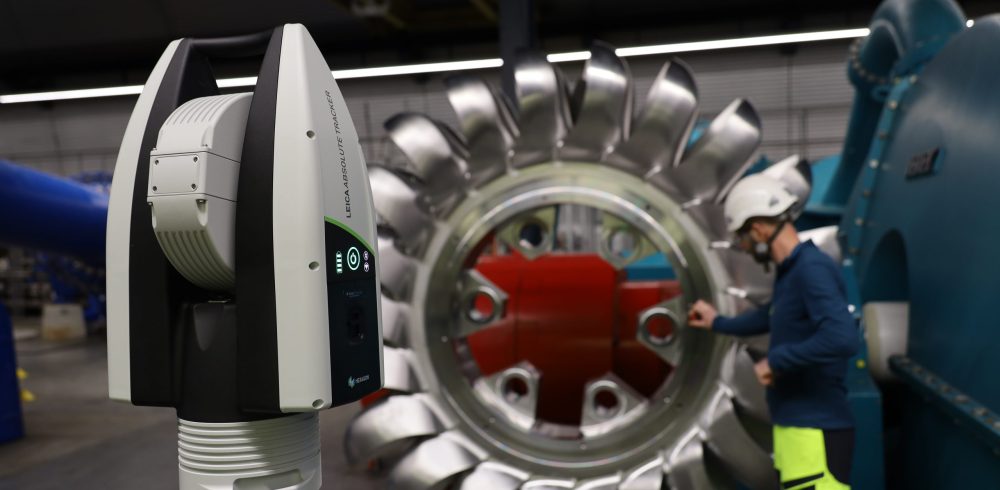

Hexagon’s Manufacturing Intelligence division has announced the launch of the Leica Absolute Tracker AT500 and accompanying B-Probeplus, the company’s latest portable 3D laser tracker system. Succeeding Hexagon’s popular AT400 series range of 3D laser trackers, the AT500 brings improved performance to both reflector and probing measurement. A true ‘measure anywhere’ system, the AT500’s portability and versatility is powered by a new integrated controller design, full IP54-rated environmental protection and an expanded operating temperature range.

The AT500 has been designed as the most portable and robust laser tracker in Hexagon’s range. A number of features contribute to extremely fast setup times, including the system’s built-in controller unit, a first for an Absolute Tracker. This new design is a big step forward in portability, with cabling minimised and setup reduced to an essentially plug-and-play concept. Alongside the platform having no need for levelling or initialising on a reflector before measurement begins, this development allows the system to deliver significant overall productivity improvements and reduced time-to-result.

This next-generation laser tracker platform also delivers a revolution in probing functionality with the new B-Probeplus wireless handheld probing device. An increased tilting angle and working volume makes the probe comfortable to use and easy to target, with real-time connection feedback displayed directly on the probe unit’s live display read out, helping to ensure data points are measured correctly on the first click. And all that comes with accuracy certification in line with ISO 10360-10 specifications.

“The AT403 and its predecessors represented a ground-breaking laser tracker platform that has driven metrology-grade measurement into completely new areas over the last decade,” says Rodrigo Alfaia, Absolute Tracker Product Manager at Hexagon. “With the AT500, we wanted to continue that story while delivering improvements we know our customers have been asking for. Making our probe easier to use has been a key target for us, and with the B-Probeplus I believe we really have a system that can deliver huge productivity improvements and change the way people measure in difficult environments. The live measurement feedback on the probe makes such a big difference to the systems usability – taking a measurement has become so much easier with this new generation.”

Further to this, an expanded operating temperature range of -15 to 50°C will allow the AT500 to deliver accurate results whether aligning mountaintop radio dishes or inspecting large workpieces in foundries. Taken together with a market-leading measurement volume up to 320 metres in diameter and the essential IP54-rated ingress protection – unique to the AT500 on the laser tracker market – the AT500 stands out as the most robust measurement system for challenging environments that go beyond the bounds of everyday manufacturing applications.

Integration with Hexagon’s HxGN SFx | Asset Management solution adds to the reliability and portability of the AT500 and makes the system even more capable of living up to its ‘measure anywhere’ credentials. It allows the system to be monitored and managed remotely, facilitating collaborative team structures. All team members can easily keep an overview of the location of all devices in their fleet – whether laser tracker, CMM or portable measuring arm – and ensure all are up to date and properly calibrated and certified, even receiving alerts in the case of shock events or status changes.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News