Rising energy costs, high inflation and an acute shortage of skilled workers are putting UK manufacturers under enormous pressure. As evidenced from previous challenging economic times, those that typically come out the best, and in some cases even stronger, are those that are able to pivot and take proactive measures to protect their business. In uncertain times, it’s important to measure and improve your productivity and efficiency levels. OEE (Overall Equipment Effectiveness) is seen by the majority of manufacturers as the gold standard in productivity monitoring, taking into account performance, availability and quality. OEE identifies the percentage of manufacturing time that is productive. An OEE score of 100% means you are manufacturing only good parts (100% quality), as fast as possible (100% performance), with no downtime on the machine (100% availability).

Traditionally, OEE data has been captured manually which is labour and time-intensive and often inaccurate and out of date. A more practical and useful alternative is to look at the opportunity new technologies using Industry 4.0 methods can bring. For example, affordable machine monitoring platforms are now easy to install and require little upfront CAPEX investment. They can capture real-time data to generate accurate OEE reports and subsequently improve production efficiency.

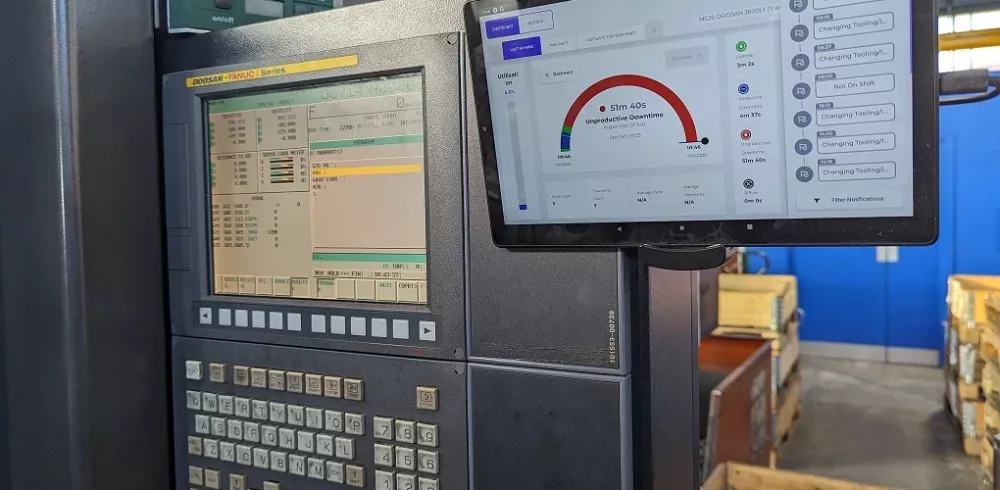

FourJaw Manufacturing Analytics has just released its next-generation machine data monitoring platform, incorporating real-time OEE functionality. FourJaw 2.1 is the latest edition of the award-winning cloud-based manufacturing analytics software which utilises plug-and-play hardware to capture the top causes of machine downtime, giving manufacturers real-time measurement and visibility of the efficiency of their factory floors to drive process improvement.

The technology harnesses Industry 4.0 principles to make it work with production machinery of any age, size or model. This enables both batch and production line manufacturers to use their machine data to make informed decisions to improve current production processes resulting in increased productivity, capacity and profitability.

Achieving greater efficiencies and productivity often relies on good communication throughout the business. The functionality of machine monitoring platforms such as FourJaw 2.1, which includes in-app messaging to improve communication between factory floor operatives and management, facilitates faster communication without taking operators away from their machines, and therefore quicker remedies to any problems, resulting in better teamwork and transparency across the business. The aim is to empower factory floor staff to get the support they need when they need it and to access feedback on the productivity of their machines in real-time.

Wherever you are on your OEE journey – and particularly when you are in the midst of an uncertain and difficult economic climate – deploying a reliable and accurate OEE machine monitoring platform will help you to minimise wasted costs and resources, and reach your OEE performance, availability and quality goals.

____

FourJaw is an easy-to-install OEE machine monitoring platform that can enable you to determine your machine’s availability and identify areas where performance can be improved, helping you on your journey to lean manufacturing in a difficult economic climate.

For more information visit www.fourjaw.com or call 0114 400 0158

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News