Linear guides are a must in any industrial setting, to help move equipment and objects on the production line. Marcus Schneck, CEO of norelem explains what to consider when specifying a linear guide.

When it comes to manufacturing, linearity is crucial. In demanding applications such as factory automation, systems must have absolute linearity as production lines depend on machinery that will reliably move along a pre-determined axis, over and over again.

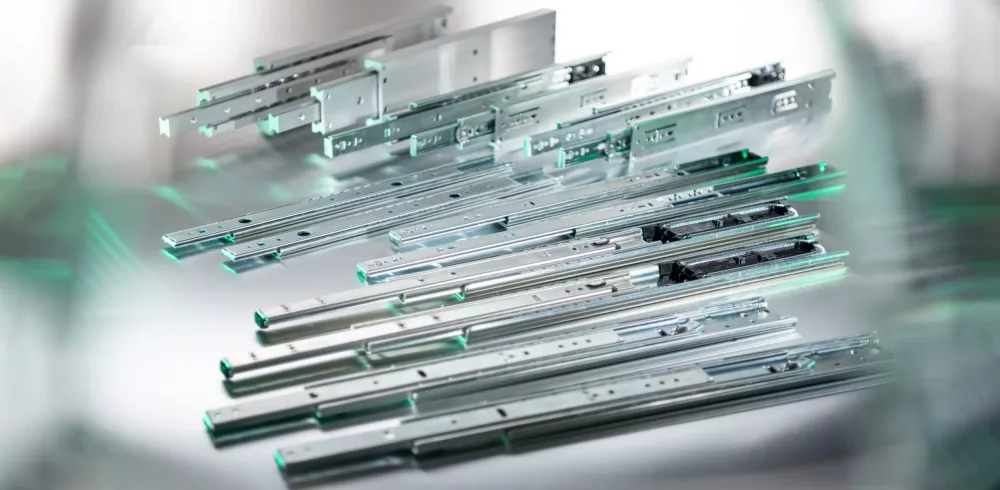

To achieve that quality of linear transfer, design engineers use linear guides. In principle, it’s the same technology that helps people around the world to open clothes drawers reliably, day after day. Yet the stakes are considerably higher in a factory setting. A linear guide needs to be strong and frictionless, maintain its performance over thousands, if not millions, of repeatable movements, and it must withstand forces without becoming deformed.

Which linear guide is right for you?

There are two main types of linear guide system, each with its particular characteristics.

Slide guides

Slide guides are linear guides in which the individual linear guide elements are not separated by rolling elements. Linear slide guide systems include the dovetail slide from norelem, which prevents a guide element from lifting during rotational movements, well-suited for absorbing and damping shocks and vibrations.

Telescopic slides are another option – norelem’s range provides effective movement for payloads from 10 kg to 450 kg and help reduce friction, noise, and the need for maintenance.

Slide rails are manufactured in steel as standard but are also available in stainless steel or aluminium.

Roller guides

In contrast, roller guides are based on a rotational mechanism, whereby rollers or ball bearings are rotated between two moving elements.

A rolling element retainer (such as a roller chain) keeps the rolling element in control and ensures that the guide runs as quietly as possible. Roller guides include profile guide rails and linear ball bearings.

Roller guide systems from norelem comprise guide rails in a variety of lengths that can operate with static loads of up to 5,500 N and dynamic loads up to 12,280 N.

Another type of roller guide relates to those which have recirculation rolling elements. Rolling elements recirculate within the linear block and move with the block instead of separately, akin to the tracks of a tank.

Choosing linear systems from norelem

At norelem, we have extensive experience in helping customers to choose the right linear guide system and our linear guides are used in many industries from packaging and medical technology through to factory automation.

____

To learn more about selecting the right linear system from norelem, please visit www.norelem.co.uk

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News