Onshoring: Should manufacturers bring business closer to home? : With Brexit dominating the thoughts of supply chain leaders and the C-suite, manufacturers have been looking at bringing work back into the UK. In doing so, the term “onshoring” is coming into play.

Here, I’ll share the reasons why you should to consider it as part of your business strategy and the role that Industry 4.0 and technology could play.

Why onshoring?

Offshoring has been a popular strategy for many manufactures for a number of years, with many businesses choosing to offshore manufacturing to reduce operating expenses and create high-quality products at reduced rates.

Although this is sometimes viewed negatively as it’s perceived to increase unemployment in the home country, it can be of value to economies both at home and abroad.

But with expanding overseas wage bills, for some businesses it’s becoming a better option to bring manufacturing back home.

Although onshoring also happens in other industries, it’s a growing trend in manufacturing due to a domestic demand for goods such as machinery, which is usually assembled close to final demand.

Five reasons why you should consider an onshoring strategy

- Lowering costs

As overseas economies develop and tax conditions change, wages, labour, raw materials and shipping costs could increase in price, which makes it less profitable for your business to employ people and conduct business overseas.

- Increased agility

Although technology can mitigate this, if you are closer to your customers, you can create shorter supply chains and lead times. Suppliers, manufacturers and distributors could have a closer relationship without the challenge of dealing with long distances.

- Predictable supply chains and settled inventory levels

If suppliers are far away, there is more uncertainty on delivery, meaning inventory levels may need to be higher in case of unforeseen disruptions.

- Higher quality

The UK has a long and well-deserved reputation for quality, with globally recognised systems and quality standards.

- Skilled talent

Closer to home, it may be easier for you to employ the skilled talent required to take advantage of the innovation and technology needed to increase profitability and efficiency.

Brexit acts as a catalyst

In 2017, a year after the UK referendum where the UK voted to leave the European Union (EU), the Chartered Institute of Procurement and Supply found that 32% of UK businesses that worked with suppliers on the continent were actively looking for alternative suppliers based in the UK, as a response to Brexit.

In Europe, it was a similar state of affairs, with 45% of EU businesses working with UK suppliers looking for local replacements.

Thinking about onshoring? Six questions to consider

According to the Make UK’s Brexit Toolkit, there are a number of questions that your business should consider if you’re thinking about bringing manufacturing home.

- How dependent are your customers on “just-in-time” manufacturing (which aligns raw material orders from suppliers directly with production schedules) and guaranteed delivery schedules?

- What tariff levels would your UK customers have to pay or absorb on EU-produced goods if the UK reverted to a World Trade Organisation (WTO) regime?

- What cost, regulatory and other advantages could your firm generate over foreign-based competitors?

- How long would it take you to establish a UK production facility? Could you stock inventory in warehouses in the interim to guarantee delivery?

- Could a network of European warehouses to hold inventory make UK production more feasible?

- Financially, what would a reversion to the pound’s previous strength do to the viability of UK plants? And what would that look like after the imposition of manufacturing tariffs?

In the end, you should choose a strategy based on what makes sense for your supply chain.

If new trade agreements disrupt or alter supplier networks and sources of supply, then it may be time to hunt for new suppliers or partner wherever be – both domestically and internationally.

Why technology and Industry 4.0 matters

It may be Industry 4.0 that drives the future, as technology will make a massive difference to complex supply chains.

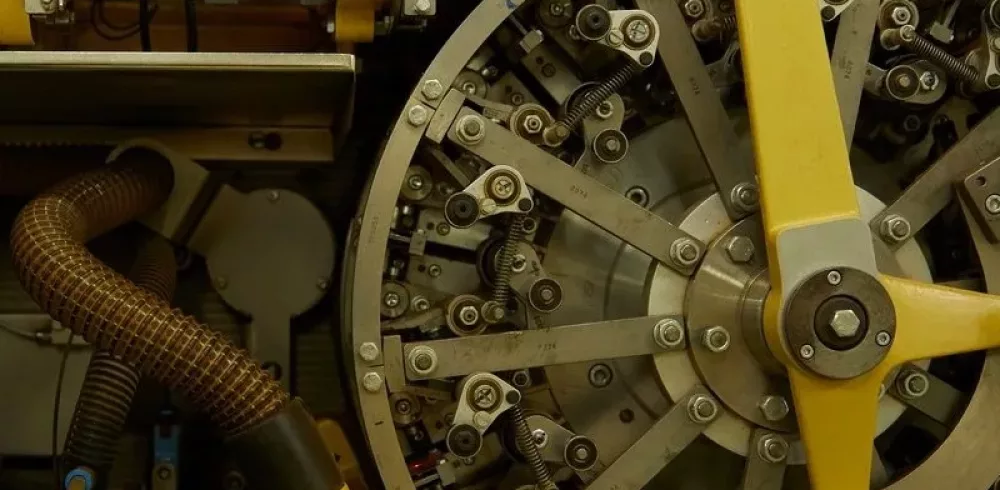

Through Industry 4.0 technologies such as automation, analytics and robotics, the very nature of factories is changing, which means it’s now possible to bring production back onshore instead of having to rely on labour-heavy work overseas.

For example, 3D printing or additive manufacturing allows businesses to create a greater variety of personalised products, speeding up time-to-market and making supply chains shorter, flexible and cost-efficient.

Having flexible supply chains means you can engage and disengage at will with certain suppliers from their local base of operations, manufacture from point of demand, and protect your intellectual property.

What manufacturers need to do now

In general, you should:

- Look at the strategic business reasons as to why onshoring could be attractive

- Ask questions about whether onshoring would be cheaper and more cost-effective than offshoring

- Consider whether the service quality benefits would justify such a move.

With offshoring, you might have seen an increase in overseas labour costs and management overheads. This could make onshoring look like a more attractive option.

Your firm might also look upon onshoring as a PR benefit, with a positive story to tell around creating jobs in your home country and offering local, high-quality products.

What you do need to do is develop a thorough analysis and quantification of the value generated in context of the possible risks and costs.

Other questions you could ask yourself are:

- Will the improvement in productivity outweigh the costs of onshoring?

- Will you be able to hire the skilled talent needed in your home country without breaking the bank? How can you keep them satisfied in terms of salaries and benefits?

- Could onshoring result in increased revenue and cost reductions in other areas of the business such as finance, sales and marketing?

- What are the one-time transition and ongoing costs of a onshoring project?

- Which locations would you be looking at and what is the quality of nearby graduates in terms of the skills you might need in the future?

Deciding whether to onshore or offshore won’t be a simple or quick decision but, with increasing regulatory pressures, it’s a question you might need to ask yourself as a manufacturer.

Make sure you keep line of sight on the big question – what is it about onshoring that meets your business needs?

Editor’s note: This article was first published in June 2019 and has been updated for relevance.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News