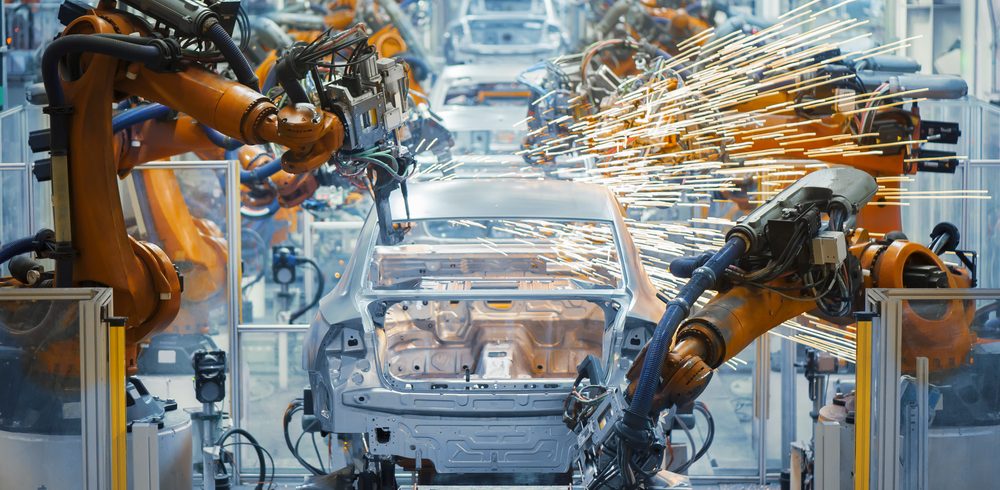

Luxury car maker Aston Martin is reportedly considering a switch to the use of more robots in its manufacturing processes to lower cost and boost profitability.

Remarks by CEO Andy Palmer at a Financial Times conference suggest that the company is prepared to make the switch for parts of its production processes such as the assembly line or paint shop. Palmer said Aston Martin “will need further robotisation” to move into the black.

The newspaper noted that Aston Martin currently uses a single robot at its Gaydon car factory. The robot is part of the glueing process and is, appropriately, named ‘James Bonder’.

However, the FT report says the loss-making company is now planning more investment in production technology in the coming years, including 3D â or additive – printers that can manufacture specialist parts.

Palmer also told the FT conference that Aston Martin cars “need to be predominantly built by hand” to maintain the company’s premium appeal, for example in areas such as the hand-stitching of seat materials.

Aston Martin recently commenced production of its DB11 model, the first core car launched under an extensive renewal and extension of its product portfolio the luxury carmaker’s six-year ‘Second Century Plan’. After the DB11, which replaces the DB9, Aston Martin is planning to follow with a new Vantage and then new Vanquish.

However, the big change to the luxury sportscar company’s business model comes with the new DBX crossover which will be made at a new plant in Wales. CEO Andy Palmer also stresses that Aston Martin is on a journey to becoming an established luxury brand, rather than simply a maker of luxury sportscars.