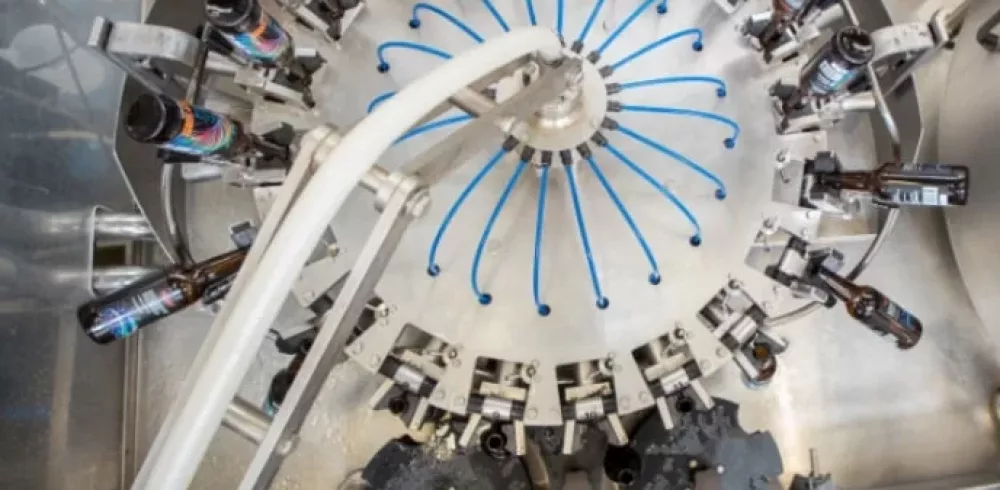

Hepworth Brewery, a leader in the UK independent brewing industry, adds Chart Industries’ (NYSE: GTLS) Earthly Lab’s CiCi® carbon capture technology to help them reduce their carbon dioxide (CO2) emissions and advance their goal of 85% carbon neutrality by 2025. Hepworth is also recycling the CO2, a key resource used in breweries, to also hedge against the CO2 shortages in the UK that have plagued the food and beverage industry since 2020 with the reduction of supply sources. While this marks the first installation of Earthly Labs small scale CO2 capture solution in Europe, Chart will accelerate its support of the multibillion carbon capture utilization and storage (CCUS) market with the support of the recent Howden acquisition headquartered in the UK.

“We are thrilled with our first European installation for small scale CO2 capture and look forward to supporting our customers with our expanded global network,” said Jill Evanko, CEO and President of Chart Industries.

“The primary focus of our investment is to heed the call to reduce greenhouse gas emissions and tackle the climate challenge. We have a deep commitment to sustainability, and this adds to our environmental stewardship roadmap,” said Andy Hepworth, Founder and Chairman of Hepworth. “However, the reality is the shortage of commercial CO2 supply is so prevalent, it is a risk to our industry. In fact, there were three days this year we did not have CO2 and without our own supply we simply could not produce beer.”

In addition to carbon capture, Hepworth has a portfolio of efforts to reduce their carbon and waste footprint through recovery, reuse and recycling. To reduce transportation emissions and make better beer, Hepworth relies on local ingredients supplied by the farmers of Sussex including organic barley from the Goodwood Estate in West Sussex and award-winning hops from Bodiam in East Sussex. In addition, they have implemented many energy efficiencies including double glazing, natural lighting, and solar power. Heat, a waste product from beer chillers, has been captured and completely heats the offices and visitor center with excess heat being used to preheat water for brewing. Furthermore, waste with higher protein levels is purified by anaerobic digester, producing new energy. Reed beds are used to recondition wastewater and feed it back into the river Arun, with necessary environmental approvals. Water with a high yeast level is taken off site for use as a soil conditioner. After use, Hepworth provides waste hops and spent grain to local farmers for use as animal feed.

“Hepworth’s origin story centers on preserving a rich brewing legacy and building on that through innovation to power a better future,” said Chart’s Earthly Labs President Amy George. “They are at the forefront of sustainability –carbon capture to waste water to anaerobic digesters. They are looking at problems as opportunities to make the Hepworth more resilient as they inspire customers in the UK for decades to come.”

Born out of a sense of preserving the rich brewing legacy, Hepworth’s was founded by its namesake Andy Hepworth and friends and family in 2000 as a response to the last brewery closing in Horsham. The brewery went on to build on brewing traditions, adding innovative production processes and beer styles. Since then, Hepworth has gone on to win numerous awards and has become a destination brand for locals and tourists alike at its brewery and two taprooms.

Europe has long been the seat of international climate initiatives and frameworks. In October 2017, the UK government announced its new approach to carbon capture, usage and storage (CCUS) called the Clean Growth Strategy. The approach was designed to enable the UK to become a global leader for CCUS and ensure that government has the option of deploying CCUS at scale during the 2030s. Chart’s Howden division, headquartered in the UK, will support the multibillion carbon capture market throughout Europe from sales, service, post-sale support and manufacturing. Earthly Labs will also add the Howden software monitoring to its own carbon capture platform, expanding the value of asset monitoring to carbon capture.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News