Filtrona Tapes is reporting heightened demand for its total tape solutions from the envelope mailer and box-making industries as they seek to enhance their returnable packaging capabilities.

The competitive landscape is becoming increasingly challenging with increased advertising costs, ever-growing customer expectations, and a greater focus on E-commerce delivery and returns sustainability.

Thanks to modern, intuitive applicator systems, clean opening systems, and value-adding products such as EASILINER, returnable packaging is now more accessible for brands and converters than ever. The heyday of single-trip packaging for eCommerce applications is over – and that’s one thing that won’t be returning.

“With many online retail outlets offering free standard delivery and returns, it’s easier than ever to change your heart after trying on your purchases,” said Global Sales Director Christopher Morgan. “As a result, innovative returnable packaging solutions are required to meet the needs of a global circular economy – and this approach is rapidly gaining legislative support.

“One in five buy with the intent to return, so reusable options, which aim to transform packaging from single-use to multi-use assets, are being implemented as a sustainable alternative.”

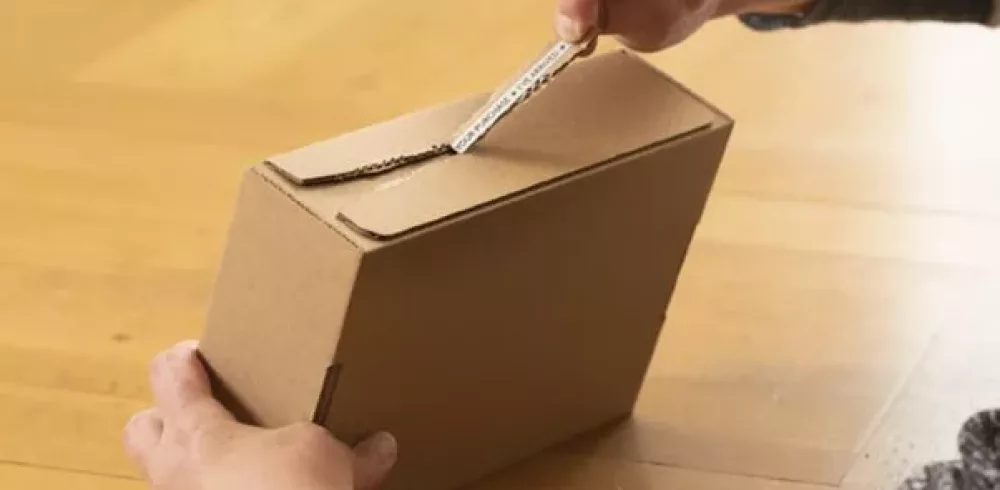

Ensuring packaging has an easy opening solution is critical to reduce opening frustrations and maintain the structural integrity of a pack that may be used for returning items. If a consumer has to destroy the packaging upon opening an item, the returns benefit is lost immediately. Filtrona Tapes’ Rippatape® product line opens corrugate and paper packaging cleanly, safely and without perforations.

With the packaging opened cleanly, if returns are needed, release liners offer a no-fuss, ready-to-use solution to reseal the packaging and allow hassle-free repackaging for the consumer. Filtrona Tapes provides a range of paper-based release liners under its EASILINER banner, which protect glue lines, allowing consumers to rip off the paper liner to reseal their packaging. Something as small as a glue strip and release liner can turn flexible packaging and corrugated packs into easy-return packaging with relatively little investment.

“Millions of shoppers, spurred on by the closure of physical stores during months of pandemic lockdowns, now regularly buy and return goods online,” added Morgan. “But sizing online is tricky; the choice is ever-expanding, and consumer preferences change at the drop of a hat.

“With many online retail outlets offering free standard delivery and returns, it’s easier than ever to change your heart after trying on your purchases—the result: a wasteful merry-go-round of returned goods.

“At Filtrona, we’ve turned our attention to packaging solutions we had never thought of. Working with our customers and partners, we want to bring innovations to market that help businesses expand their reuse portfolios.”

Returnable envelope mailers have two adhesive strips – one for shipping to the customer and a second one for the return trip. Deploying Rippatape® between the 2 sealing strips ensures clean, easy blade free access.With all three tapes now able to be applied simultaneously via an upgrade to the SF-AS DH1 applicator, , enabling returns ready packaging has never been easier.

Regarding boxes, Rippatape® tear strips and multiple strips of EASILINER make them easy to open for minimal damage and easy returns.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News