Renewable natural gas (RNG), solar, wind and other sustainable resources are at the core of decarbonisation and energy transition strategies. To effectively support their large-scale adoption, it is necessary to ensure dispatchable generation and predictable supply to the grid. Future-oriented energy storage plants that leverage cutting-edge industrial automation, such as digital twin technology, can succeed in this by taking advantage of accurate, real-time simulation models.

Alan Messenger, Sales Director at Optimal Industrial Automation, looks at how to support future energy security by enhancing energy storage with automated digital twins.

Renewable energy sources, such as RNG, provide multiple benefits. In addition to supporting ambitious decarbonisation and net zero goals, they also offer the most economical way to create a decentralised power system. This, in turn, can help achieve universal, reliable and affordable access to power.

For these reasons, the use of alternative energy sources is increasing in popularity, representing almost 11% of power generated globally and forming a major part of the energy mix in many counties1. For example, renewable energy use in Norway covered more than 60% of total consumption in 20182.

One of the key challenges that must be overcome to support the increasing adoption of renewable natural gas and other replenishable resources for power generation is balancing fluctuating electricity demands with the intermittent nature of some green sources. For example, to succeed in decarbonisation efforts and avoid any wastage, it is essential to prevent curtailment. This occurs when a power generation system is prevented from exporting to the grid, usually because of a temporary constraint caused by congestion, essentially wasting potential low-carbon energy supplies.

The importance of advanced energy storage solutions

To fully utilise generation capacity, robust, reliable and highly efficient energy storage solutions are required, as they can provide the level of flexibility needed to maintain stable and consistent supply to the grid. Strategies such as these can support peak shaving and load shifting activities.

Compressed-air energy storage (CAES) in its various thermo-mechanical forms, is among the most promising technologies available at a commercial scale for high-capacity energy management. By saving potential energy in the form of compressed air, these systems are able to generate large amounts of power on demand.

Also, apart from access to a cavern, CAES facilities are not dependant on specific geographies, unlike pumped hydropower, and their daily self-discharge is very low, making it possible to effectively keep the stored energy for long periods without any considerable losses. In addition, due to the well proven nature of the underlying equipment, CAES plants typically have a designed lifetime of over 40 years, which keeps the overall costs per unit of energy (or power), among the lowest for all available storage technologies.

To achieve these results, CAES facilities can utilise different configurations, one being the innovative liquid air energy storage method, which leverages thermo-mechanical principles to advance the benefits of CAES. In the liquid air variant, air is purified and cooled to its liquid state during the charge phase. It is then stored at cryogenic temperatures and low pressure in suitable tanks. When discharged, the liquid air is pumped to a high pressure, evaporated, and heated to expand the liquid air stream. The resulting high-pressure gas drives a set of turbines in a power recovery unit.

Liquid air energy storage is the way forward

The liquid air energy storage cycle described above utilises components that are commonly found in conventional power stations and industrial air separation plants. Therefore, they offer multiple advantages. Firstly, they are well-proven and broadly accepted. Secondly, this equipment is widely available to support commercial-scale facilities. Finally, they have well-understood maintenance requirements.

Furthermore, the use of liquid air energy storage systems leads to energy densities that can be up to 8.5 times higher than conventional compressed air alternatives3. Therefore it is possible to create compact plants that are more economical, efficient, easier to implement and suitable for sites with limited available space.

In addition, the power generation cycle eliminates the need for combustion and the associated carbon emissions while also supporting ‘cold recycle’ practices. Waste heat from the liquefier compressors is recovered within the process for highly efficient operations and the storage and recycling of thermal energy released during discharge can be used as part of a closed-loop system to support air liquification activities during charging.

Automating energy storage process control

A liquid air energy storage process offers per se unique financial and environmental benefits. Nonetheless, with temperatures ranging between -200 and +600 °C and pressures reaching up to 200 bar, small variations in these can impact performance significantly. This means that the optimum control of processing parameters throughout the different phases is key. This is essential to maintaining energy efficiency and low costs while maximising the end results.

By supporting real-time feedback and feedforward systems as well as remote monitoring, industrial automation technologies provide an ideal solution to consistently deliver peak performance and efficiency. More precisely, fully integrated automated process control provides a highly available, responsive and secure framework for monitoring and visualisation, trending and analysis as well as the management and synchronisation of all pieces of electro-mechanical equipment onsite.

By using this type of automated setup, liquid air energy storage plant operators can ensure the proper sequencing of all processes and promptly address any alarm to maximise uptime, ultimately delivering high efficiency and productivity. As a result, it is possible for facilities to realise dispatchable and predictable power distribution to the grid while also maintaining a low – or even net zero – carbon footprint.

However, having precise control over operations to ensure optimum operations requires an in-depth understanding of the process and the ways in which all components work together and influence each other. Only in this way it is possible to effectively regulate all activities. As liquid air energy storage facilities are relatively new, this insight may not be readily available to plant managers.

Leveraging digital twin technology

Having a flexible automation setup that can support liquid air energy storage plants while helping to develop process knowledge is a key resource. Moreover, the use of advanced data analytics can enable the creation of an accurate and precise process model known as a digital twin.

