Ishida Europe has extended its range of application-specific Sector Solutions multihead weighers with the introduction of models designed to handle a variety of hardware products such as nuts, bolts, screws and plastic parts.

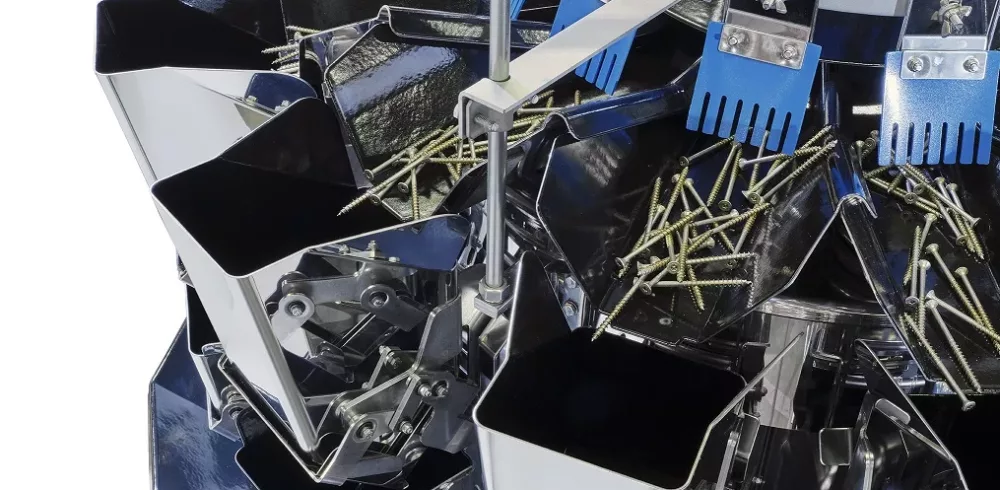

The new 10 and 14 head weighers, based on Ishida’s proven RVE series, incorporate a number of specialist features for the accurate and efficient weighing of varying shapes, sizes and piece weights at different target weights. The two 10 head models offer a choice of three and five litre hoppers according to individual piece sizes and dump volumes with top speeds of 70 and 60 weighments per minute (wpm) respectively. The 14 head model with three litre hoppers delivers higher speeds up to 100wpm as well as the availability of improved weighing combinations for smaller piece counts.

All three versions offer an extremely rugged and durable construction with hardware- resistant urethane coated parts that reduce collision and abrasion damage and noise, and a reinforced impact-resistant inlet chute and dispersion table. The Ishida loadcell controlled dispersion table also ensures a regular and consistent product flow, while an alternative photo-eye control is used for larger and heavier products. The impact-resistant pool, weigh and timing hoppers feature an anti-leak design to reduce the risk of leakage of smaller products, and a 45-degree discharge chute provides a gentler product transfer.

To maximise weighing speed and accuracy, the Ishida RVE weighers incorporate several advanced technology features from Ishida’s top-of-the-range RV multihead weighers, including programmable digital filtering and advanced automatic feeder adjustment.

A high-processing speed ROHS-compliant RCU (Remote Control Unit) offers intuitive simple-to-use controls for fast set-up and adjustments. The clear and easy-to-read screen prevents operator errors and simplifies procedures to minimise downtime and maximise production efficiencies. Plug and play USB data import/export and Ethernet connectivity ensure easy data management.

In addition, the weighers are pre-configured for the new generation of ‘smart’ factories and feature as standard Ishida’s unique Sentinel™ customer care software Reporting Pack. This provides users with remote access to live machine performance and emailed summary reports that deliver actionable information to enable rapid decisions to be taken at any time. The system is also connected to Ishida’s Technical Engineering Support team so that external help can be quickly provided if required.

Manufacturing & Engineering Magazine | The Home of Manufacturing Industry News