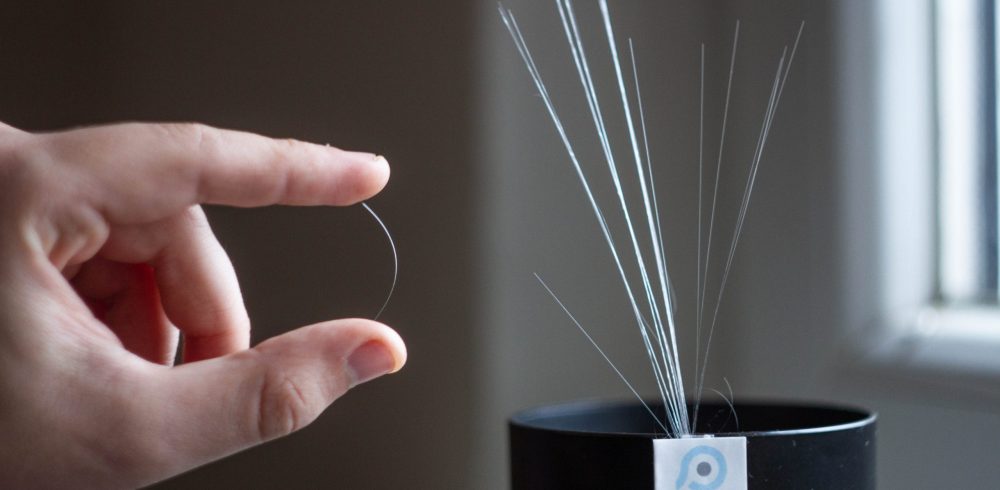

RVmagnetics introduces the future of wireless measuring with their smallest passive sensor in the world, called MicroWire. With no contact required – this sensor measures pressure, temperature, magnetic field directly and torsion, stress, bending, flow, etc. indirectly. It is thin, elastic, and as miniature as it gets.

The initial added value from the solution is the possibility to replace multiple sensor interfaces with one, while also receiving real-time physical data from otherwise inaccessible locations. The boost in the fields of predictive maintenance, machine learning and AI, is only as good as the data, thus, receiving continuous, precise, valuable information on what happens in a local environment of an application – is a priority that now does not need to be overlooked.

Passive measuring is based on MicroWire technology and magnetic fields (no direct wiring to power the sensor needed) Sensors can withstand harsh acidic and alkaline environments, provide accurate data for a period longer than a lifetime and survive high temperatures without losing its accuracy. Noisy electro-magnetic environments do not harm the measurements either.

RVmagnetics offers the technology and R&D based on the developed product – MicroWire sensors, at the same time, it is no off-the-shelf solution. Sensors and the sensing technology are designed to meet the needs of a specific application, calibrated for desired ranges and accuracy, and given the size of the technology – it can be embedded to almost any material (carbon/glass composites, ceramics, plastics, concrete, steel and even human tissue!) without affecting its property or causing defects, neither bringing a need to change the existing industrial design.

Microwire sensors find their use in a wide range of applications and industries. Since 2015 RVmagnetics has been closely working with European, US and Asian customers on customization projects. Current use cases involve industrial manufacturing, civil engineering, transportation and IoT areas.

The MicroWire sensors are best suited for applications where no other sensor could achieve the specific needs of the client, in other words we are able to sense unsensible, from otherwise inaccessible locations. Some specific areas of increased added value due to using the MicroWire sensors include:

- Real-time Non destructive testing

- Structural Health Monitoring with boosted capacities

- Enabling precise Preventive and Predictive Maintenance

- reducing the claim costs,

- increased safety, efficiency and effectiveness of an application or production process

- simply predict delamination, crack, material defects

- recognize original products from counterfeits