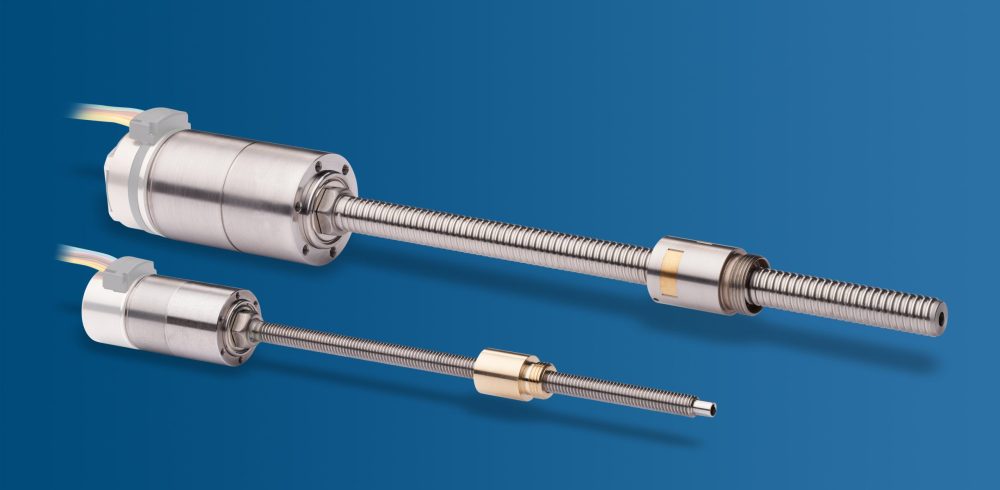

Small DC motor supplier Electro Mechanical Systems (EMS) Ltd has expanded its offering of FAULHABER linear actuators with the new L series. The 22L and 32L linear actuators are well suited for a broad range of applications including industrial automation, optics and photonics.

The new family of linear actuators is designed for high performance in compact dimensions, and can support both large input speed and high output force. A large number of uniformly distributed reduction ratios are available to enable the most appropriate configuration for various force or speed operating points, as required by the given application.

The L series grants design engineers a high degree of flexibility with a wide variety of product options, including screw type and length, nut type and length, as well as different motor cable or terminals orientation when integrating the combination unit inside the application. Various flange and nut configurations are available to match different ambient conditions and make mechanical integration inside applications faster and smoother.

“The FAULHABER L series offers a very robust design,” explained Dave Walsha, sales manager at EMS. “It can be combined with a wide portfolio of combinable motors such as FAULHABER DC motors, 4-pole and 2-pole brushless motors or stepper motors.

“The 22L and 32L are available with lead screws and additionally as ball screw versions in two accuracy options. The primary difference is the rolling movement of the ball screw nut, which eliminates the sliding friction that’s typical of lead screws, resulting in a very high efficiency. Design engineers should consider the characteristics of each of the available screw type to find the best match for their particular application.

“As the sole UK provider of FAULHABER products, this new linear actuator series adds to the growing range of FAULHABER products that we offer our customers. The flexibility and high performance of the 22L and 32L linear actuators makes them well suited to various applications including robotics, industrial machines and laboratory equipment. Customer specific modifications are also possible in order to enhance particular performance parameters to fulfil specific needs, like accuracy.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News