At FoodEx 2023, Stand G100, JentonDimaco will showcase its latest Veri-VIEW software that checks food labels against robust source data before any food packs leave the factory floor.

JentonDimaco will explain to visitors how this ‘belts & braces’ automated approach to label verification can accelerate the verification process, catch mis-labelled products early, enable product to be reworked and re-labelled, resulting in fewer costly and brand-damaging food Emergency Product Withdrawals (EPWs).

“Checking the image quality and presence of a printed label is essentially only half the story and could be futile and non-compliant. Particularly if the production and retailer source data that food labels are being checked against isn’t correct or the most up-to-date version,” emphasises Managing Director Dr Russell Sion.

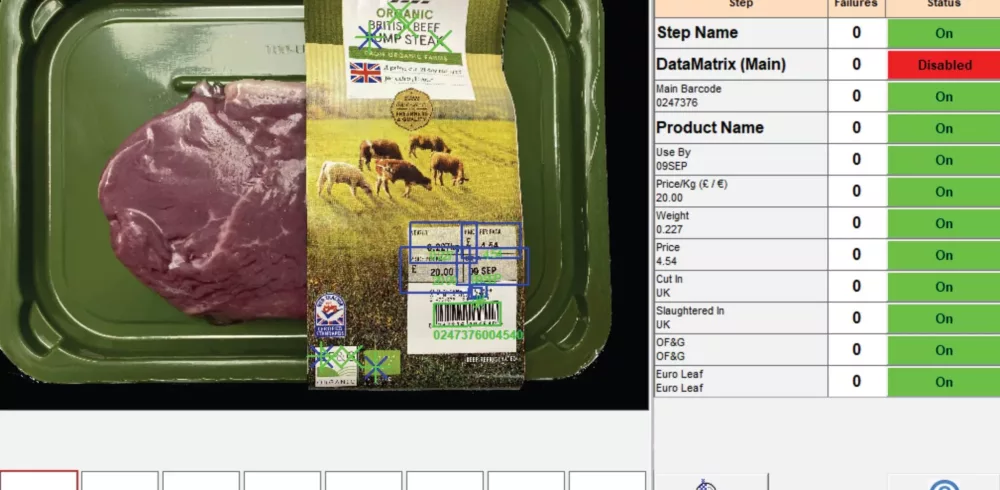

Mitigating the risk of human errors, the addition of Veri-VIEW software helps to ensure that all of the variable and non-variable label data matches up. Providing an instant overview of label integrity, Veri-VIEW captures in real-time, all the data generated by every Dimaco Veri-PACK system on the factory floor. Providing a complete overview from one convenient central display. Production and technical personnel get to see what’s happening as new data is issued, with the assurance that all actions are automatically recorded.

Putting this into context, this means that when a supermarket makes a label adjustment during the production run, for example to a price, the JentonDimaco Veri-CENTRAL server will pick this up instantly. This information is then automatically relayed to every Veri-PACK labelling system within seconds and the action taken documented on Veri-VIEW.

Russ expands: “JentonDimaco label verification systems are the most efficient way to authenticate all aspects of data and artwork on retail labels including price, barcodes, use-by dates, promotional labels and artwork revisions. All of this data is verified against a master specification held on the JentonDimaco Veri-CENTRAL server, which sources data from each food manufacturer’s MRP server or production spreadsheets.”

After biological contamination, label related defects are cited as the second most common cause behind costly and brand-damaging recalls and retailer returns.

Exceeding the label verification standards set by all UK retailers, come and learn how your food production site can introduce a more robust label verification system, reduce waste, address costly EPWs and meet future label compliance standards at FoodEx 2023, Stand G100.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News