Automation post-Covid : The world is a different place since Covid-19 took hold. Families are communicating in a different way, travel has come to a stop and workplaces have had to change the way they operate. This of course extends heavily to the manufacturing industry.

Whereas many businesses have been able to adopt a remote way of working, the same cannot be said for component manufacturing. Whilst there were no people in the factories, business as usual came to a standstill. This has raised the profile of automation and how it can lend a helping hand to component manufacturers struggling to cope with the impact of this pandemic. Mills CNC & Doosan Robotics explain.

How can component manufacturers remain productive and profitable right now?

The answer is automation, and specifically robotics. Robots in manufacturing take on repetitive tasks with unparalleled speed and accuracy, leaving the job to get done with minimal man-power. This enables employees to focus on innovation and efficiency in a time when it is potentially needed most.

Prior to making any investment in robotics however, manufacturers need to make some fundamental decisions. One of the most important decisions is which type of robotic system will be right for them – industrial or collaborative? Peter McCullough, Product Manager at Doosan Robotics explains.

“In the post-pandemic world, manufacturers across all industries and sectors will no doubt be now beginning to explore the potential or automation and robotics within their businesses and whether they are an investment worth implementing. If and when they do make this decision, they will need to decide which type of robot is right for their operation and application; industrial or collaborative?

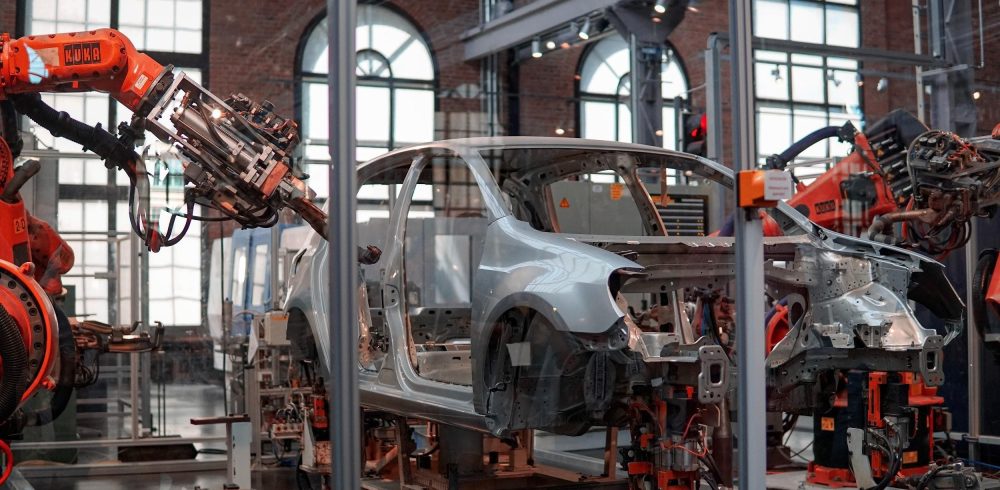

Let’s start with industrial robots. They are what most people will envision when they think of a robot on the shop floor; a big, heavy robot caged off toiling away, welding car chassis after car chassis 24/7 with not a worker in sight. These industrial robots complete repetitive and potentially dangerous tasks more quickly and accurately than a human employee ever could.

Collaborative robots, otherwise known as cobots, are a more recent development. These are robots designed to work alongside humans as opposed to replacing them. Like their industrial counterparts, cobots are designed to also perform these repetitive, error-prone tasks. Before the pandemic, it was estimated that cobots will comprise 34% of total robot sales by 2025.

So, which is best?

Understanding the strengths and limitations of both robot types is critical to chart a successful future. Choosing the wrong type can have a negative impact on future growth and can wind up being expensive.

One of the main advantages of industrial robotics is the speed in which they can perform complex tasks, and the payloads that they can handle. Both exceed that of cobots. Industrial robots are often integrated into more specialised manufacturing systems than cobots are, so they can deliver significant productivity gains.

However, because of the speed and force provided by industrial robots, substantial safety systems are needed to ensure that safety is maintained. With this in mind, the integration of powerful systems and the safeguards required come with a higher price tag than cobots.

Cobots operate at lower speeds and payloads than industrial robots. Their relatively low cost, inherent safety and flexibility, easy integration and collaborative nature means that they have the potential to deliver significant productivity improvements and a fast return on investment.

The cobot sector has seen a lot of innovation, not just from system manufacturers but also from accessory software and end-of-arm tooling suppliers, which has widened their appeal and application potential. The capability and acceptance of cobots is quite clearly increasing, and as countries emerge from the coronavirus lockdown and work restrictions, it’s likely that the use of this technology will grow exponentially.

When determining whether an industrial robot or collaborative robot is best for your manufacturing operations, the first step is to determine exactly what you want to accomplish. Is it increased production and input? Increased worker safety? Reduced scrap levels? Where do you intend to deploy your automation system?

Next, talk to organisations and experts who can help you realise your objectives and offer sound and insightful advice before undertaking an audit to see which robot solution makes the best financial and operational sense for your needs – now and in the future.”

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News