Tackling the aerospace backlog : Two of GKN’s top aerospace engineers reveal how the company is developing new manufacturing techniques to help tackle the industryâs growing backlog of orders. Helen Knight reports.

The aerospace industry has a velocity problem. With air traffic predicted to double in the next 15 years, and manufacturers already facing a backlog of aircraft orders worth more than one trillion dollars, finding new ways to speed up the production process has never been more important.

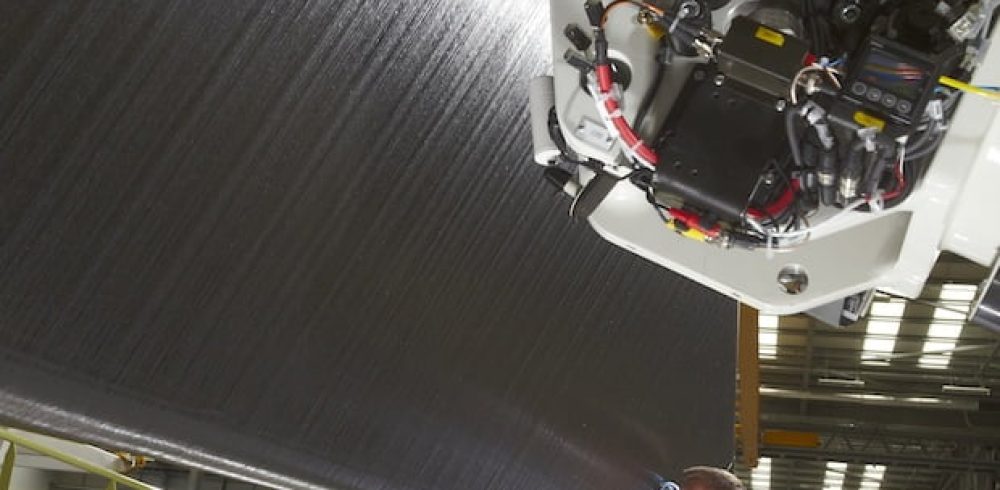

Inspection of automated fibre placement A350 XWB wing spar

Aircraft manufacturers are ramping up their production rates, obliging their suppliers to do the same. Airbus for example is planning to build 46 aircraft per month in 2016, up from 36 per month in 2010.

For companies like GKN Aerospace, one of the worldâs largest aircraft component manufacturers, this means developing new techniques to automate the manufacturing and assembly process, according to Craig Carr, manager of GKNâs Composites Research Centre on the Isle of Wight.

To this end, the company is leading a £30m research project aiming to further the development of promising wing design, manufacture and assembly technologies, in a bid to ready them for use on the production line. It also hopes to identify new composite and metallic technologies and manufacturing processes.

The 27-month Views programme (Validation and Integration of Manufacturing Enablers for Future Wing Structures), which also includes Bombardier Aerospace, Spirit AeroSystems and GE Aviation as well as nine UK universities and research centres, is being funded by Innovate UK, the government-backed agency previously known as the Technology Strategy Board.

It follows the success of a previous GKN-led project, the Structures Technology Maturity (STeM) programme, which developed processes to reduce the cost and time taken to manufacture and assemble a composite winglet by 20 percent. The £12m STeM programme proved so successful, particularly in the way in which the member companies all worked together, that it is now used as an example to other Innovate UK projects on how they should be run, said Carr, who led the effort.

âWhat we were looking at were projects that improved the way we bring components together,â said Carr. âSo we were looking at eliminating fasteners in a structure, and how best to bond components together so that we could improve the performance, and reduce the cost and ideally the weight of the components we are manufacturing.â

STEM winglet robotic assembly

Traditional assembly processes for composite wing tip structures involve fastening multiple parts to the upper and lower skins of the wing, said Carr. To speed up this process, the team designed what they call a waffle winglet, consisting of a composite sub-structure shaped like corrugated cardboard. They then bonded this waffle structure to the lower skin of the wing tip by heating them both in an autoclave, which causes the resins of both components to join together. âSo rather than having 15-20 different parts that needed to be brought together, we had just two: the upper skin, and the waffle that was co-cured to the lower skin,â said Carr.

As a result, fasteners were only required to connect the upper skin to the waffle structure, reducing many of the traditional assembly steps, he said. The wing skins themselves were also constructed using an automated deposition process known as automated fibre placement.

Overall, the team was able to use 50 percent fewer fasteners on the winglet, and spend 25 percent less time on each fastening. GKN Aerospace is now looking to develop the technique for the other wing tip structures it manufactures.

The development of advanced joining methods is extremely important to GKN, as the removal of fasteners can reduce costs significantly, both for themselves and for aircraft manufacturers, said Carr. âIf you have composite or metallic structures, and youâre able to bond them together in some way, then you donât need a whole system of drills, or even robotic drilling machines that you then have to fill again with a fastener, which is quite a wasteful process,â he said.

The team also produced a rib structure using linear friction welding, a technique in which one part is placed on top of another and then vibrated at high frequency, causing the two components to heat up and fuse together. Using this technique they were able to produce one of the largest welded structures ever built, said Carr.

Not only does this reduce even further the need for fasteners, but the technique produces far less waste than conventional manufacturing processes, in which a larger piece of material is machined down to the right size, said John Cornforth, head of technology at GKN Aerospace.

âThis is an approach we are developing in order to bring efficiencies into manufacturing,â he said. âWe call it near net shape, where you start with plates and small pieces, and then you find different ways of joining them together,â he said.

The curing and bonding technologies developed in STeM, alongside additional processes identified by the team, will now be progressed further in the Views project, in order to move them closer to production readiness. âWeâll be taking forward the co-curing and bonding technologies, and developing further the automated assembly and drilling processes that we still have to use,â said Carr.

Outside of the Views project, GKN Aerospace is also investigating the use of three-dimensional printing, or additive manufacturing, in which components are built up layer by layer. The company is working on research and development projects to progress the technology, as part of a company-wide strategic initiative, said Cornforth. âGKN in the broader sense is a business that spans automotive and aerospace, land systems, and powder metallurgy, and the company has an initiative in which it is trying to introduce a [3D printing] capability for all of those businesses,â he said.

The technology makes it possible to produce aerospace components in shapes that would not have been previously possible, or would have been too expensive to manufacture using conventional techniques.

As a result, GKN believes 3D printing will be of considerable importance to manufacturing in the near future, according to Cornforth. âWe see additive manufacturing as a major trend,â he said. âIt could be quite disruptive, in terms of some of the machining capabilities that exist in the world today, so weâre working very hard on that.â

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News