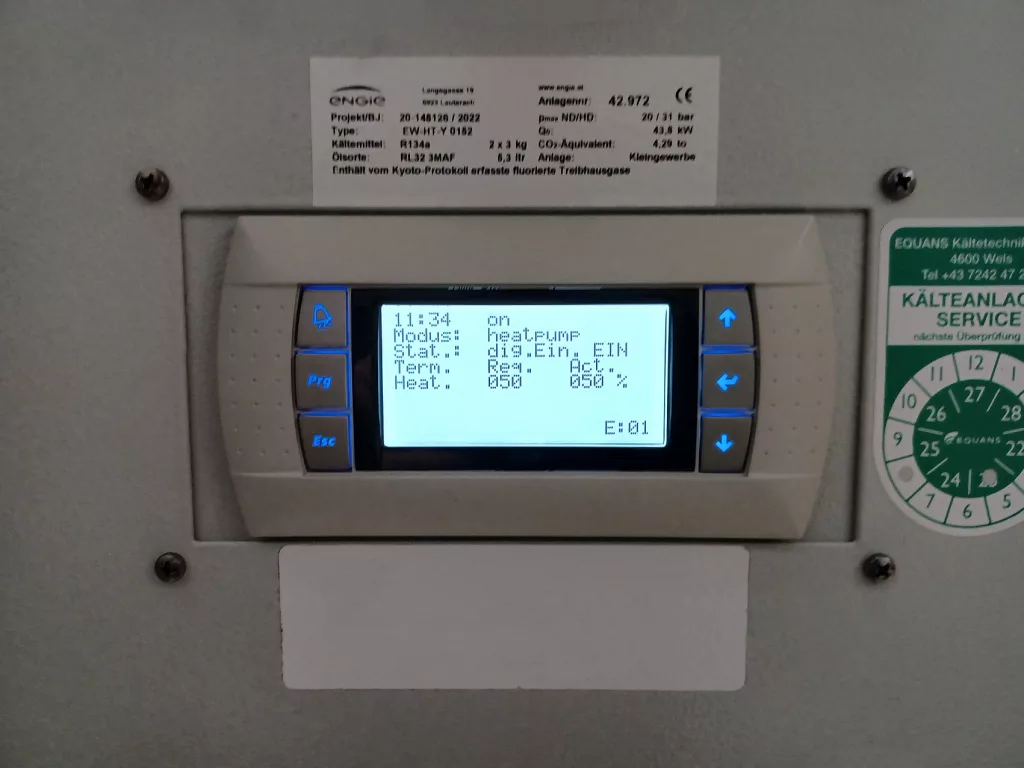

As the project was to be implemented without interruption of production operations, the modification job was carried out during a two week holiday in the summer of 2022. The heat pump, plate heat exchanger and the two new circulating pumps were installed on the shop floor near the machine, insulated and surrounded with guard fencing. The surface area required for this corresponds to approx. the size of two Euro pallets. In addition, the modification required four new pipes. Two of them connect the clean water tank on the machine to the plate heat exchanger. The two other pipes transport the warm water from the cooling circuit to the heat pump and return it after cooling. We integrated a display for temperature and flow monitoring. The company’s energy monitoring system includes an energy meter to verify the saved heating power. This monitoring as well as measurements made by the independent engineering office after completion of the project show that 100 percent of the predicted savings have been achieved.

CO2 footprint and operating cost reduction

Due to the saved current of a total of 169 MWh, the annual operating costs for cleaning have been reduced by approx. 19,000 Euros. In addition, In addition, significantly fewer CO2 emissions are emitted into the environment, in this case the savings amount to approx. 34 tons of CO2. ‘It has been a good decision to involve Ecoclean as prime contractor for energy-efficient projects. We are very happy with the results and their support, and will continue our cooperation’, concludes Gerhard Fuchs.

Contact: Ecoclean – Markus.Maybaum@ecoclean-group.net, www.ecoclean-group.net.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News