Until recently, the Industrial Revolution was largely associated with drastic engineering efforts that transformed Britain’s industry. Two centuries later, we are experiencing another shift in global manufacturing, the Fourth Industrial Revolution (4IR). Nigel Smith, managing director of industrial robot distributor TM Robotics, explains how Britain can reclaim the robotics revolution with simplified robot programming.

According to the International Federation of Robotics (IFR), Europe is the second largest market for industrial robot sales. Purchasing 56,000 units in total in 2017, Europe reached a new peak for robot sales for the third year in a row. That said, much of this deployment was attributed to Germany, so where does this leave us Brits?

Initiatives for digitalisation

Britain is no stranger to the Fourth Industrial Revolution, Industry 4.0 or whatever you wish to call today’s changes in manufacturing. In October 2017, the British Government announced its first major initiative to improve digitalisation in manufacturing, the Made Smarterreview.

Made Smarter called to boost productivity by encouraging manufacturers to embrace industrial digitalisation technologies (IDTs) — which includes robotics, automation and intelligent control software. The review suggested that a greater uptake of these technologies could create 175,000 new jobs in the next decade, because of a 25 per cent productivity boost in the sector.

Efforts of the Made Smarter review were bolstered in January 2018, when the World Economic Forum (WEF) in Davos released its first ‘Readiness for the Future of Production Report’. The report outlined how well-positioned economies are to benefit from Industry 4.0 technologies. The United Kingdom claimed a space in the top 25.

However, six months later in June 2018, the initial findings of the IFR’s World Robotics Report 2018 suggest that as it currently stands, the same nations are still leading robot sales. Germany has remained Europe’s forerunner with a total of 22,000 robot units sold. To put that into perspective, that represents over a third of Europe’s total robot purchases.

Much of this success may be due to Germany’s booming automotive industry, where manufacturers have long used six-axis robots in their production. Looking to the future, increasing the volume of robot deployment in Britain will rely on tapping into new markets by introducing small to medium-sized companies to automation.

Simplified programming

To reach this market, industrial robots must become more accessible, in relation to both cost and user experience. According to TM Robotics’ Global Robotics Report 2018, simple programming was one of the most important features for end-users when choosing a robot. In fact, 79 per cent of respondents named this as a top five consideration.

Currently, there are over 1,500 different programming languages in the world. Even for the most proficient robot engineer, learning every potential robot programming language is an impossible and impractical task. For new automation users, such as the small to medium-sized market, this can be incredibly daunting.

BASIC and Pascal are the basis of several industrial robot languages and tend to be the first any budding robot programmer begins to learn. BASIC, standing for Beginners All-Purpose Symbolic Instruction Code, is relatively simple, but can also be considered outdated for today’s demanding robotic applications.

Simple programming may be a top priority, but today’s end users also don’t want to compromise on robot ability — particularly for their first robotic investment. Therefore, a balance needs to be struck. Toshiba Machine’s controllers, for example, are programmed in SCOL. This is a programming language that is similar to BASIC, but with more advanced features.

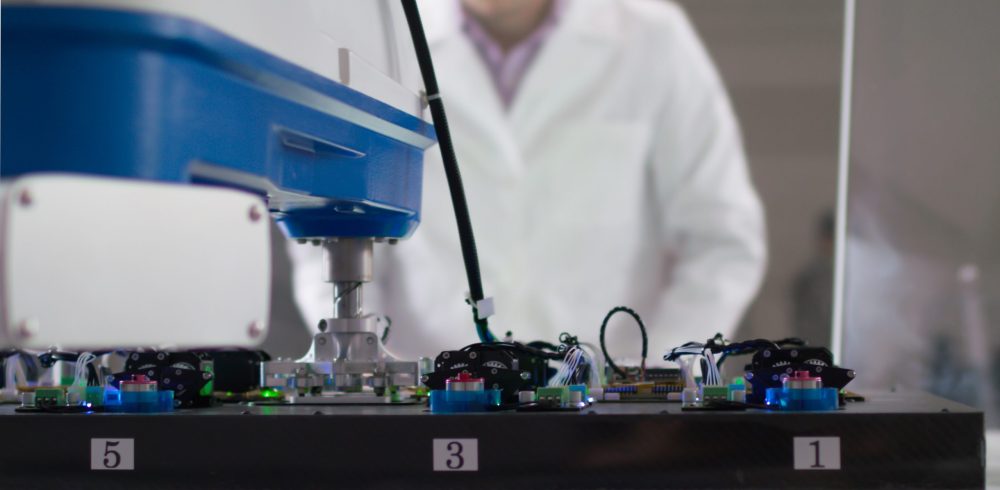

In fact, Toshiba Machine’s latest robot programming software, TSAssist, has been designed around usability. By opting for intuitive screen design and customisable operator panels, beginners find it easy to understand. TSAssist is compatible with any of TM Robotics’ industrial robots, including the extensive SCARA, Cartesian and six-axis ranges.

To cobot, or not

Growing demand for easily programmable robots is also evident in the rapid increase in sales of collaborative models — robots that can work without protective barriers between machine and employee. Collaborative robots, or cobots, currently account for 3 per cent of the total robotics market, but this figure is expected to reach 34 per cent by 2025.

These machines have been marketed as easy to program, but despite this, they should not be considered as a total alternative to traditional industrial robots. While cobots do boast some impressive responsive features, these machines generally cannot tackle the dangerous, repetitive and heavy-duty tasks usually associated with industrial robots — and this is something that new automation users aren’t always aware of.

In fact, 55 per cent of respondents to the Global Robotics Report do not believe that cobot technology is advanced enough to deliver the performance required for manufacturing, and a further 25 per cent were unsure of their capabilities.

To encourage investment from small and medium-sized businesses, robot manufacturers must ensure their machines are easy to program and don’t intimidate potential automation users. What’s more, unlike the large-scale automotive manufacturers of Germany, Britain’s robot customers may require more consultation and guidance to choose which robot is right for them — a cobot, or not.

The IFR predicts that the world will experience a further robotics boom in 2019, with an estimated 2.6 million robot units set to be deployed. Regardless of the initiatives and investments in place to encourage Britain to embrace robotics, efforts must begin with robotics manufacturers themselves. Simplified robot programming is key.