This offers a real-time virtual representation of a physical asset. It uses data generated by sensors on the system as inputs and produces predictions about future behaviours. It then turns this data into accurate, accessible and easily understandable information formats for immediate insights. As more data becomes available, the digital twin can be constantly updated to offer improved accuracy and additional capabilities. The most immediate benefit of a such framework is the ability to organise all process information and have a single, comprehensive process overview that allows for effective decision-making.

Digital twins empower operators to simulate different operating conditions and scenarios, evaluating the system’s limitations without the need to run these in the physical world. This, in turn, helps improve cost-effectiveness and safety. Consequently, a digital twin application that encompasses all stages of a liquid air energy storage plant is a key tool that can be used to enhance process modelling and understanding while also enabling agile operations and driving continuous improvements. Furthermore, these virtual representations can go even further, interacting with their physical counterparts as cyber-physical systems (CPSs) to create even more proactive and flexible setups.

To fully reap the benefits of the latest industrial automation solutions, such as advanced process control and digital twins, energy storage facilities should partner with an expert system integrator. This can address the specific needs of the sector and is equipped to support innovative processing methods and technologies, delivering futureproof, scalable solutions that can grow with a business as well as advance it.

A digital twin of the first full-scale UK liquid air energy storage facility

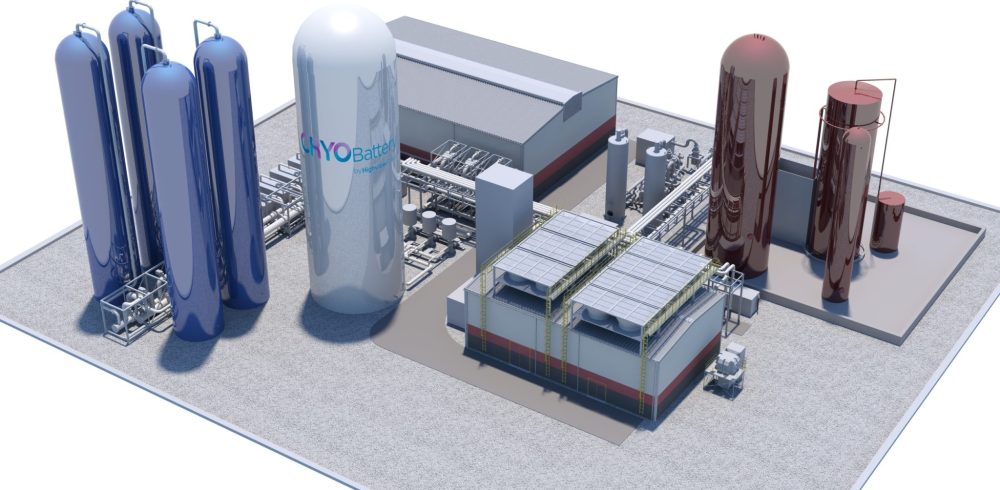

Highview Power, a global leader in long-duration energy storage solutions, is supporting the global adoption of advanced cryogenic plants with its proprietary liquid air energy storage technology. The company’s latest project is the construction of a 50 MW liquid air energy storage facility (with a minimum of 250MWh) in Carrington Village, Greater Manchester, UK.

Able to power approximately 200,000 homes for 6 hours a day, the plant will help balance the supply and demand for renewables. To ensure successful operations at this landmark facility, the company is collaborating closely with its automation and technology development partner, Optimal Industrial Automation.

The automation system integrator has been supporting Highview Power since the creation of the cryogenic energy storage specialist’s first pre-commercial scale demonstration plant at the Pilsworth Landfill facility in Bury, Greater Manchester. Since the automation requirements of this initial facility were unspecified, due to the unique nature of the technology, an automation specialist that could ‘handle the unknown’ and deliver a flexible solution was a must. Having already developed a proven system to address these challenges, starting with the instrumentation requirements and through to commissioning, Optimal was the obvious choice.

For its latest, larger project in Carrington, Highview Power was keen for the automated system to feature a digital twin of the liquid air energy storage facility for use in training and for marketing demonstrations. This would support the growth of good asset data, which is key to the continuous improvement of the process model and an increasingly detailed understanding. By doing so, the digital twin would ultimately support the optimisation of this and future plants as well as futureproofing energy storage operations, in line with the company’s digital transformation strategy.

To develop this cutting-edge solution, Optimal had to address a number of exacting requirements. Firstly, the team had to select heavy-duty instruments that could withstand the operating conditions at the liquid air energy storage plant. Secondly, it was essential to create an automated setup that would be extremely accurate and reliable in order to promptly identify and act upon any change in the key processing parameters, such as temperature and pressure, while maximising plant efficiency, performance and safety.

When looking at the parameters that the digital twin needed to account for, it was necessary to enable it to interface with advanced mathematical models and simulation software platforms in addition to the physical automation system. To address this level of complexity, providing a solution that could support multithreading and multiprocessing functions was crucial.

Thanks to its extensive expertise in building, integrating and optimising automation systems for challenging and highly regulated industries, Optimal has a unique knowledge of a wide range of vendors’ portfolios as well as the most suitable products available on the market. With this insight, the company was able to leverage high-performance components featuring world-class redundancy, availability, fault-tolerance as well as maximum connectivity.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News